Oil-water well stratigraphic reservoir water-injection decontamination filtering self-cleaning device

A filter device and self-cleaning technology, which is applied in the direction of sterilization/microdynamic water/sewage treatment, wellbore/well components, production fluid, etc. wall corrosion and other problems, to achieve the effect of improving the water quality of injection water, solving the costs related to the amount of shutdown maintenance and cleaning engineering, and solving the environmental protection problems of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

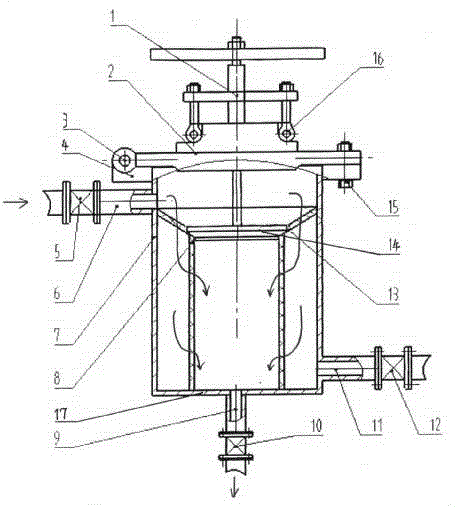

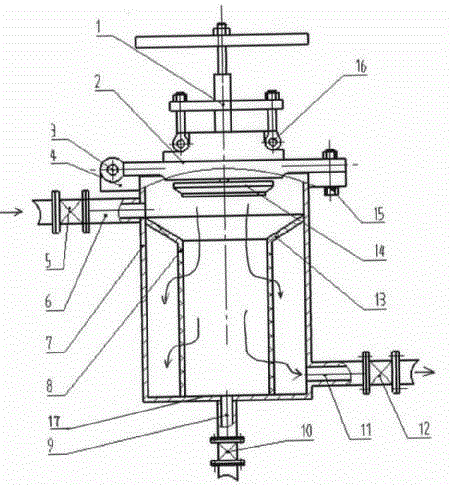

[0009] Detailed description in conjunction with the drawings: As shown in the figure, the actuator 1 is connected to the upper flange bonnet 2 through bolts 16, and one side of the upper flange bonnet 2 is connected to the shell cylinder flange 4 through a pin shaft 3, and the upper flange The bonnet 2 is connected to the flange 4 of the shell cylinder through uniformly distributed bolts 15. The shell cylinder 7 is respectively provided with a water inlet pipe 6 with a water inlet valve 5 on the upper part of the side wall, and a water inlet pipe 6 with a water outlet valve 12 on the lower part of the side wall. The water outlet pipe 11, the sewage outlet pipe 9 with the sewage valve 10 at the head end, the valve stem end of the actuator 1 is connected to the sealing plug 14, the outer shell cylinder 7 is equipped with a copper powder particle sintered filter screen inner cylinder 8, and the inner cylinder The large-diameter end of the bell mouth filter screen cone surface 13 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com