Radial drilling device for shaft sleeve parts

A technology of radial drilling and parts, which is applied in the direction of drilling templates, positioning devices, boring/drilling, etc. for workpieces, and can solve problems such as unreliable positioning and the inability to compensate for the influence of indexing accuracy between indexing pairs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

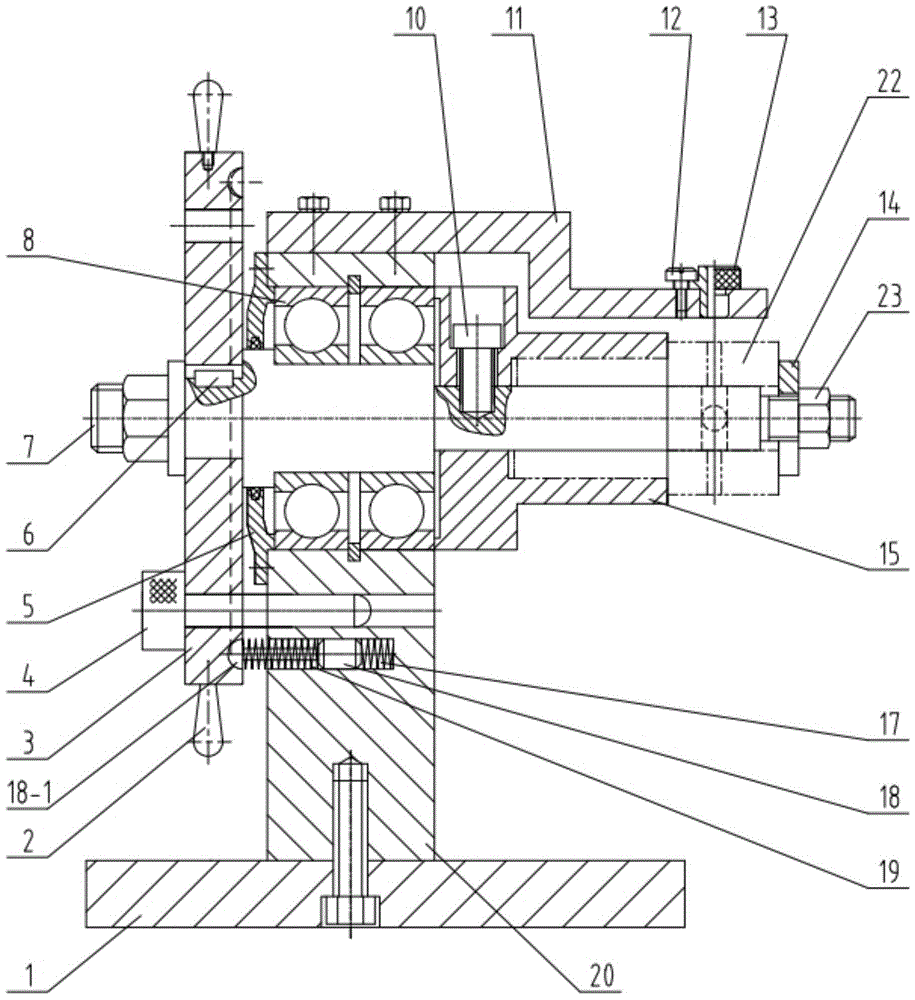

[0013] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

[0014] Such as figure 1 As shown, a radial drilling device for shaft sleeve parts, which includes a clamp body 20, a drilling module assembly, a positioning mandrel 7, a positioning mechanism and an indexing mechanism for shaft sleeve parts, and the positioning mandrel 7 is rotatable Supported on the clamp body 20, the bushing type parts positioning mechanism is installed on the positioning mandrel 7 so that the bushing type parts 22 are locked on the positioning mandrel 7, and the drilling mold assembly is installed on the top of the clamping body 20 for alignment. Shaft sleeve parts 22 are drilled. The indexing mechanism includes positioning pin 4, indexing plate 3, indexing pin 18 and return spring. Indexing plate 3 is set on the positioning man...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com