A production process of semi-aluminized glass microspheres and its bead brushing device

A glass microbead and aluminized technology, applied in the field of reflection, can solve the problems of small quantity and unstable quality, and achieve the effects of high retroreflection performance, good dry cleaning performance and high collection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

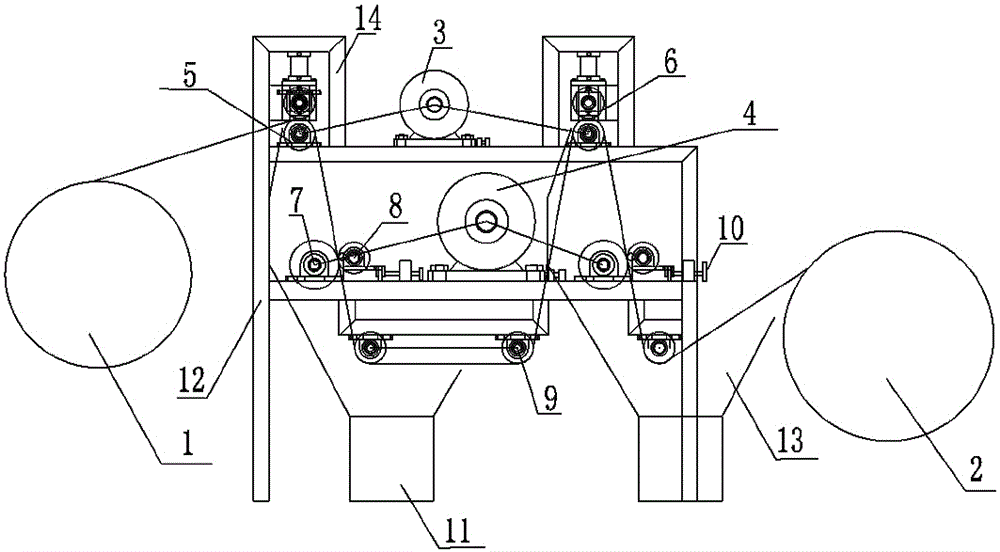

[0015] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

[0016] A semi-aluminized glass microsphere production process, the surface of the glass microsphere is coated with 1 / 2 of the aluminized layer, and it comprises the following steps:

[0017] S1: Bead planting process: apply the plant glue on the corona surface of the PET film on the coating machine, dry, and then evenly distribute the glass beads on the bead plant glue, and wind up to obtain the bead plant film.

[0018] S2: Vacuum aluminum plating process: put the plant film obtained in step 1 into a vacuum aluminum plating machine for aluminum plating, the thickness of the aluminum layer is controlled at 300-1000 angstroms, and an aluminum-coated plant film is obtained.

[0019] S3: Bead brushing process: Unwind the aluminum-plated bead-planting film obtained in step 2 on the bead brushing device, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com