Sulfur-dioxide-free full-juice fermented orange wine and its production process

A technology of sulfur dioxide and whole juice, applied in the direction of microorganisms, preparation of alcoholic beverages, methods based on microorganisms, etc., can solve the problems of complex action and no basic process mode, etc., to reduce water activity, ensure normal alcohol fermentation, and enhance antiseptic effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

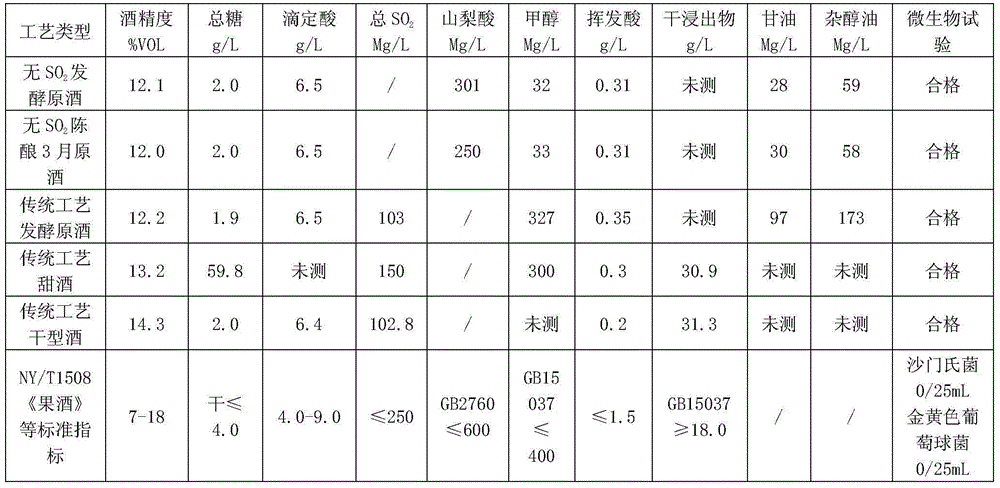

Image

Examples

Embodiment 1

[0071] A full-juice fermented orange wine without sulfur dioxide, prepared by the following method:

[0072] 1) Disinfection of the original fruit: the orange fruit (navel orange) in the factory is poured into the fruit pond, soaked in 300ppm bleaching powder solution or 0.02% potassium permanganate solution for about 10 minutes, disinfected, and then washed into the scraper elevator through the fruit ditch;

[0073] 2) Fruit selection, scrubbing and cleaning: the original fruit enters the roller fruit selection machine through the scraper hoist. After the birth and rotten fruit are manually selected, the orange fruit is transferred to the drum-type fruit brushing machine to brush the fruit and rinse with high pressure water. After scrubbing Enter the surf fruit washing machine to clean the raw fruit with tap water;

[0074] 3) Juicing from the original fruit: the cleaned orange fruit enters the orange fruit peeling and juicer to squeeze the juice through the scraper elevator, and th...

Embodiment 2

[0118] A full-juice fermented orange wine without sulfur dioxide, prepared by the following method:

[0119] 1) Disinfection of the original fruit: the orange fruit (navel orange) in the factory is poured into the fruit pond, soaked in 600ppm bleaching powder solution or 0.05% potassium permanganate solution for about 10 minutes, disinfected and washed into the scraper elevator through the fruit ditch;

[0120] 2) Fruit selection, scrubbing and cleaning: the original fruit enters the roller fruit selection machine through the scraper hoist. After the birth and rotten fruit are manually selected, the orange fruit is transferred to the drum-type fruit brushing machine to brush the fruit and rinse with high pressure water. After scrubbing Enter the surf fruit washing machine to clean the raw fruit with tap water;

[0121] 3) Juicing from the original fruit: the cleaned orange fruit enters the orange fruit peeling and juicer to squeeze the juice through the scraper elevator, and the turb...

Embodiment 3

[0165] A full-juice fermented orange wine without sulfur dioxide, prepared by the following method:

[0166] 1) Disinfection of the original fruit: the orange fruit (navel orange) in the factory is poured into the fruit pond, soaked in 400ppm bleaching powder solution or 0.04% potassium permanganate solution for about 10 minutes, disinfected and washed into the scraper elevator through the fruit ditch;

[0167] 2) Fruit selection, scrubbing and cleaning: the original fruit enters the roller fruit selection machine through the scraper hoist. After the birth and rotten fruit are manually selected, the orange fruit is transferred to the drum-type fruit brushing machine to brush the fruit and rinse with high pressure water. After scrubbing Enter the surf fruit washing machine to clean the raw fruit with tap water;

[0168] 3) Juicing from the original fruit: the cleaned orange fruit enters the orange fruit peeling and juicer to squeeze the juice through the scraper elevator, and the turb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com