Process method for extracting chlorogenic acid from blumea riparia(BL.)DC

A process method, the technology of chlorogenic acid, is applied in chemical instruments and methods, the separation/purification of carboxylate, and the preparation of carboxylate, which can solve the problems of low preparation purity, complicated preparation process, and difficult industrial production. Achieve the effects of simple process steps, simple operation and constant yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

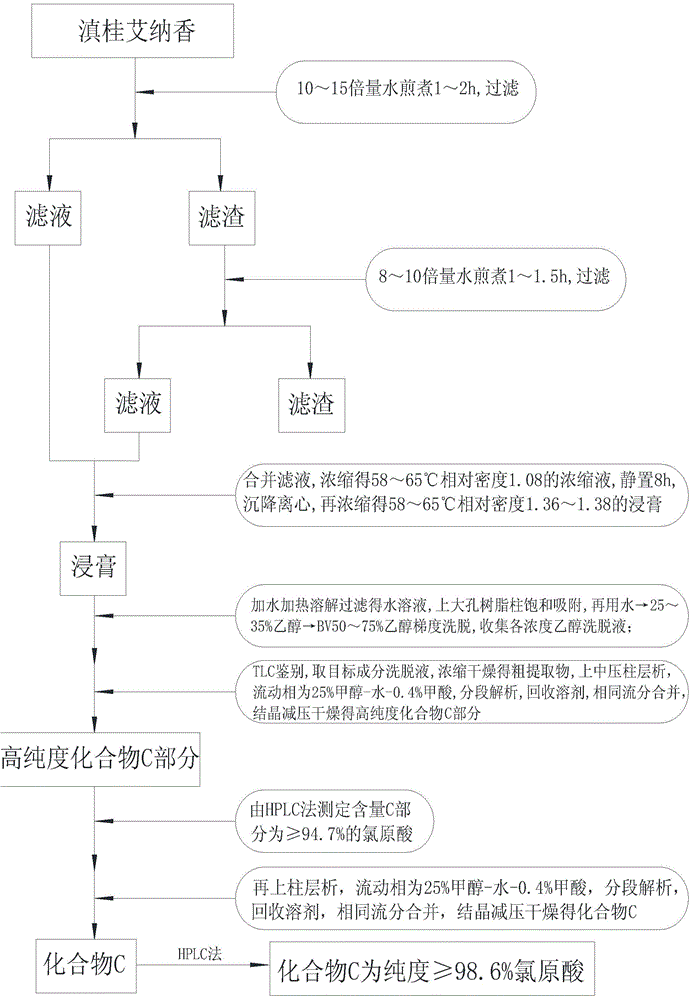

[0034] The process of extracting chlorogenic acid from Ainaxiang osmanthus Dianensis:

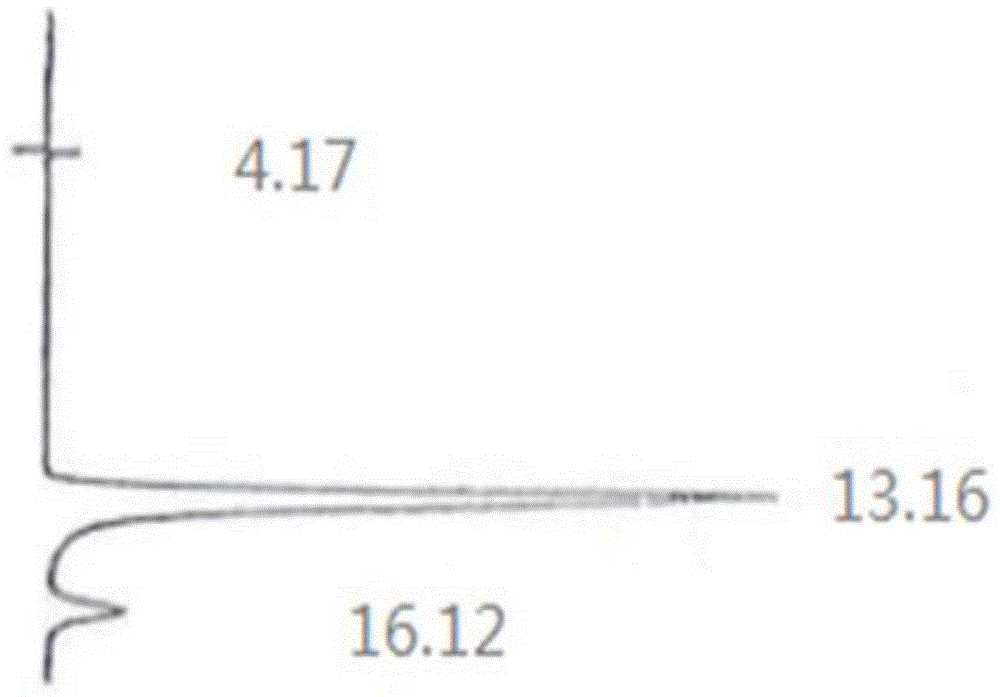

[0035]Put the impurity-removed medicinal material of Yunnan Gui Ainaxiang into an extraction tank, add water to decoct twice, add 10 times the amount of water for decoction for 1.5 hours for the first time, and decoct for 1 hour with 10 times the amount of water for the second time, and control the temperature at 65°C, filter with a 200-mesh filter cloth, combine the filtrate; concentrate the filtrate to a concentrated solution with a relative density of 1.08 at 60°C, move it to a sedimentation tank, let it stand for 8 hours, and process it by sedimentation and centrifugation, take the clarified filtrate and concentrate it to a relative density of 60°C An extract with a density of 1.36; the extract is dissolved in 5 times the amount of water and heated to 65°C, filtered to obtain an aqueous solution of the extract, adjusted to pH 3, added to a polar macroporous resin column for saturated ads...

Embodiment 2

[0037] The process of extracting chlorogenic acid from Ainaxiang osmanthus Dianensis:

[0038] Put the impurity-removed medicinal material of Yunnan Gui Ainaxiang into an extraction tank, add water to decoct twice, add 15 times the amount of water for decoction for 2 hours for the first time, and decoct for 1.5 hours with 10 times the amount of water for the second time, and control the temperature at 80°C, filter with a 230-mesh filter cloth, and combine the filtrates; concentrate the filtrate to a concentrated solution with a relative density of 1.08 at 65°C, move it to a sedimentation tank, and let it stand for 8 hours. An extract with a density of 1.38; the extract is dissolved in 8 times the amount of water and heated at 80°C, filtered to obtain an aqueous solution of the extract, adjusted to pH 5, added to a polar macroporous resin column for saturated adsorption, and the adsorption flow rate is controlled 10ml / min, the total amount of the extract is controlled as 1 time...

Embodiment 3

[0040] The process of extracting chlorogenic acid from Ainaxiang osmanthus Dianensis:

[0041] Put the impurity-removed medicinal material of Yunnan Gui Ainaxiang into an extraction tank, add water to decoct twice, add 12 times the amount of water to decoct for 1.5 hours for the first time, add 8 times the amount of water to decoct for 1 hour for the second time, and control the temperature as follows: 60°C, filter with a 180-mesh filter cloth, and combine the filtrates; concentrate the filtrate to a concentrated solution with a relative density of 1.08 at 58°C, move it to a sedimentation tank, and let it stand for 8 hours. An extract with a density of 1.36; the extract is dissolved in 6 times the amount of water and heated at 70°C, filtered to obtain an aqueous solution of the extract, adjusted to pH 4, added to a polar macroporous resin column for saturated adsorption, and the adsorption flow rate is controlled It is 6ml / min, and the total amount of extract is controlled as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com