An oil-electric self-hybrid propulsion system applied to inland waterway transport ships

A power propulsion system and self-mixing technology, which is applied in the field of ship power system, can solve the problems of low propulsion efficiency, low propeller efficiency, and high requirements for automatic operation, achieve good economic and social benefits, reduce energy consumption and exhaust emissions, and improve Effects on Safety and Reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

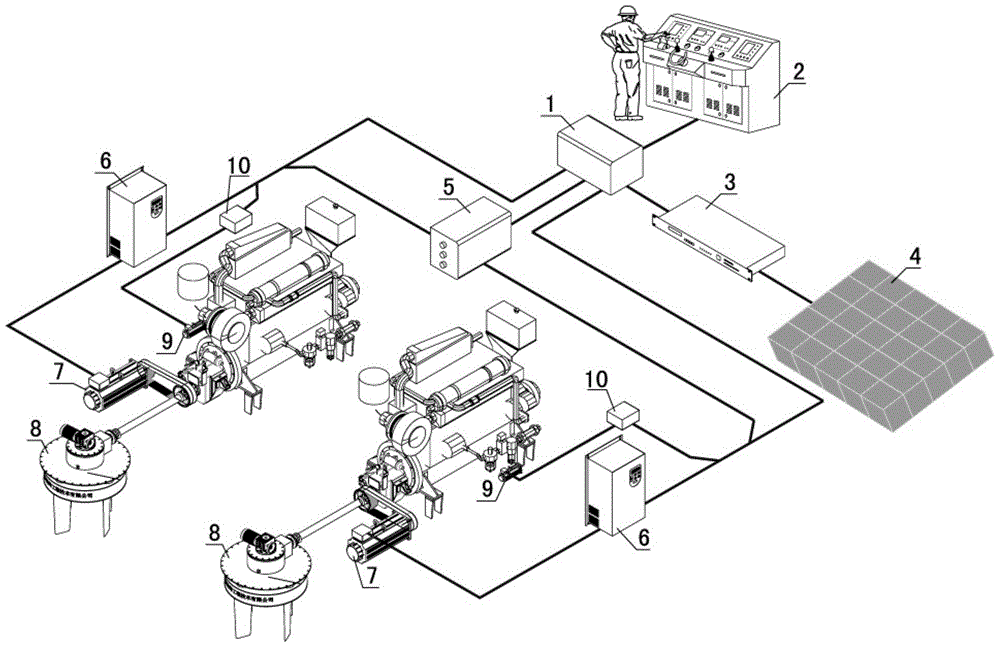

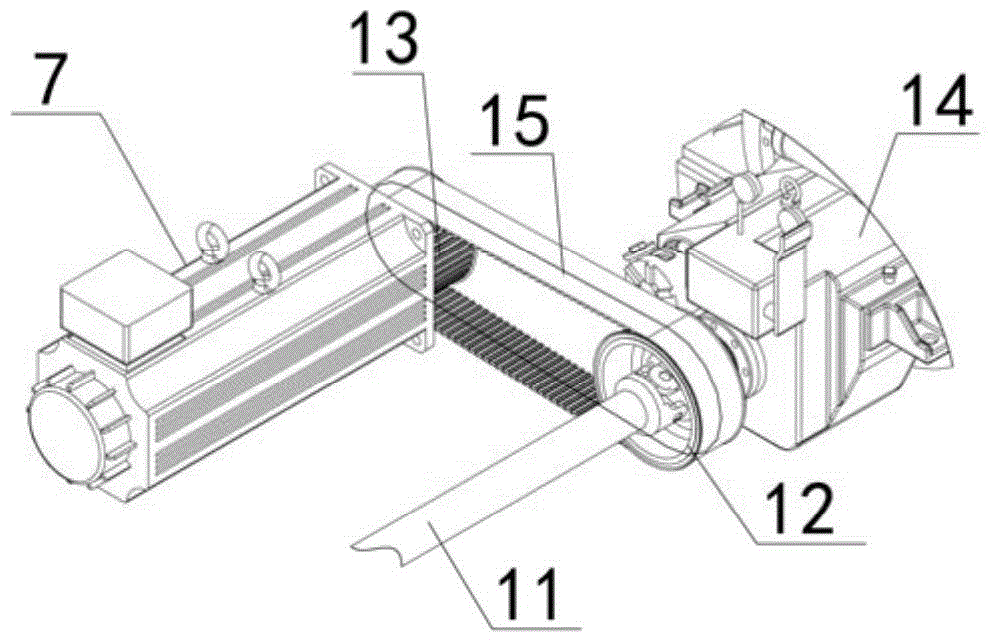

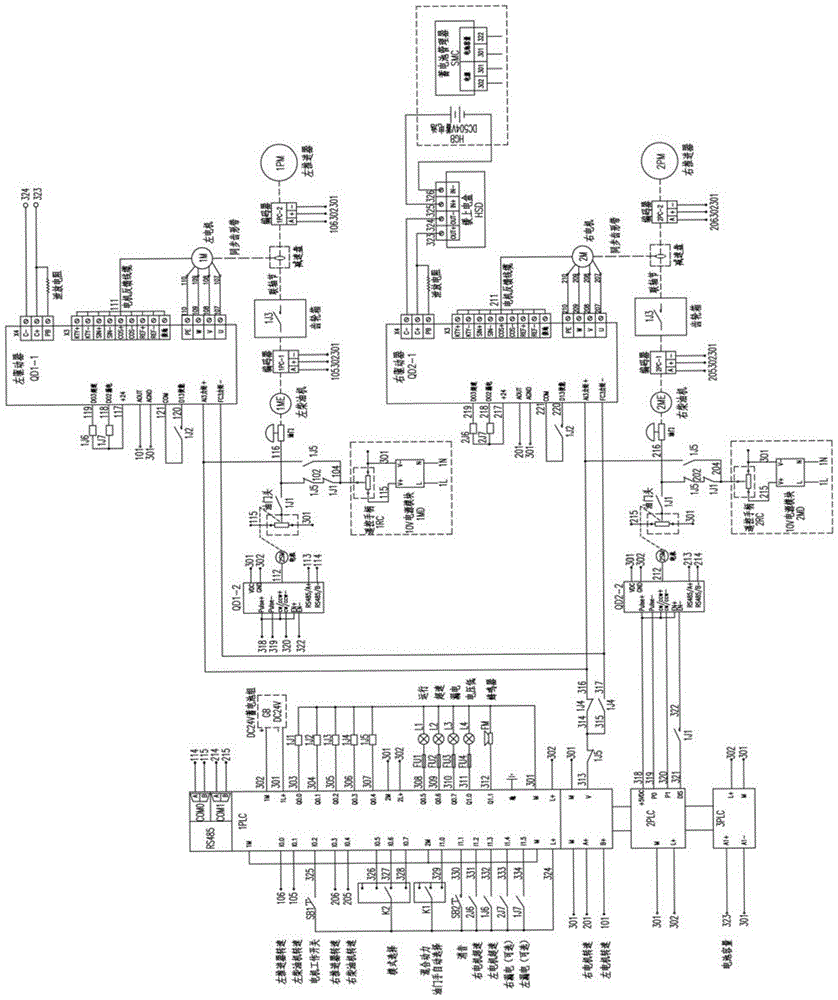

[0077] The oil-electric self-hybrid propulsion system of the present invention is a novel hybrid propulsion form in which the power source is automatically switched according to the operating condition of the ship and the load change of the main engine. The system mainly includes two parts, such as figure 1 , 2 As shown, one part is the propulsion part of diesel engine, which is composed of diesel engine (with automatic speed regulating mechanism), reduction gearbox, shafting, differential type marine flat-rotating propulsion device, etc.; the other part is electric propulsion part, which is composed of shore power charging device, Auxiliary diesel generator set, power battery, battery manager, driver, motor / generator, frequency conversion controller, etc., and the two parts are connected together by a synchronous toothed belt.

[0078]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com