Drying method and apparatus for lithium hexafluorophosphate

A technology of lithium hexafluorophosphate and drying equipment, which is applied in the field of lithium ion batteries, can solve the problems of HF cannot be effectively and quickly removed, the drying time of crystals is long, and the quality of products is affected. The effect of the content of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

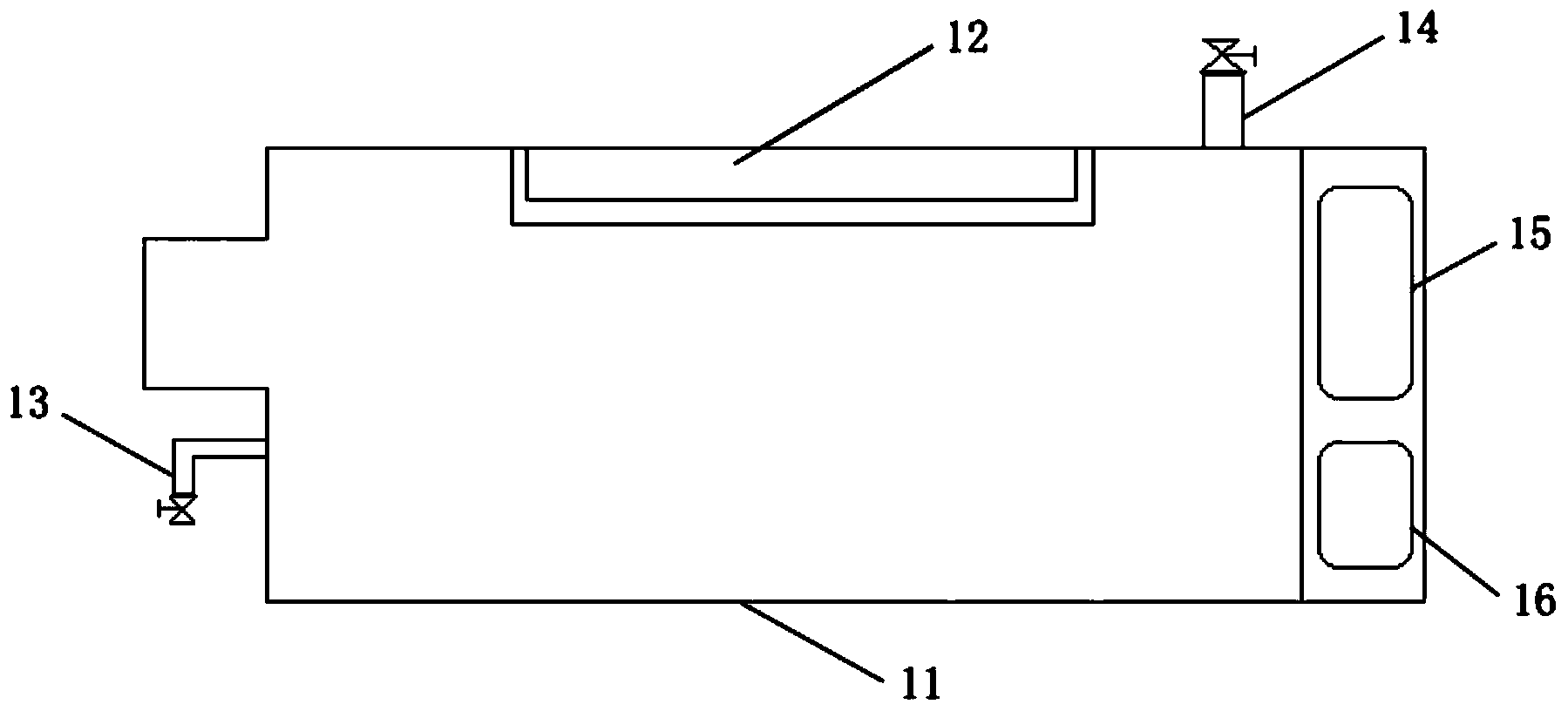

[0027] The drying method of lithium hexafluorophosphate in this embodiment includes the following steps: opening the inert gas inlet 13 and the exhaust gas outlet 14, feeding nitrogen from the inert gas inlet 13 for protection, and placing the lithium hexafluorophosphate to be dried in a dispersed state in the box 11 of the lithium hexafluorophosphate drying equipment , the thickness of the lithium hexafluorophosphate material layer is 10mm, the microwave generator 12 is turned on, the microwave controller 15 is adjusted to make the microwave frequency 865MHz, and the temperature monitoring and control device 16 is used to keep the temperature in the box 11 at 30 ℃, and the microwave radiation process contains HF waste gas Through the exhaust gas outlet 14, the duration of microwave irradiation was 60 minutes.

[0028] The schematic structural diagram of the lithium hexafluorophosphate drying equipment in this embodiment is as follows figure 1 As shown, it includes a sealable ...

Embodiment 2

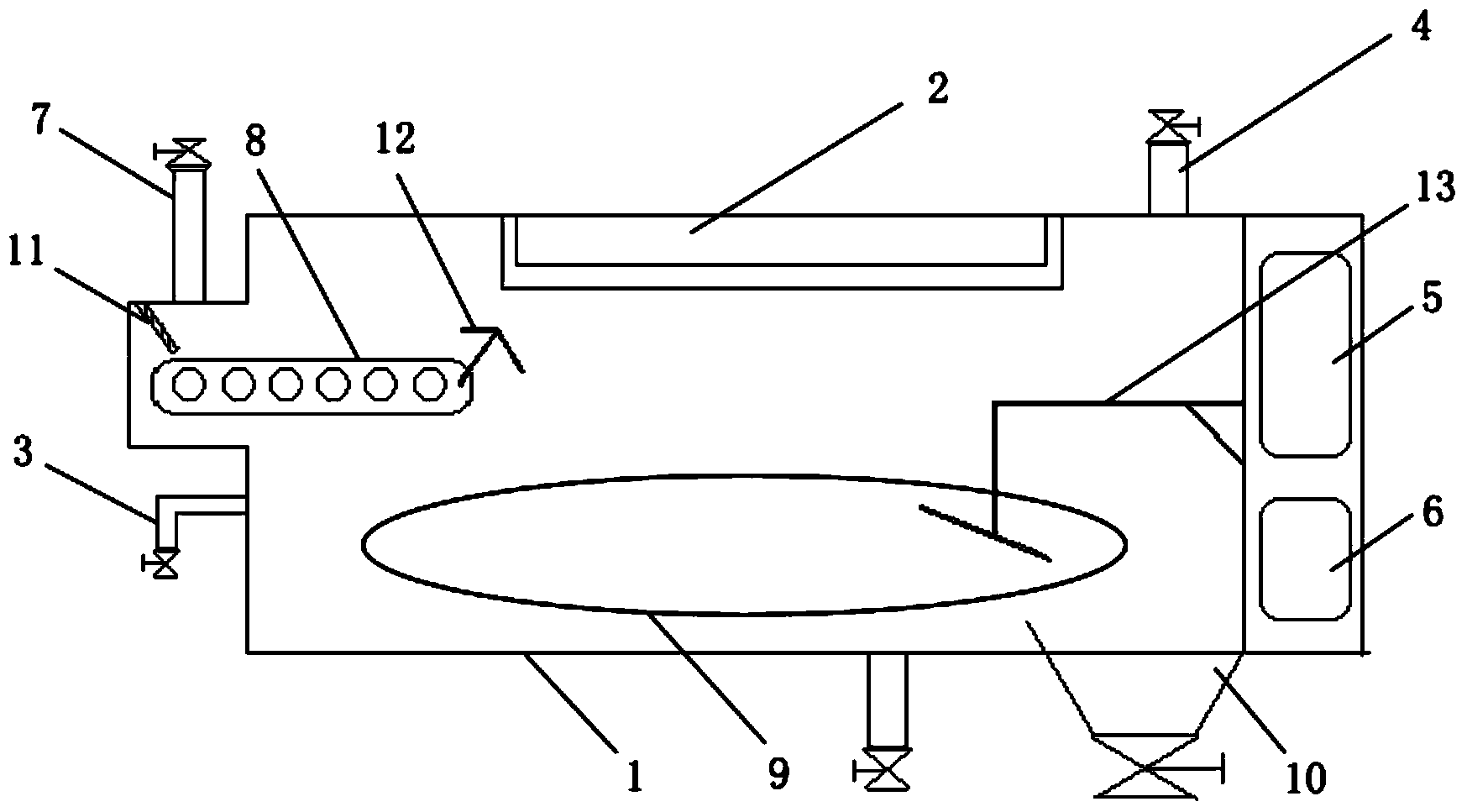

[0032] The drying method of lithium hexafluorophosphate in this embodiment includes the following steps: firstly open the inert gas inlet 3 and the waste gas outlet 4, pass nitrogen from the inert gas inlet 3 for protection, then open the feed port 7, and add the lithium hexafluorophosphate to be dried from the feed port 7. , the drive motor drives the conveyor belt 8 to transfer the lithium hexafluorophosphate to be dried to the loading table 9 that rotates along the axis, and the scraper 13 evenly disperses the lithium hexafluorophosphate to be dried on the loading table 9, so that the thickness of the material layer is 25mm, open The microwave generator 2 uses the microwave controller 5 and the temperature monitoring and control device 6 to adjust the microwave frequency to 915MHz, and keeps the temperature in the box 1 at 70°C. During the microwave radiation process, the HF-containing waste gas is exported through the waste gas outlet 4, and the microwave radiation continues...

Embodiment 3

[0037] The drying method of lithium hexafluorophosphate in this embodiment includes the following steps: firstly open the inert gas inlet 3 and the waste gas outlet 4, pass nitrogen from the inert gas inlet 3 for protection, then open the feed port 7, and add the lithium hexafluorophosphate to be dried from the feed port 7. , the drive motor drives the conveyor belt 8 to transfer the lithium hexafluorophosphate to be dried to the loading table 9 that rotates along the axis, and the scraper 13 evenly disperses the lithium hexafluorophosphate to be dried on the loading table 9, so that the thickness of the material layer is 20mm, open The microwave generator 2 uses the microwave controller 5 and the temperature monitoring and control device 6 to adjust the microwave frequency to 965MHz, and keeps the temperature in the box 1 at 50°C. During the microwave radiation process, the waste gas containing HF is exported through the waste gas outlet 4, and the microwave radiation continues...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com