An electromagnetic pump type double wave crest generator

A technology of wave generator and electromagnetic pump, which is applied in the field of electromagnetic pump type double wave crest generator, can solve the problems that are not conducive to replacement, achieve the effects of compact structure, elimination of shadow area, and control of the formation of oxidized slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

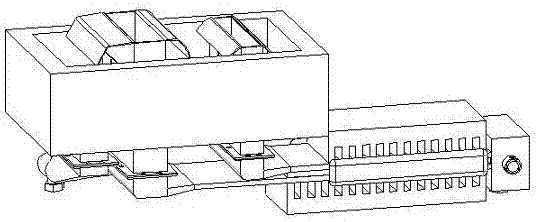

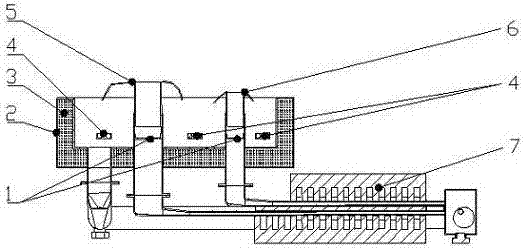

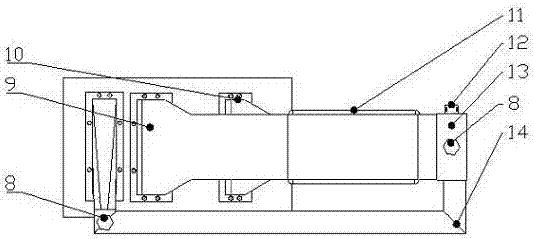

[0025] In the above figures, 1-plug plate, 2-tin pot, 3-insulation asbestos, 4-heating pipe, 5-wide flat wave generator, 6-turbulent wave generator, 7-electromagnetic pump, 8-hexagonal plug , 9-wide flat wave generation pipeline, 10-turbulent wave generation pipeline, 11-crawler heating plate, 12-thermocouple, 13-liquid storage tank, 14-return pipeline, 15-winding, 16-on iron Core, 17-lower iron core, 18-middle iron core, 19-upper pump ditch, 20-lower pump ditch.

[0026]The electromagnetic pump 7 is the core technology of this invention, and consists of an upper iron core 16 wound with a winding 15, an upper pump groove 19, an intermediate iron core 18, a lower iron core 17 wound with a winding 15, and a lower pump groove 20. The structural feature is the quasi-bilateral in-line type, and the iron core is made of silicon steel sheets bonded together. The middle iron core 18 is placed between the upper pump ditch 19 and the lower pump ditch 20, the upper iron core 16 is place...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com