Device for continuously converting glycerine into lactic acid by using hydrothermal reaction

A technology for hydrothermal reaction and lactic acid, applied in the field of chemical equipment and waste recycling, can solve the problems of limited volume of reaction tubes, difficult to realize batch production, and multi-manpower, and achieve the effect of saving manpower and stable production rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

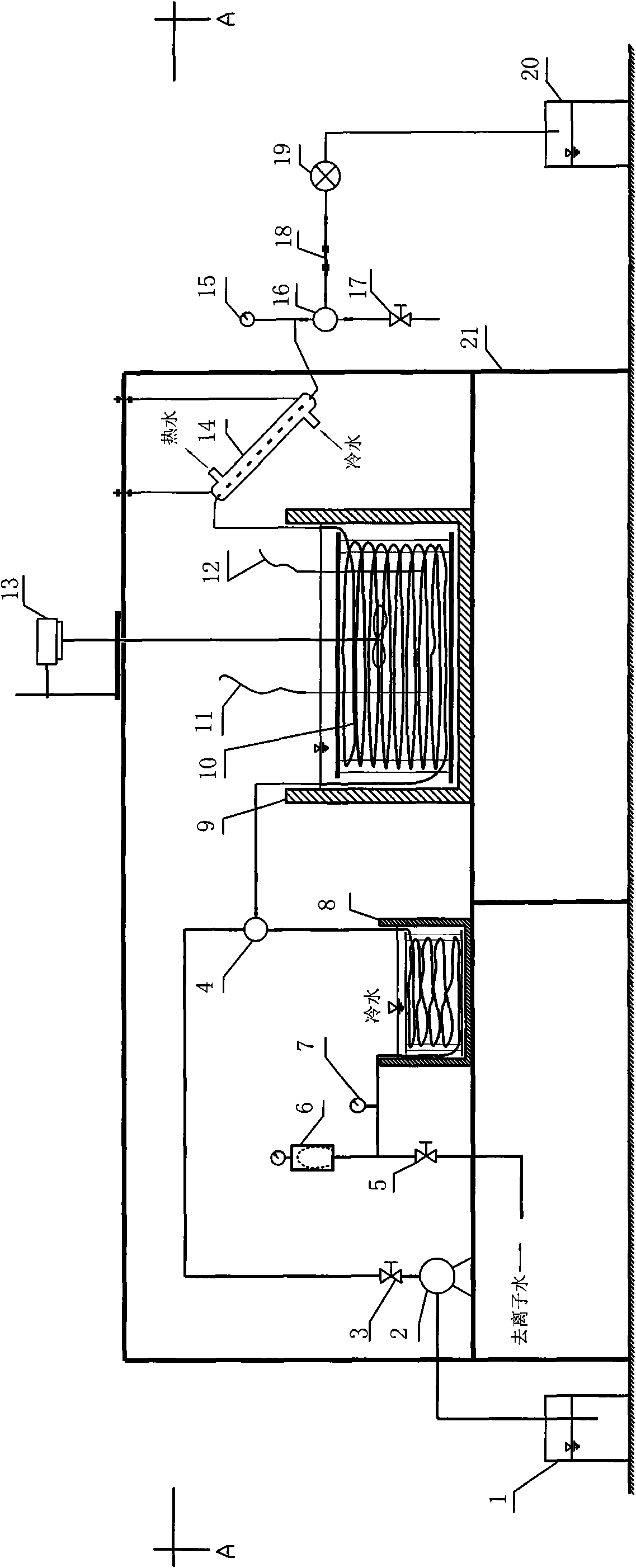

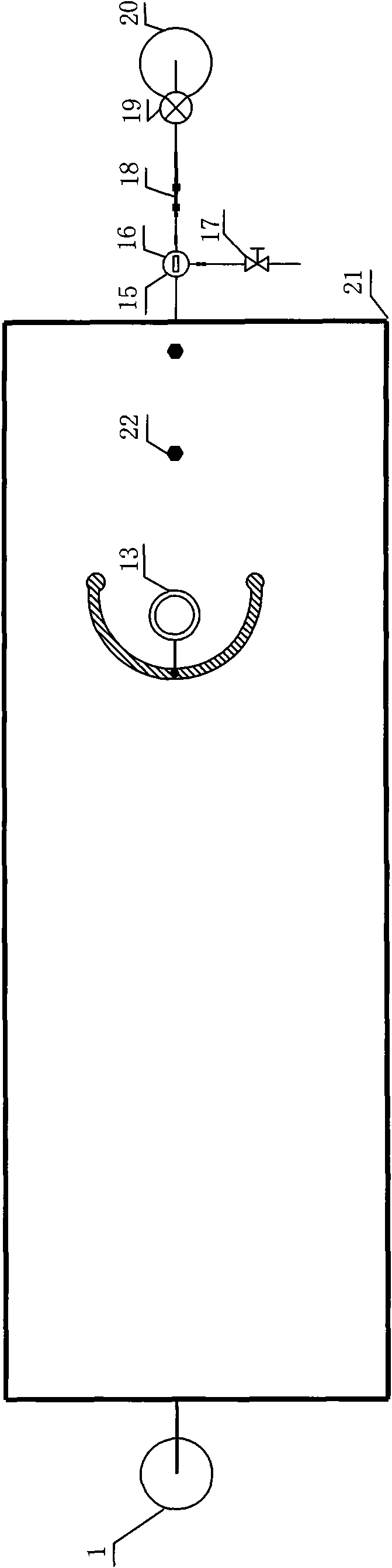

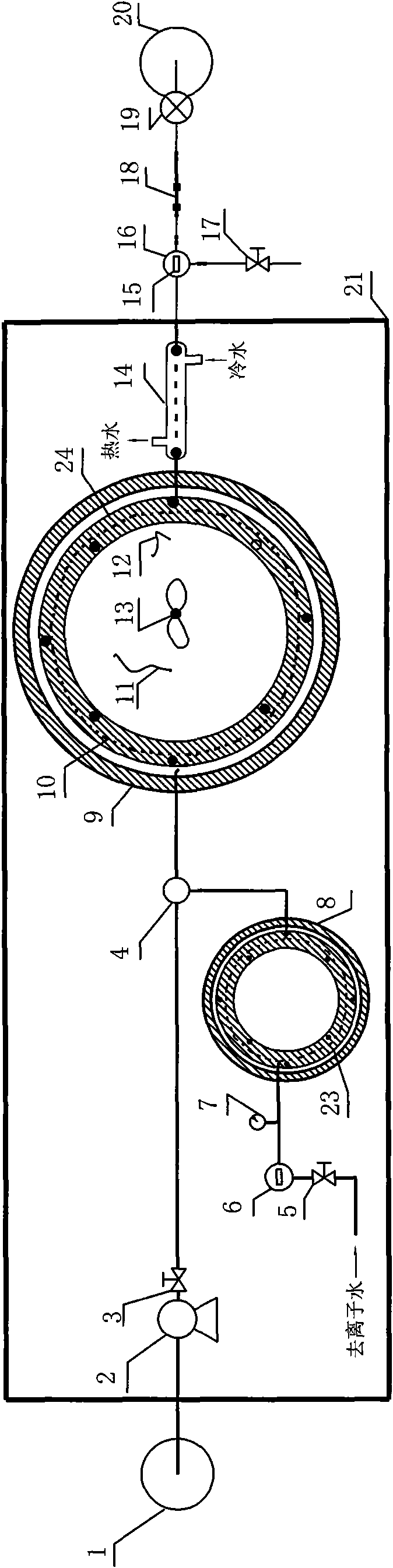

[0023] see Figure 1-4 .

[0024] The invention is a continuous hydrothermal conversion device for converting crude glycerin, a by-product of biodiesel, into lactic acid, and its purpose is to realize the conversion and utilization of crude glycerin, the main by-product of biodiesel. Glycerin comes from a biodiesel company in Shanghai. Biodiesel is produced by microbial fermentation, and glycerol is the main by-product. After the crude glycerol is skimmed off scum and impurities, it is neutralized by acid and alkali to adjust to a glycerol solution with a glycerin content of about 10 mg / L, and then NaOH solid is added to a concentration of 16.47 mg / L to prepare a mixed solution and put it into the present invention. In the sampling container 1 of the continuous hydrothermal reaction device, the sampling container 1 is connected to the inlet of the high-pressure metering pump 2 through a polytetrafluoroethylene pipe, and the high-pressure metering pump 2 is fixedly installed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com