Three-dimensional flower-shaped titanic acid material formed by assembling lamelleted nanosheets and synthesizing method of three-dimensional flower-shaped titanic acid material

A layered nano, three-dimensional flower-like technology, applied in nanotechnology, titanium compounds, nanotechnology, etc., can solve the problems of unfavorable photogenerated charge transport and separation, limit the synthesis and application of titanic acid, and affect the catalytic performance of materials, etc., to achieve high Prospect of commercial application, stable product structure and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Add 1.00g of P123 into a 100mL beaker, place the beaker on a magnetic stirrer, add 36.75mL of acetic acid to raise the temperature to 40°C, and stir until completely dissolved. Add 1.00mL of TBT into the beaker, stir to dissolve and then stop stirring to obtain a white milky product. The above emulsion was left to stand for 2 hours to continue the reaction, and the obtained white emulsion solution was transferred to a 50mL reaction kettle, and placed in a thermostat at 150°C for 24 hours. After cooling, the white precipitate solution was suction-filtered, filtered and washed repeatedly with ethanol, and the obtained white precipitate was dried at 60° C. for 24 hours to obtain a three-dimensional flower-like titanic acid material assembled from layered nanosheets with a yield of 30%.

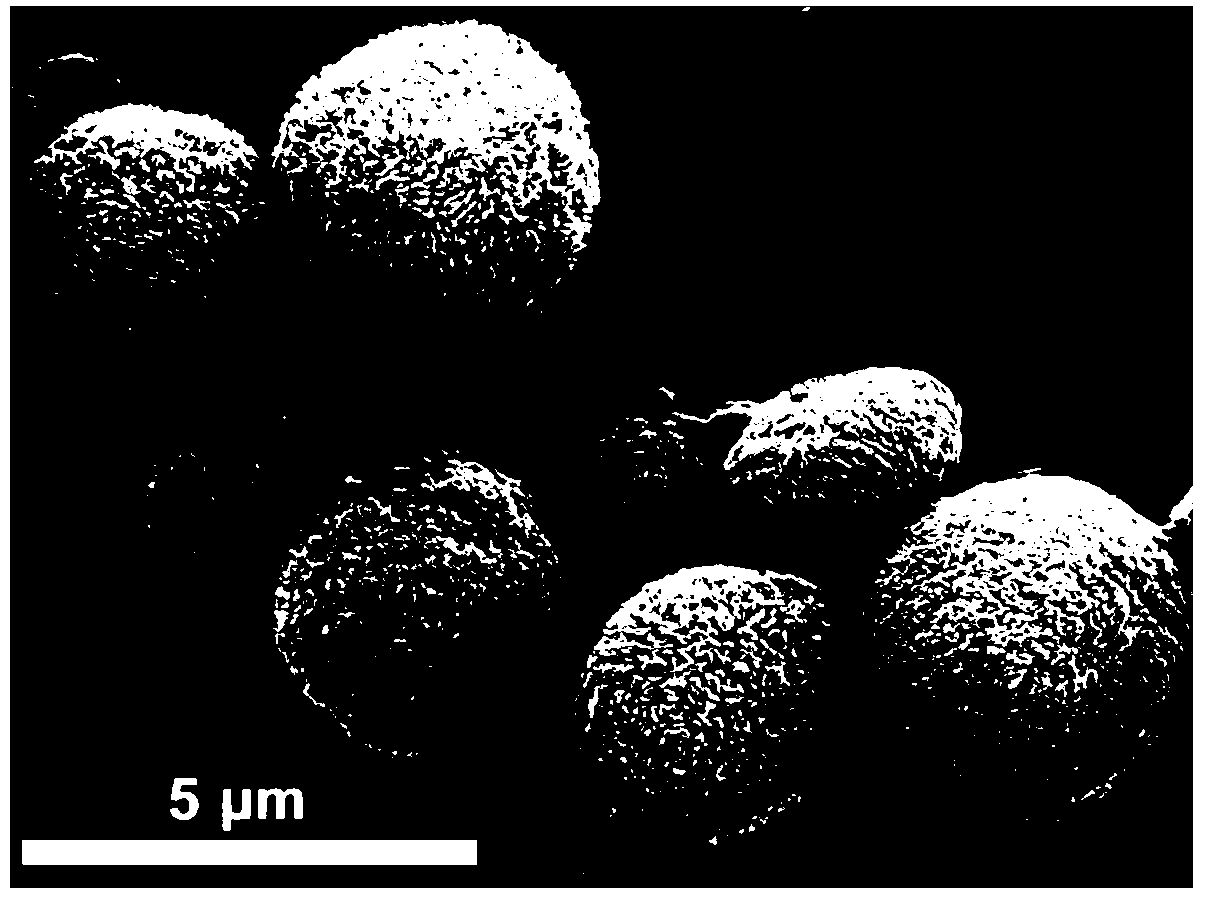

[0030] figure 1 The SEM image of the three-dimensional flower-shaped titanic acid material prepared in this embodiment, figure 2 The HRTEM figure of the layered nanosheets in the three-...

Embodiment 2

[0032] Add 1.00g of P123 into a 100mL beaker, place the beaker on a magnetic stirrer, add 36.75mL of acetic acid to raise the temperature to 40°C, and stir until completely dissolved. Add 1.00mL of TBT into the beaker, stir to dissolve and then stop stirring to obtain a white milky product. The above emulsion was left to stand for 24 hours to continue the reaction, and the obtained white emulsion solution was transferred to a 50mL reaction kettle, and placed in a 150°C thermostat for 24 hours. After cooling, the white precipitate solution was suction-filtered, filtered and washed repeatedly with ethanol, and the obtained white precipitate was dried at 60°C for 24 hours to obtain a three-dimensional flower-like titanic acid material assembled from layered nanosheets with a yield of 28%.

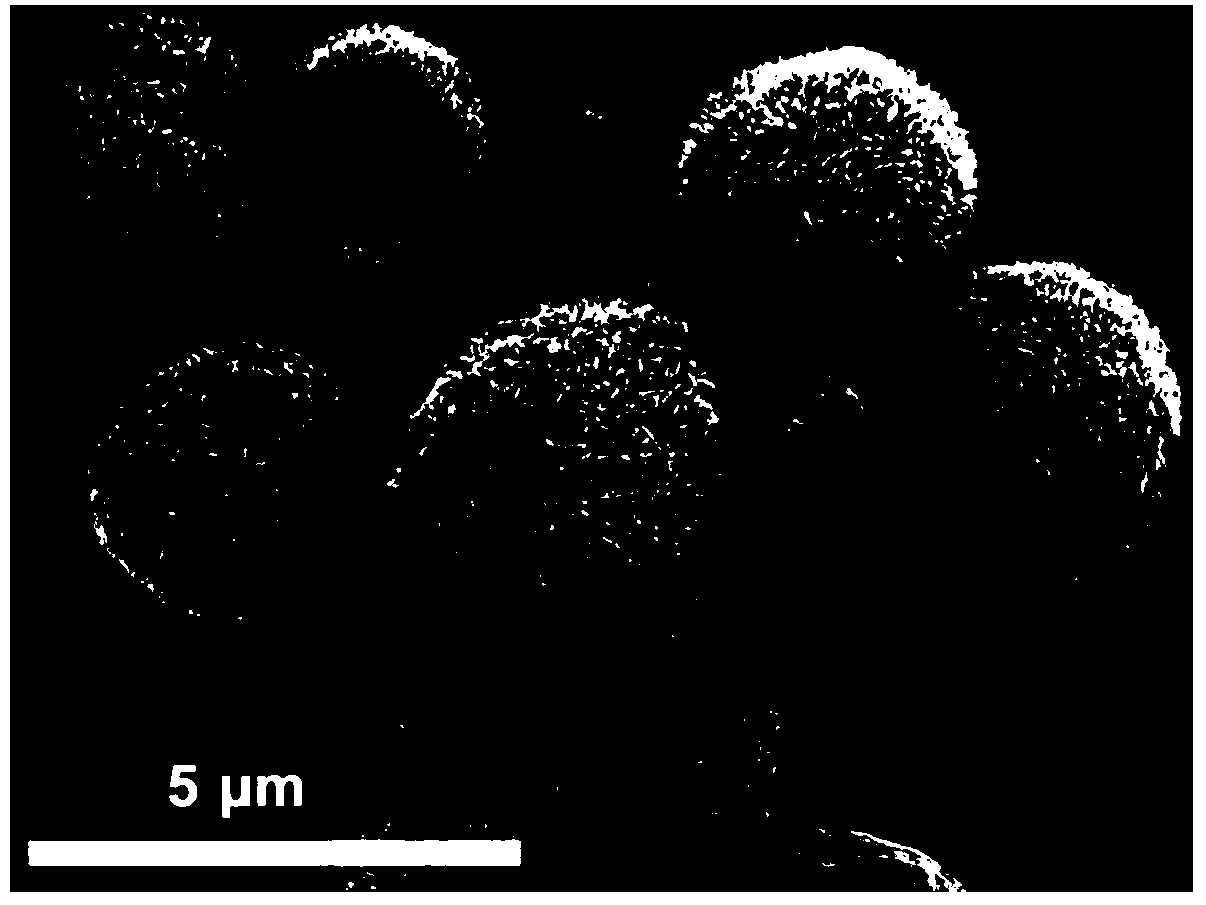

[0033] image 3 The SEM image of the three-dimensional flower-like titanic acid material assembled by layered nanosheets prepared for this example, Figure 4 For the TEM picture of the three...

Embodiment 3

[0035] Add 1.00g of P123 into a 100mL beaker, place the beaker on a magnetic stirrer, add 36.75mL of acetic acid to raise the temperature to 40°C, and stir until completely dissolved. Add 1.00mL of TBT into the beaker, stir to dissolve and then stop stirring to obtain a white milky product. The above emulsion was allowed to stand for 96 hours of continuous reaction, and the obtained white emulsion solution was transferred to a 50 mL reaction kettle, and placed in a thermostat at 150°C for 24 hours. After cooling, the white precipitate solution was suction-filtered, filtered and washed repeatedly with ethanol, and the obtained white precipitate was dried at 60° C. for 24 hours to obtain a three-dimensional flower-like titanic acid material assembled from layered nanosheets with a yield of 35%.

[0036] Figure 5 The SEM image of the three-dimensional flower-like titanic acid material assembled by layered nanosheets prepared for this example, Image 6 In order to prepare the H...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com