Sheet metal incremental forming device with hydraulic support and auxiliary heating and forming method thereof

A technology of auxiliary heating and hydraulic support, applied in the field of sheet metal incremental forming processing, can solve the problem of uneven deformation of sheet metal, and achieve the effect of solving uneven heating, improving material forming limit, and improving insufficient precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

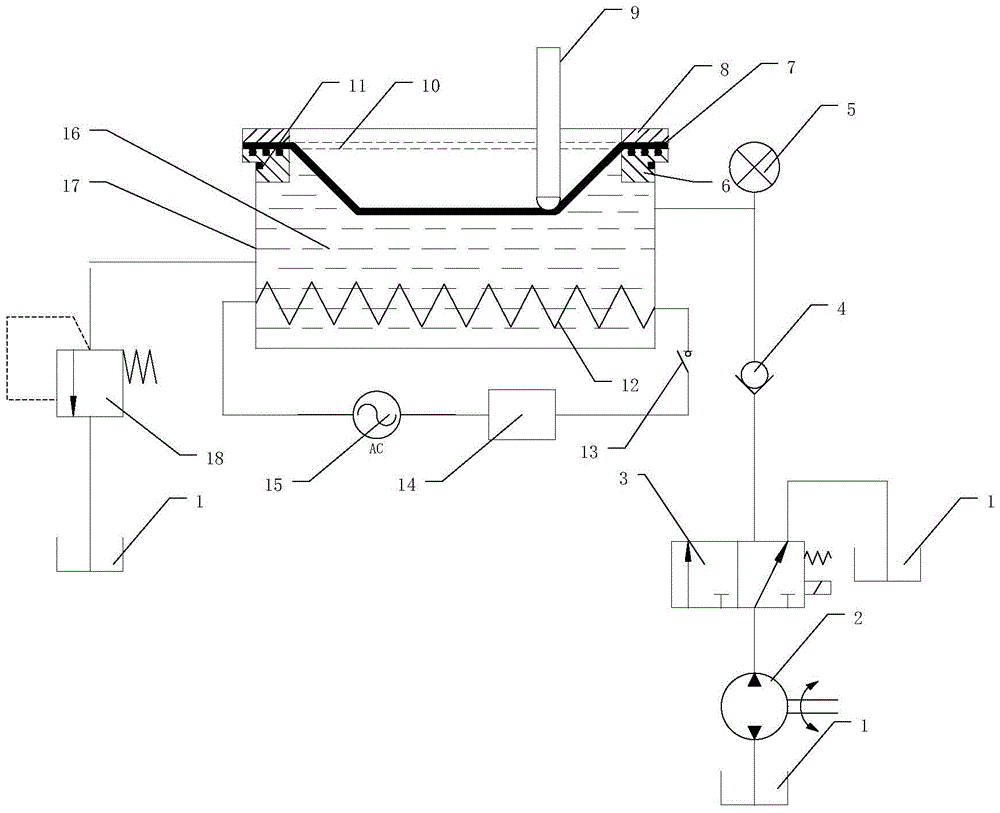

[0046] as attached figure 1 As shown, in the sheet metal progressive forming device with hydraulic support and auxiliary heating:

[0047]The sheet metal forming jig (lower) 6 and the sheet material forming jig (upper) 8 are fixed on the edge of the opening of the box body 17, and the upper and lower sheet metal forming jigs are engaged to fix and clamp the sheet to be formed (undeformed ) 10 edge, the contact between the lower plate forming fixture and the edge of the container opening is sealed by a sealing element 11 to prevent liquid leakage. The liquid (hydraulic oil) in the box body 17 needs to be kept within the set pressure and temperature range according to the specific forming needs. The pressure control system is composed of various hydraulic components to ensure the hydraulic pressure in the box body 17. Through the temperature control circ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com