Sharp inclination fully mechanized coal face open-off cut square supporting method

A technology of fully mechanized mining face and square support, applied in mining equipment, earthwork drilling, wellbore lining, etc., can solve the problems of high labor intensity, high safety threat, low efficiency, etc. The effect of less damage and improved bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

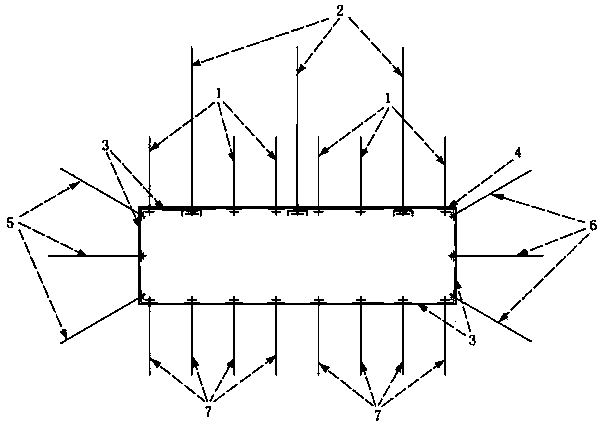

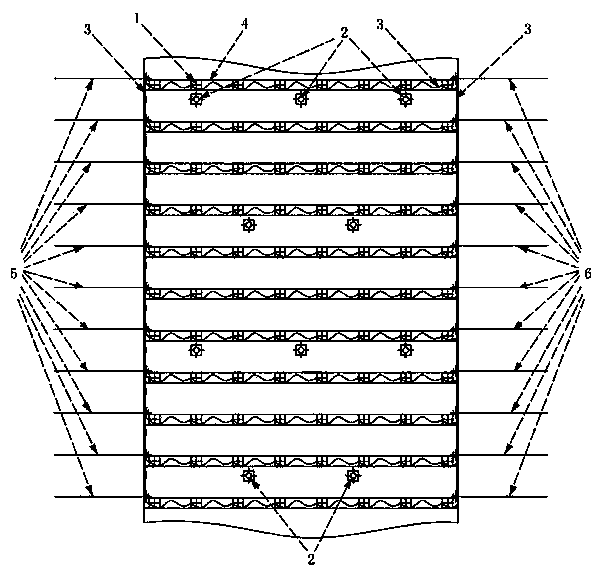

[0016] The cutout span in this example is 7.5m, figure 1 with figure 2 It is a structural elevation and plan view of the present invention. The section shape of the open cut hole is rectangular, and its section size: width × height = 7.5m × 2.3m.

[0017] A four-sided support method for opening a cut hole in a steeply inclined fully mechanized mining face, the implementation steps are as follows:

[0018] a. Roof support: combined support with anchor, mesh and cable, that is, the top anchor (1) adopts resin anchor (φ=18mm, L=2m) with diamond-shaped metal mesh (3), steel ladder (4) and anchor cable (2) (φ=15.24mm, L=5m) for support, the spacing and row spacing of the top anchors (1) are both 1m, and each top anchor (1) is equipped with 2 pieces of CK2350 resin anchoring agent in the hole, and the anchor The cable (2) spacing is 3m, the row spacing is 2.5m, and the arrangement is misplaced. Each anchor cable (2) is filled with 4 pieces of ZK2350 resin anchoring agent in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com