Resin composition, film, and substrate containing same

A technology of resin composition and base material, applied in the direction of synthetic resin layered products, transportation and packaging, electrical components, etc., can solve the problems of signal delay, loss, signal transmission speed and quality that cannot be ignored, and achieve the improvement of glass transition temperature , The effect of reducing the dielectric constant and dielectric loss factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

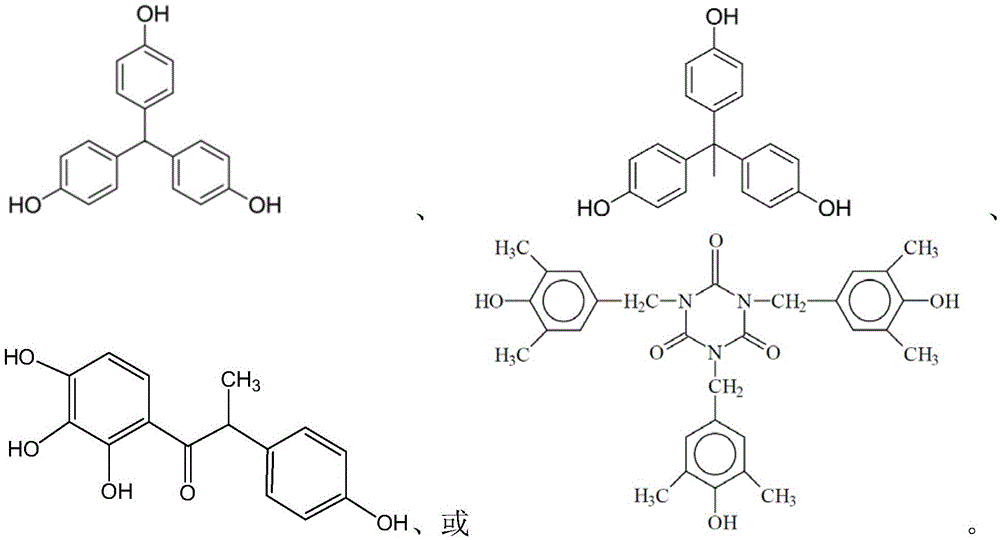

[0042] Take monovalent copper bromide (3.42g, 24mmol) into a 1000ml double-necked flask, add dibutylamine (314ml, 1690mmol), 1,3,5 trihydroxybenzene (6g, 47.5mmol) and toluene (500mL) as a solvent, heated to 50°C under an oxygen system (flow rate: 3L / min), and stirred for 20 minutes. Then, the monomers 2,6-bismethylphenol (58.1 g, 470 mmol), 2-allyl-6-methylphenol (22 g, 96 mmol) and a little hydrochloric acid were added and precipitated in a large amount of methanol. The obtained precipitated polymer was collected by gravity filtration, dried and sealed at 50° C. to obtain polyphenol ether compound 1 with a yield of 52%. The dielectric constant (Dk) of the polyphenol ether compound 1 = 3.05; the dielectric loss factor (Df) = 0.004; the glass transition temperature (Tg) = 196°C. The above reaction can be expressed as the following formula:

[0043]

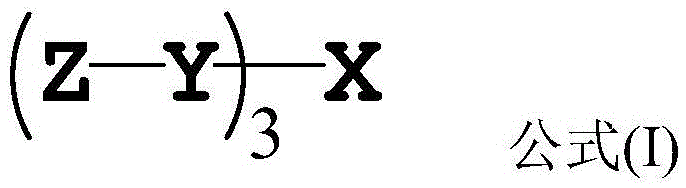

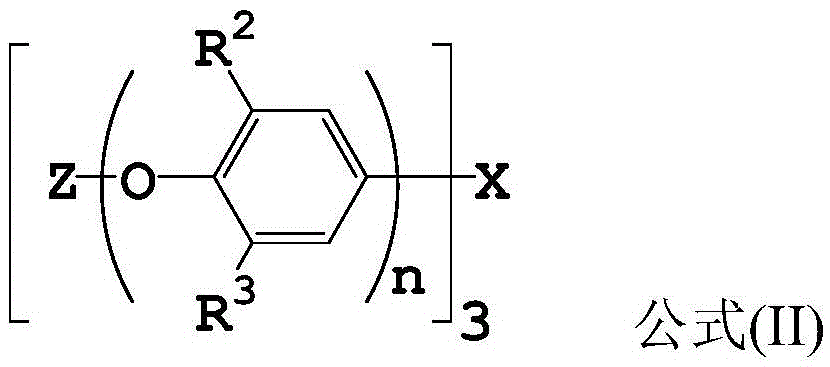

[0044] Polyphenol ether compound 1 (where Y can be the same or different groups. Y has i repeating units And j repeating units ...

preparation example 2

[0048] Put epichlorohydrin (10 g, 100 mmol) into a 100 ml double-necked flask, and add the above-mentioned polyphenol ether compound 1 (1 g, 0.154 mmol) for terminal group modification. The reaction was heated to 60°C under a nitrogen system. Then, 2-methoxyethanol (1 g, 13 mmol) was added, and then the solvent was removed by vacuum distillation, dissolved in tetrahydrofuran (THF), and precipitated in methanol. The obtained polymer was collected by gravity filtration, dried and sealed at 50°C to obtain polyphenol ether compound 2; the dielectric constant (Dk) of polyphenol ether compound 2 was 2.91; the dielectric loss factor (Df) was 0.005; Glass transition temperature (Tg) = 190°C. The above reaction can be expressed as the following formula:

[0049] (Among them, Y can be the same or different groups. Y has i repeating units And j repeating units Where i is a positive integer, j is a positive integer, and the sum of i and j is 6 to 300. In addition, the repeating unit a...

preparation example 3

[0053] Take 1 g of the above polyphenol ether compound 1 (0.154 mmol) into a 100 ml double-necked flask, add 10 mL of tetrahydrofuran (THF) solvent, and heat to 60° C. under a nitrogen system. Next, 0.2 g of 50% sodium hydroxide aqueous solution was added, followed by slowly adding p-chloromethyl styrene (0.8 mL, 1.1 mmol). The solution after the reaction was washed with deionized water to remove impurities and salts, and then dissolved in tetrahydrofuran and precipitated in methanol. The precipitated polymer was collected by gravity filtration, and dried and sealed at 50°C to obtain polyphenol Ether compound 3. The above reaction can be expressed as the following formula:

[0054]

[0055] (Among them, Y can be the same or different groups. Y has i repeating units And j repeating units Where i is a positive integer, j is a positive integer, and the sum of i and j is 6 to 300. In addition, the repeating unit as well as It is repeated in random or block fashion. Y is a repe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com