a centrifugal clutch

A technology for centrifugal clutches and clutch sleeves, applied in the field of clutches, which can solve problems such as high machining accuracy requirements, cumbersome machining, and complex structures, and achieve the effects of low machining accuracy requirements, stable and reliable work, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

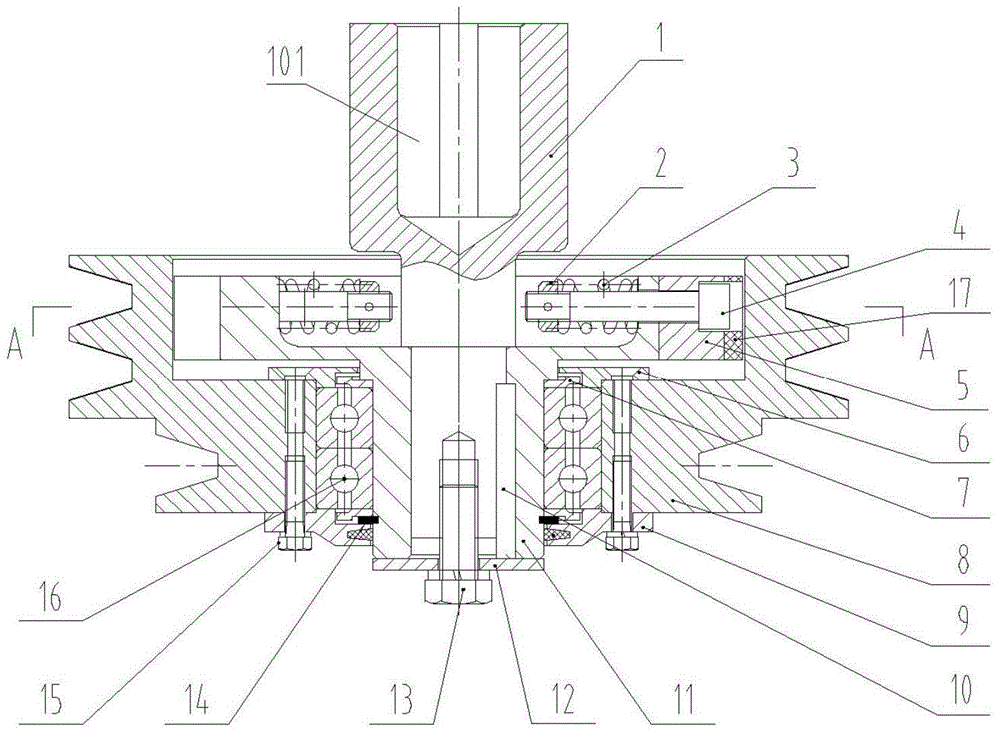

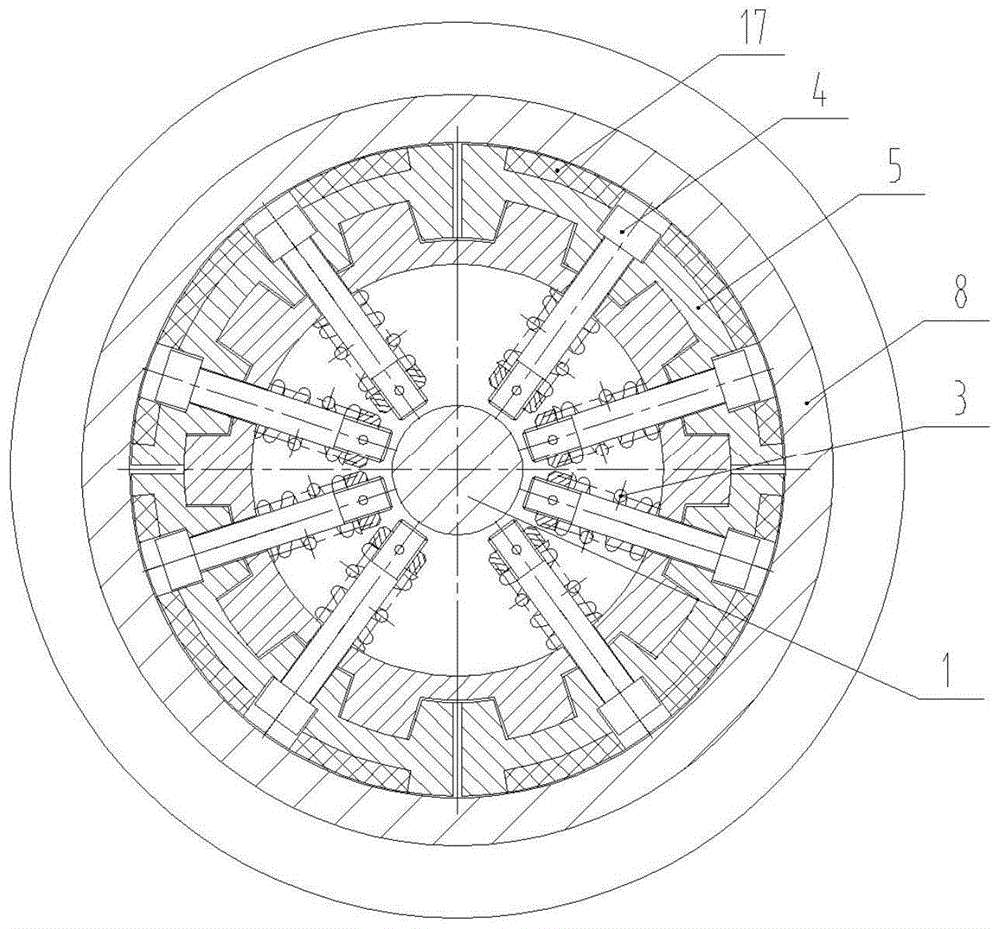

[0023] like figure 1 and figure 2 As shown, a centrifugal clutch involved in the present invention includes a driving part, a centrifugal body and a driven part. The connecting socket 101 is used for connecting the engine. A clutch cover 11 is fitted on the driving shaft 1 and connected with a key 10. The driven member is a pulley 8 and is installed outside the clutch cover 11 through a bearing 16. The centrifugal body is a plurality of brake blocks 5 and is arranged on the clutch Between the sleeve 11 and the inner hole of the pulley 8, as a non-limiting preference, there are four brake blocks 5 . Each brake block 5 is respectively engaged with the clutch sleeve 11 through splines, so as to improve the reliability of transmission. Friction plates 17 are inlaid on the outer wall of each brake block 5 to increase the friction between the brake block 5 and the pulley 8 and improve the reliability of transmission.

[0024] Elastic connecting components are respectively provi...

Embodiment 2

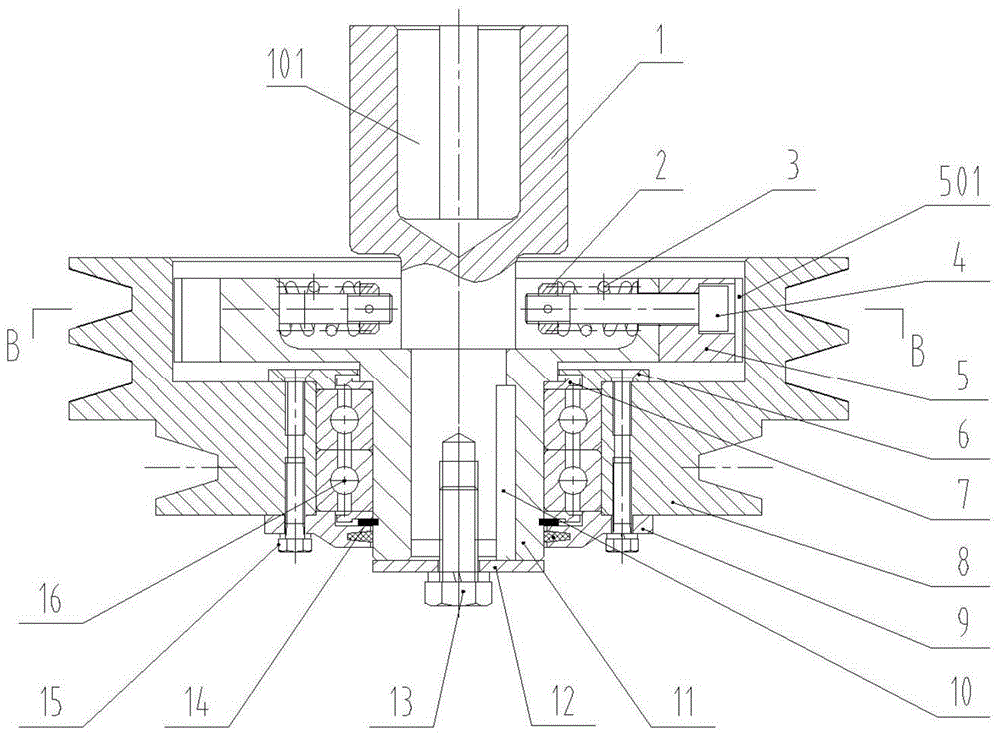

[0029] like image 3 and Figure 4 As shown, a centrifugal clutch involved in the present invention includes a driving part, a centrifugal body and a driven part. The connecting socket 101 is used for connecting the engine. A clutch sleeve 11 is set on the driving shaft 1 and connected by a key. The driven member is a pulley 8 and is installed outside the clutch sleeve 11 through a bearing 16. The centrifugal body is a plurality of brake blocks 5 and is arranged on the clutch sleeve. Between 11 and the inner hole of the pulley 8, as a non-limiting preference, there are four brake blocks 5 . Each brake block 5 is respectively engaged with the clutch sleeve 11 through splines, so as to improve the reliability of transmission. The outer wall of each brake block 5 is processed with straight-toothed small teeth 501 to increase the friction between the brake block 5 and the pulley 8 and improve the reliability of transmission.

[0030] Other structures of this embodiment are the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com