Injecting decreasing recycling method for water produced in gas field

A technology for producing water and gas fields, which is applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve the problems of reducing the amount of wastewater reinjection, improve the effect of organic matter removal, improve treatment efficiency, and ensure production The effect of water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

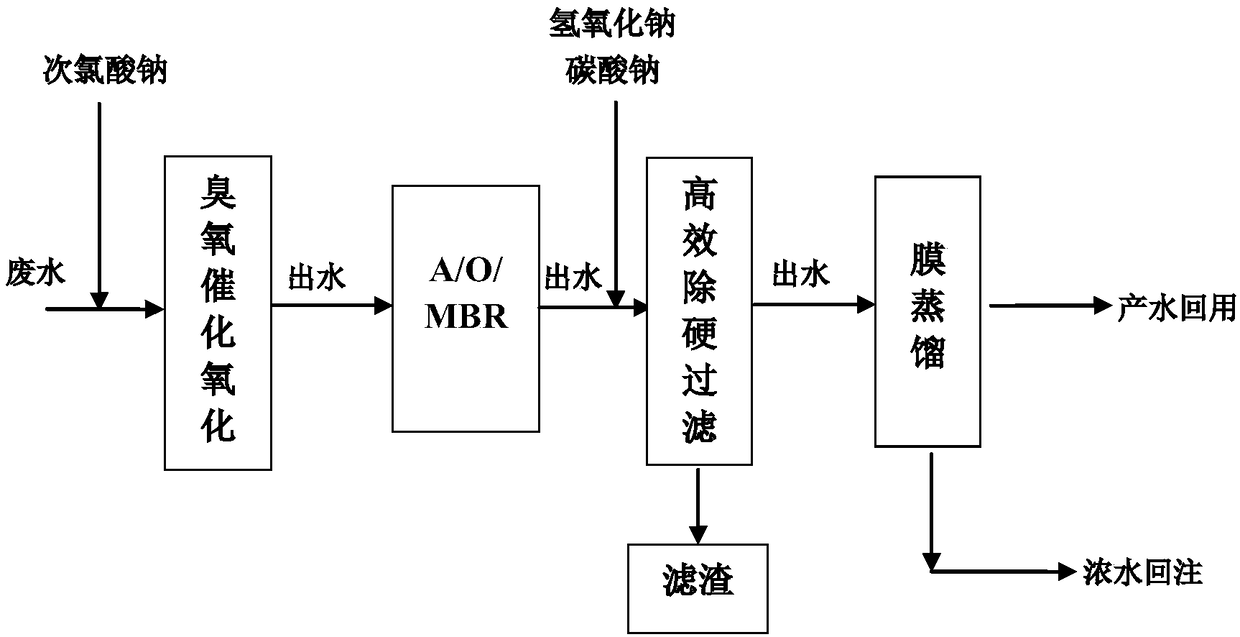

Method used

Image

Examples

Embodiment 1

[0057] The main water quality characteristics of the produced water of a certain gas field are: influent pH 7, total dissolved solids 23000mg / L, suspended solids 300mg / L, oil content 5mg / L, ammonia nitrogen 50mg / L, according to CaCO 3 The total hardness is 800mg / L, according to CaCO 3 Total alkalinity 250mg / L, Na + 4000mg / L, Cl - 5000mg / L, SO 4 2- 800mg / L, COD 1500mg / L.

[0058] The processing steps are as follows:

[0059] Step 1, the gas field produced water enters the ozone catalytic oxidation unit to form ozone catalytic oxidation effluent; the influent pH is 7, the residence time is 1h, and the ozone concentration is 125mg / L;

[0060] Under these conditions, the dosage of ozone is 800mg / L; the COD in the ozone catalytic oxidation water is about 700mg / L, and the ammonia nitrogen is about 47mg / L;

[0061] Step 2: Ozone catalytic oxidation effluent enters the A / O / MBR unit to form MBR product water. Among them, the residence time of the anoxic section A is 4h, the tota...

Embodiment 2

[0069] The main water quality characteristics of the produced water of a certain gas field are: influent pH 7.5, total dissolved solids 30000mg / L, suspended solids 700mg / L, oil content 10mg / L, ammonia nitrogen 120mg / L, according to CaCO 3 The total hardness is 1200mg / L, according to CaCO 3 Total alkalinity 500mg / L, Na + 7000mg / L, Cl - 9000mg / L, SO 4 2- 1100mg / L, COD 2200mg / L.

[0070] The processing steps are as follows:

[0071] Step 1. Before the produced water from the gas field enters the ozone catalytic oxidation unit, set up a pipeline dosing pump and add sodium hypochlorite to remove the remaining small amount of ammonia nitrogen in the wastewater. After dosing, the effluent enters the ozone catalytic oxidation unit to form ozone catalytic oxidation effluent; the influent pH is 7.5, the residence time is 1.5h, and the ozone concentration is 130mg / L;

[0072] Under these conditions, the dosage of ozone is 1200mg / L; the COD in the ozone catalytic oxidation water is ...

Embodiment 3

[0081] The main water quality characteristics of gas field produced water are: influent pH 8, total dissolved solids 35000mg / L, suspended solids 1500mg / L, oil content 20mg / L, ammonia nitrogen 250mg / L, according to CaCO 3 The total hardness is 1800mg / L, according to CaCO 3 Total alkalinity 750mg / L, Na + 10000mg / L, Cl - 12000mg / L, SO 4 2- 1500mg / L, COD 3000mg / L.

[0082] The processing steps are as follows:

[0083] Step 1. Before the produced water from the gas field enters the ozone catalytic oxidation unit, set up a pipeline dosing pump and add sodium hypochlorite to remove the remaining small amount of ammonia nitrogen in the wastewater. After dosing, the effluent enters the ozone catalytic oxidation unit to form ozone catalytic oxidation effluent; the influent pH is 8, the residence time is 2h, and the ozone concentration is 135mg / L;

[0084] Under these conditions, the dosage of ozone is 1500mg / L; the COD in the ozone catalytic oxidation water is about 1050mg / L, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com