Energy-saving type sewage sludge harmless treatment method

A harmless treatment of sewage sludge, applied in dehydration/drying/concentrated sludge treatment, sludge treatment through temperature control, combustion methods, etc., can solve the problem of low freezing efficiency, low recovery rate of waste heat from incineration, increased pollution Mud treatment volume and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

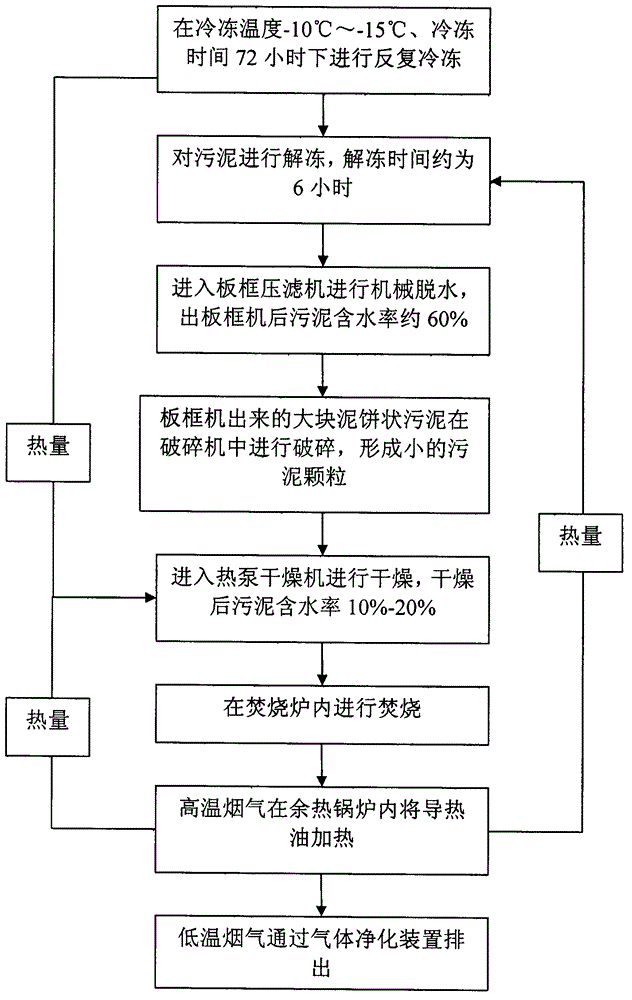

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0027] As shown in the figure, an energy-saving sewage sludge harmless treatment method of the present invention comprises the following steps:

[0028] 1) The sludge in the sludge freezing container is continuously frozen by the freeze-drying energy circulation system, and the sludge is thawed after continuous freezing, so that the freezing and thawing is repeated many times. This step is based on the drying device 3 and the freeze-drying energy circulation system. The freeze-drying energy cycle system described includes a compressor 5, an evaporator 6, a condenser 7 and a first heat exchanger 8 arranged in the sludge freezing container 4, the gas outlet of the compressor 5 is connected with the condenser 6, and the condenser 7 is connected to the evaporator 6 through the throttling element 9, and the evaporator 6 is connected to the intake en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com