shaft drive foldable bicycle

A folding bicycle and shaft transmission technology, applied in the field of transportation, can solve the problems of loss of wheel rotation, heavy, inconvenient to carry, etc., to achieve the effect of reducing the failure rate, reducing the loss rate, and occupying a small area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

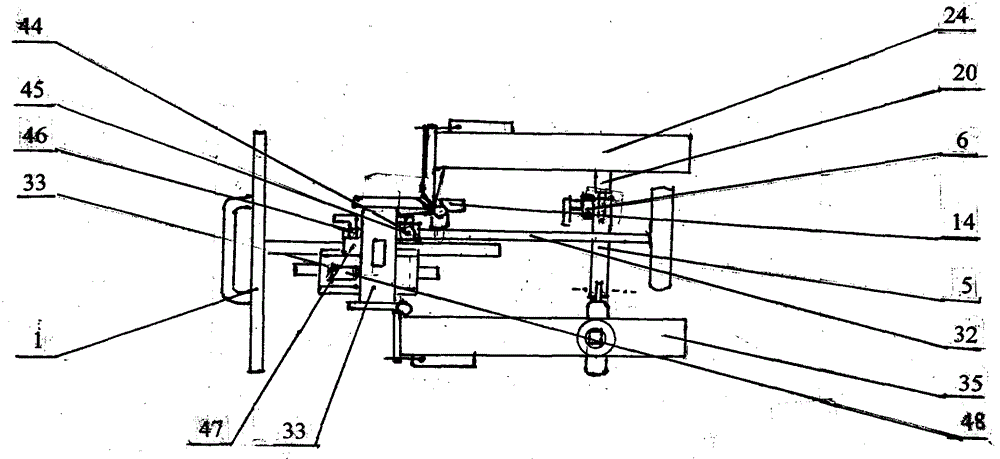

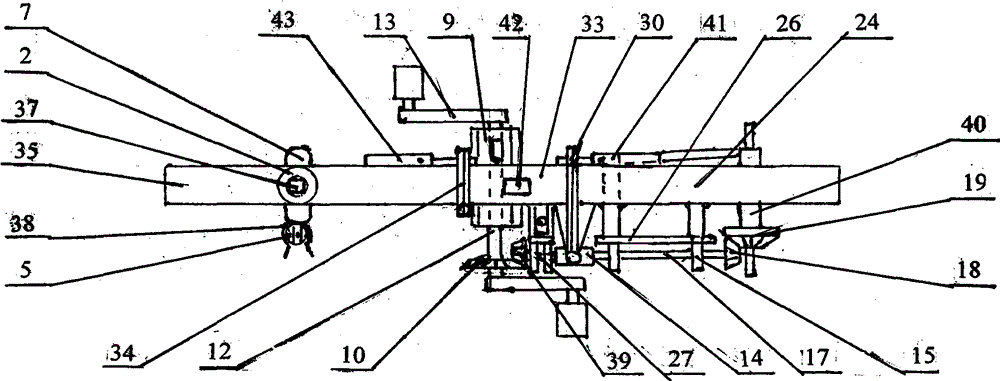

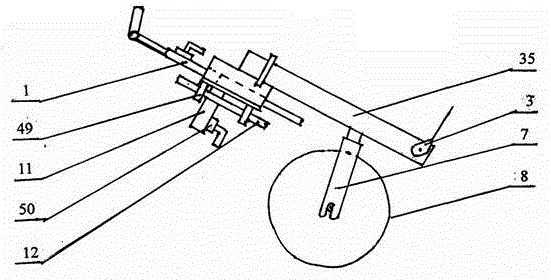

[0006] Specific implementation mode one: (see Figure 1 to Figure 6 ) This embodiment consists of a handlebar assembly 1, a rotating and fixing device 2, an outer circle and an inner square rotating tube 4, a front fork 7, a front wheel assembly 8, a central axis bracket 9, a middle bevel gear 10, and a central axis 12 , large crutch pedal assembly 13, universal joint 14, rear wheel assembly 16, rear drive shaft 17, rear drive shaft bevel gear 18, buckle flywheel and bevel gear assembly 19, rear fork 21, rear Frame 24, front drive shaft 27, rear widened and reinforced hinge 30, seat assembly 32, middle frame 33, front hinge 34, front frame 35, front drive shaft bevel gear 39, rear axle assembly 40. Rear tightening lock 41, front tightening lock 43; it is characterized in that the front interior of the front frame 35 is provided with a rotating and fixing device 2, and the outer circle and inner square rotating tube 4 is arranged inside the rotating and fixing device 2, The up...

specific Embodiment approach 2

[0007] Specific implementation mode two: (see Figure 1 to Figure 5 ) The difference between this embodiment and the specific embodiment one is that the front end of the front frame 35 and the rear end of the rear frame 24 are respectively provided with luggage racks 3 that can be lifted, and a handlebar is provided inside the central axis bracket 9. Assembly slanting pipe 48, the lower end of the handlebar assembly 1 is inserted into the handlebar assembly slanting pipe 48, fixed by the handlebar assembly slanting fixing device 51 arranged outside the central axis bracket 9, the center axis support 9 The bottom is fixed with the universal wheel insertion tube 11, and the universal wheel insertion tube 11 is inserted into the universal wheel insertion tube 11, and is fixed by the universal wheel fixing device 50 arranged on the universal wheel insertion tube 11 outside. Other compositions and connection methods are the same as those in Embodiment 1.

specific Embodiment approach 3

[0008] Specific implementation mode three: (see Figure 1 to Figure 6 ) The difference between this embodiment and the second embodiment is that the rear two sides of the rear frame 24 are fixed with shelf shaft tubes 25, the two ends of the movable shelf 23 are inserted into the shelf shaft tube 25, and one end of the shelf pole 53 is inserted into In the shelf branch pipe 22, the other end of the shelf pole 53 is movably fixed on the outside of the movable shelf 23, and the outside of the movable shelf 23 is fixed with a shelf pole fixing buckle 55 in addition, and the external setting of the reverse flywheel and bevel gear assembly 19 A gear cover 54 is provided. Other compositions and connection methods are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com