Casting method and device for braking disc body and braking disc body made by same

A technology of brake disc and disc body, applied in the direction of brake disc, manufacturing tools, casting and molding equipment, etc., can solve the problems of no feeding system, shrinkage cavity and shrinkage of castings, etc., to reduce production costs, reduce production costs, The effect of increasing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

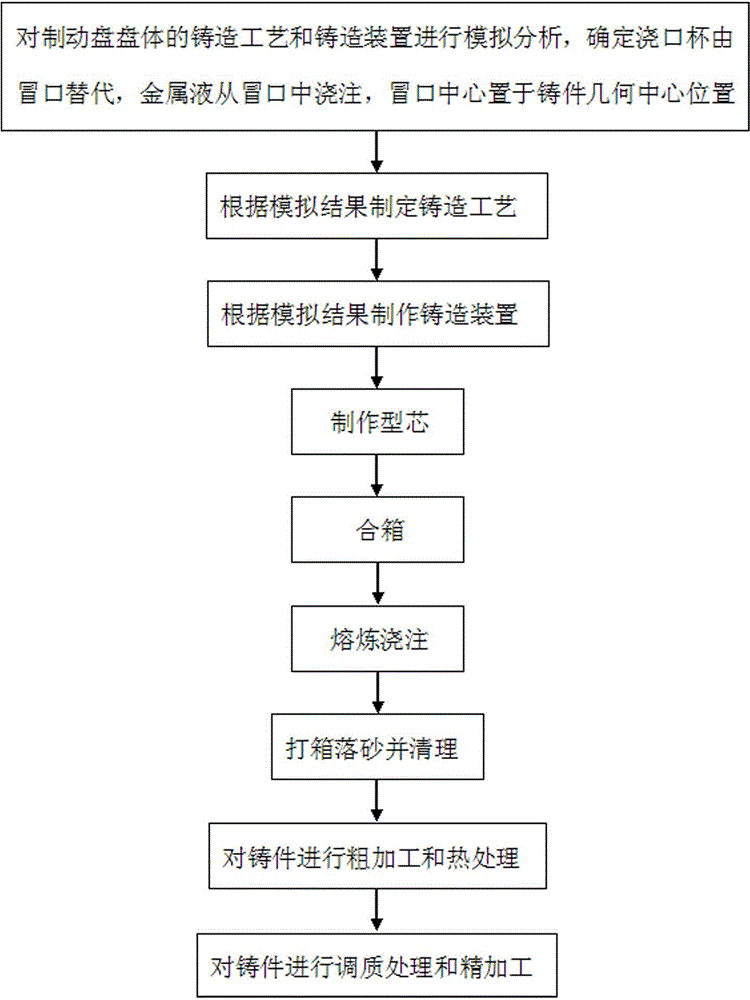

[0053] Taking the high-speed train cast steel brake disc body (with an outer diameter of 600 mm and an inner diameter of 240 mm) as an example, the process flow of the casting method suitable for the production of the molding line is as follows: figure 1 As shown, it includes the following steps in sequence:

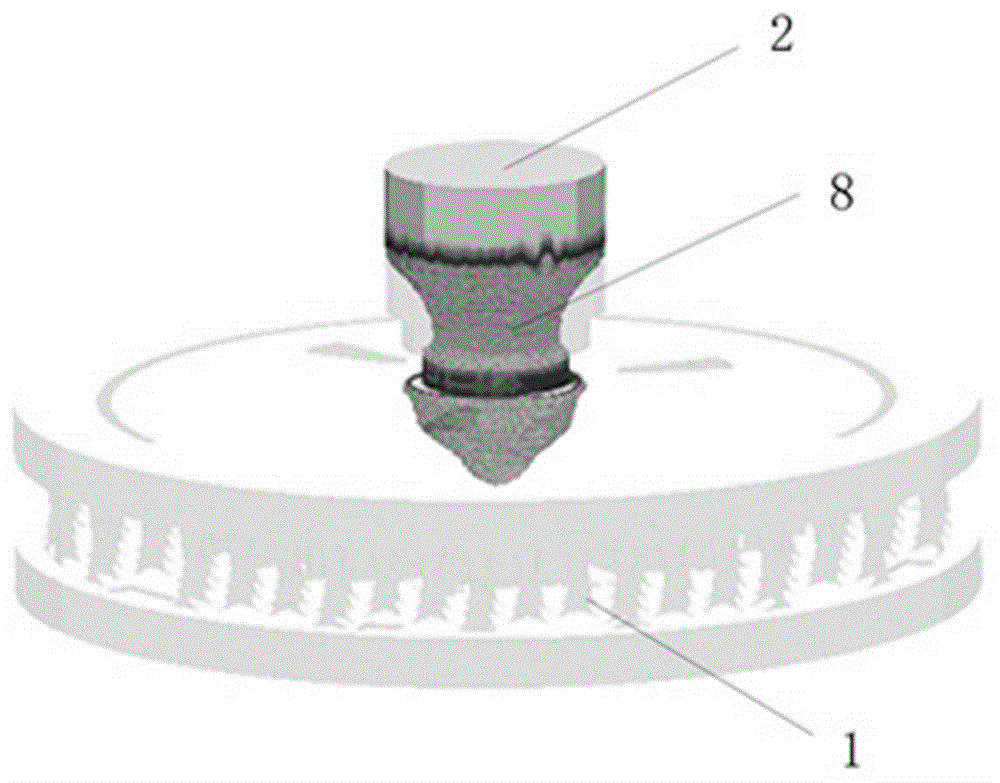

[0054] (1) The casting process and casting device of the brake disc body are simulated and analyzed by computer simulation software, and the positions of the gating system and the feeding system are determined. The sprue cup of the gating system is replaced by the riser 2 of the feeding system, and the metal The liquid is directly poured from the riser 2, the center of the riser 2 is placed at the geometric center of the casting 1, and the molten metal flows from the geometric center of the casting 1 to the surroundings;

[0055] (2) According to the simulation analysis results of step (1), formulate the casting process of the brake disc body, adopt the method of introdu...

Embodiment 2

[0072] Taking the high-speed train cast steel brake disc body (with an outer diameter of 610 mm and an inner diameter of 240 mm) as an example, the process flow of the casting method suitable for the production of the molding line is as follows: figure 1 As shown, it includes the following steps in sequence:

[0073] (1) The casting process and casting device of the brake disc body are simulated and analyzed by computer simulation software, and the positions of the gating system and the feeding system are determined. The sprue cup of the gating system is replaced by the riser 2 of the feeding system, and the metal The liquid is directly poured from the riser 2, the center of the riser 2 is placed at the geometric center of the casting 1, and the molten metal flows from the geometric center of the casting 1 to the surroundings;

[0074] (2) According to the simulation analysis results of step (1), formulate the casting process of the brake disc body, adopt the method of introdu...

Embodiment 3

[0090]Taking the high-speed train cast steel brake disc body (with an outer diameter of 600 mm and an inner diameter of 260 mm) as an example, the casting method and casting device suitable for the production of the molding line are basically the same as in the first embodiment.

[0091] The riser 2 is cylindrical in shape with a diameter of 150 mm and a height of 150 mm. The pouring speed of molten metal in riser 2 is 25 cm / s, and the flow speed in casting 1 is 27 mm / s.

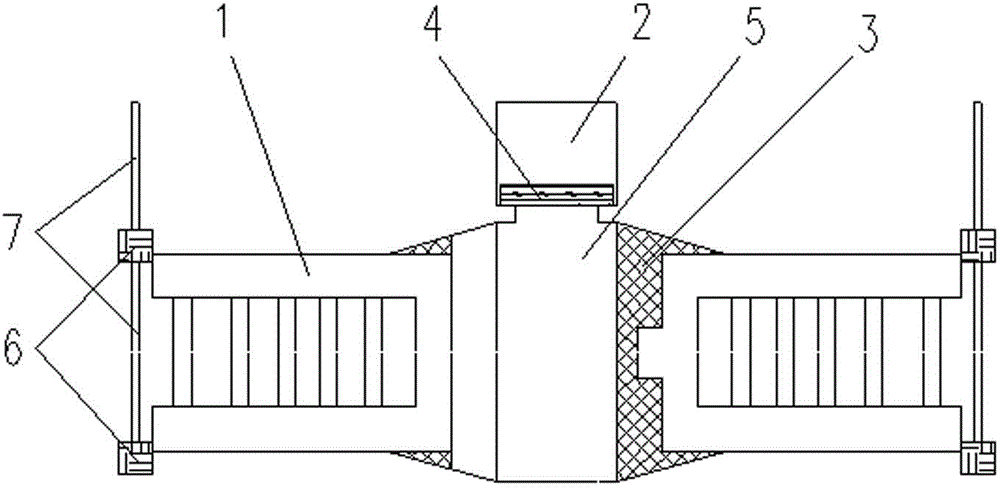

[0092] The outer side of the riser 2 is covered with a layer of ceramic fiber; the rectifying and filtering device 4 is made of ceramic bricks; the subsidy 2 is made of heat-insulating refractory material. There are six slag collecting exhaust rods 7, which are evenly distributed on the outside of the casting 1, and are connected with the slag collecting overflow sheets 6 on the upper and lower edges.

[0093] Non-destructive testing is carried out on castings, and at the same time, it meets the inspect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com