Polyacrylate modified water-based enclosed isocyanate curing agent and preparation method thereof

A technology of blocked isocyanate and polyacrylate, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of difficult isocyanate group movement, reduced curing efficiency, coating performance defects, etc., to achieve low cost and improved appearance , The effect of stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

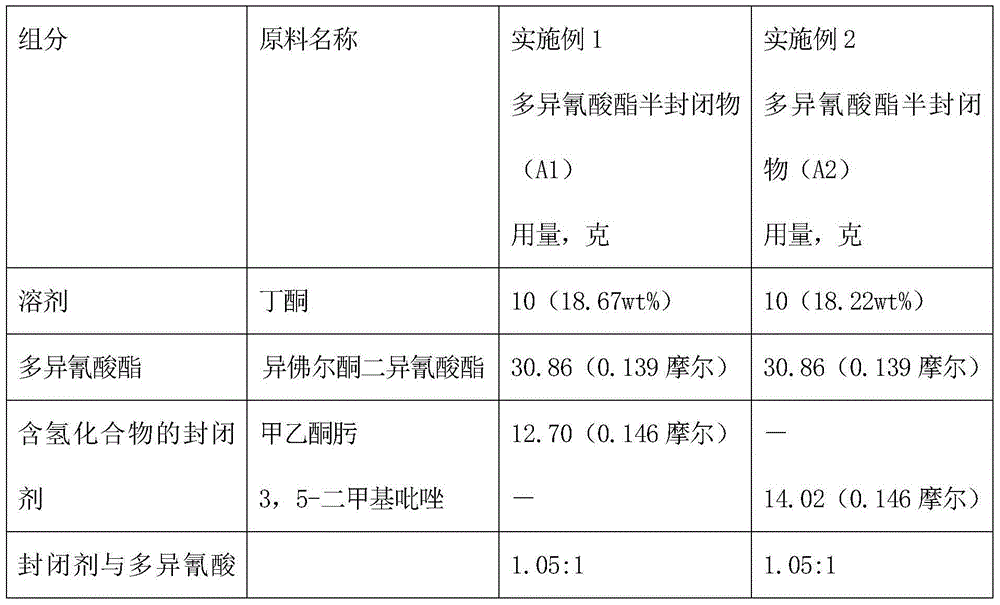

[0042] 2. the concrete operation of preparation embodiment 1 polyisocyanate semi-block (A1)

[0043] With 30.86 grams of isophorone diisocyanate and 10 grams of solvent methyl ethyl ketone as the primer, add 12.70 grams of blocking agent methyl ethyl ketone oxime dropwise at 60 ° C. The molar ratio of blocking agent to polyisocyanate is 1.05:1, and the drop is completed within 2 hours , after the dropwise addition was completed, it was incubated at 60° C. for 5 hours and discharged to obtain a polyisocyanate semi-block (A1), which was stored for future use.

preparation Embodiment 2

[0044] 3. the concrete operation of preparation embodiment 2 polyisocyanate semi-blocks (A2)

[0045] The concrete operation of preparation is identical with embodiment 1, and difference is: the 12.70 gram blocking agent methyl ethyl ketoxime of embodiment 1 is replaced with 14.02 gram blocking agent 3,5-dimethylpyrazole, obtains polyisocyanate half-block (A2) , save for later use.

[0046] (2) Preparation of hydroxyl-containing polyacrylate

[0047] The method for preparing the hydroxyl-containing polyacrylate of the present invention is: the mixture of all monomers, chain transfer agents and initiators is evenly added dropwise to the solvent to carry out free radical polymerization, and the specific operations are as follows:

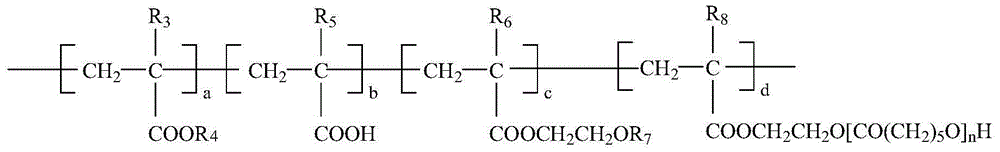

[0048] Using 10-50wt% solvent as a primer, 5-15wt% carboxyl-containing vinyl monomers, 2-20wt% acrylate monomers containing primary or secondary hydroxyl groups, 1-10wt% The ε-caprolactone-modified vinyl monomer containing primary hydroxyl group, 5-...

preparation Embodiment 4

[0069] 2. The specific operation of preparation example 4 polyacrylate modified water-based blocked isocyanate curing agent (D1)

[0070] 53.56 grams of polyisocyanate semi-blocks (A1) (containing residual NCO group 0.132 moles) prepared in Example 1 are mixed with hydroxyl-containing polyacrylate B (containing hydroxyl 0.125 moles), wherein polyisocyanate semi-blocks (A1 ) in the isocyanate group and the mol ratio of the hydroxyl of the hydroxyl-containing polyacrylate (B) is 1.06:1, add the catalyst dibutyltin dilaurate (0.047wt% for A1+B total mass) of 0.1 gram, raise Temperature to 80°C, kept at 80°C for 5 hours, then added 12 grams of neutralizing agent triethylamine (5.6wt% of the total mass of A1+B) to neutralize, at 200 rev / min the stirrer Add 250 g of deionized water (1.17 times the total mass of A1+B) under stirring for emulsification, heat up to 70°C, and distill under reduced pressure to extract the solvent to obtain a polyacrylate modified water-based blocked isoc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com