Ultrasonic intensified leaching method for refractory gold ores and ultrasonic intensified gold leaching stirrer

A technology of ultrasonic strengthening and gold mining, applied in the field of hydrometallurgy, can solve difficult, difficult, and further improvement problems, and achieve the effects of reducing investment, convenient operation, and saving equipment space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

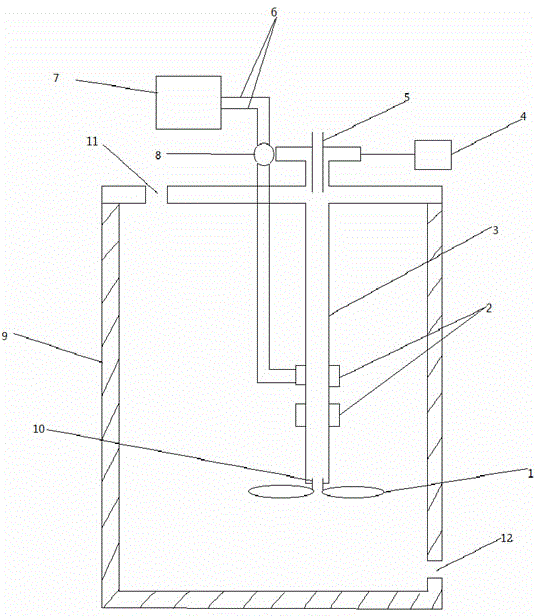

Image

Examples

Embodiment 1

[0022] For a refractory gold ore, the gold grade is 3.23g / t, and the leaching rate obtained by direct conventional cyanidation leaching process is 12.7%. First mix 400g of gold ore powder with a particle size of less than 200 mesh and 600ml of water in a 1L beaker, then add 20g of sodium hydroxide; turn on the mechanical stirring and adjust the stirring speed to 500 rpm, the air volume to 120L / hour, and stir After uniformity, the opening frequency is 20.0kHz, the power is 2kW, and the sound intensity is 3.3W / cm 3 Ultrasonic device carries out ultrasonic intensive pretreatment. The cycle of ultrasonic pretreatment is 5 minutes of ultrasonic pretreatment and 1 minute off. During ultrasonic pretreatment, 1ml of hydrogen peroxide is added every half hour; after 3 hours of treatment, it is filtered, washed and dried for later use. Take 150g of ore sample treated with sodium hydroxide, add 600ml of water, 1g of calcium oxide and 1.8g of sodium cyanide. cm 3 Ultrasonic equipment is...

Embodiment 2

[0028] For a refractory gold ore, the gold grade is 3.23g / t, and the leaching rate obtained by direct conventional cyanidation leaching process is 12.7%. First mix 400g of gold ore powder with a particle size of less than 200 mesh and 600ml of water in a 1L beaker, then add 60g of sodium hydroxide; turn on the mechanical stirring and adjust the stirring speed to 500 rpm, and the air volume to 180L / hour, stir After uniformity, the opening frequency is 20.0kHz, the power is 2kW, and the sound intensity is 3.3W / cm 3 Ultrasonic device for ultrasonic pretreatment. The cycle of ultrasonic pretreatment is 5 minutes of ultrasonic pretreatment and stop for 1 minute. During ultrasonic pretreatment, 1ml of hydrogen peroxide is added every half hour. After 1 hour of treatment, it is filtered, washed and dried for later use; Add 600ml of water, 1g of calcium oxide and 1.8g of sodium cyanide to 150g of the ore sample treated with sodium hydroxide. 3 Ultrasonic equipment is used for ultraso...

Embodiment 3

[0034] For a refractory gold ore, the gold grade is 3.23g / t, and the leaching rate obtained by direct conventional cyanidation leaching process is 12.7%. First mix 400g of gold ore powder with a particle size of less than 200 mesh and 600ml of water in a 1L beaker, then add 60g of sodium hydroxide; turn on the mechanical stirring and adjust the stirring speed to 500 rpm. The air flow rate is 180L / hour, and after stirring evenly, the opening frequency is 20.0kHz, the power is 2kW, and the sound intensity is 3.3W / cm 3 Ultrasonic device for ultrasonic pretreatment. The cycle of ultrasonic pretreatment is 5 minutes of ultrasonic pretreatment and stop for 1 minute. During ultrasonic pretreatment, 1ml of hydrogen peroxide is added every half hour. After 1 hour of treatment, it is filtered, washed and dried for later use; Add 600ml of water, 1g of calcium oxide and 2.7g of sodium cyanide to 150g of the ore sample treated with sodium hydroxide. 3 Ultrasonic equipment is used for ultr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com