Heat preservation method for welding spots in welding process of steel pipe

A technology for steel pipes and solder joints, applied in the field of argon arc welding machines, which can solve problems such as reduced strength, reduced stability of steel pipes, and de-welding of steel pipe welds, and achieves the effects of protecting blades, prolonging service life, and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

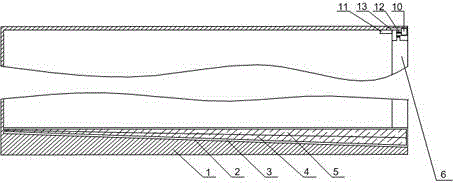

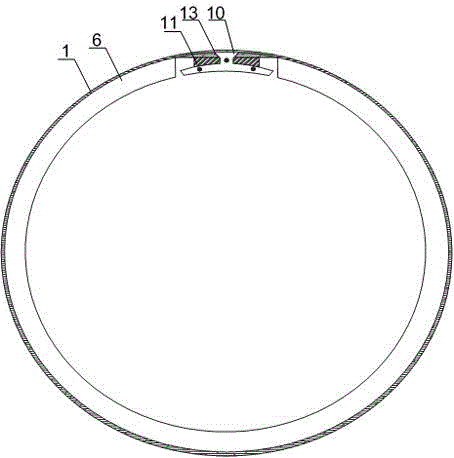

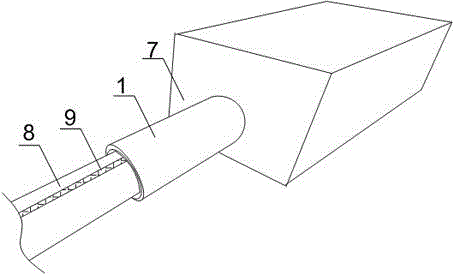

[0023] Such as figure 1 , figure 2 and image 3 As shown, the method for heat preservation of solder joints during steel pipe welding of the present invention includes the following steps. First, the welded steel pipe 8 is sent out from the outlet of the semi-sealed structure 7, and directly enters the sleeve 1, and the cleaning mechanism is facing the steel pipe 8. At the 9 welds, since the temperature of the 9 welds of the steel pipe 8 is relatively high, the function of the sleeve 1 is to provide an environmental condition that can gradually cool down the welded steel pipe 8 at the 9 welds, and at the same time remove the raised bulge caused by welding. Or the residual solder is removed to avoid sudden changes in temperature from affecting the strength of the weld and to ensure the smoothness of the outer surface of the steel pipe 8 after welding; The diameter of the layer 2 decreases radially along the direction of the other end of the sleeve 1, so that the parts of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com