Laser vibrating diaphragm F0 tester

A tester, laser technology, applied in the direction of electrical components, etc., can solve problems such as low precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

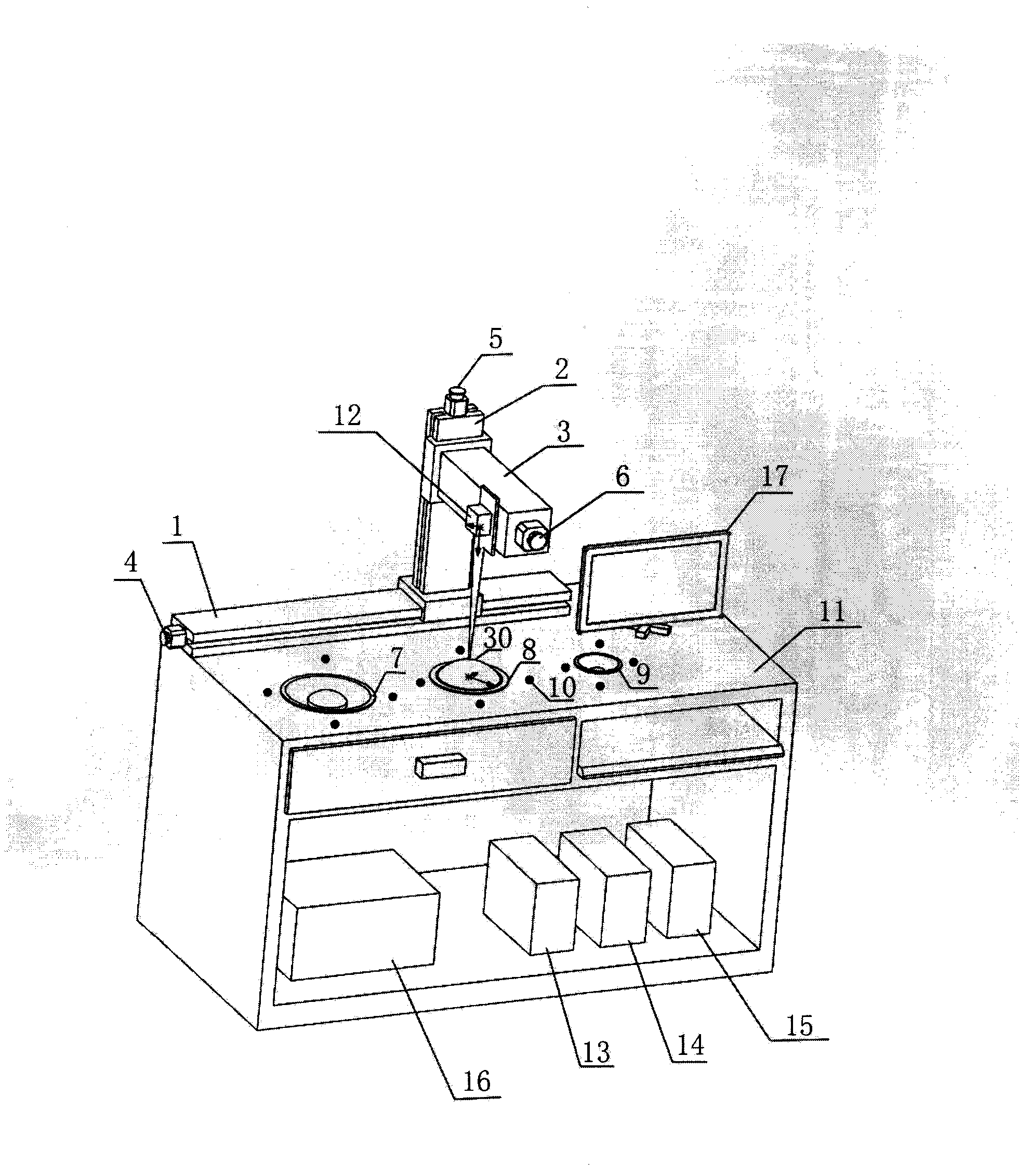

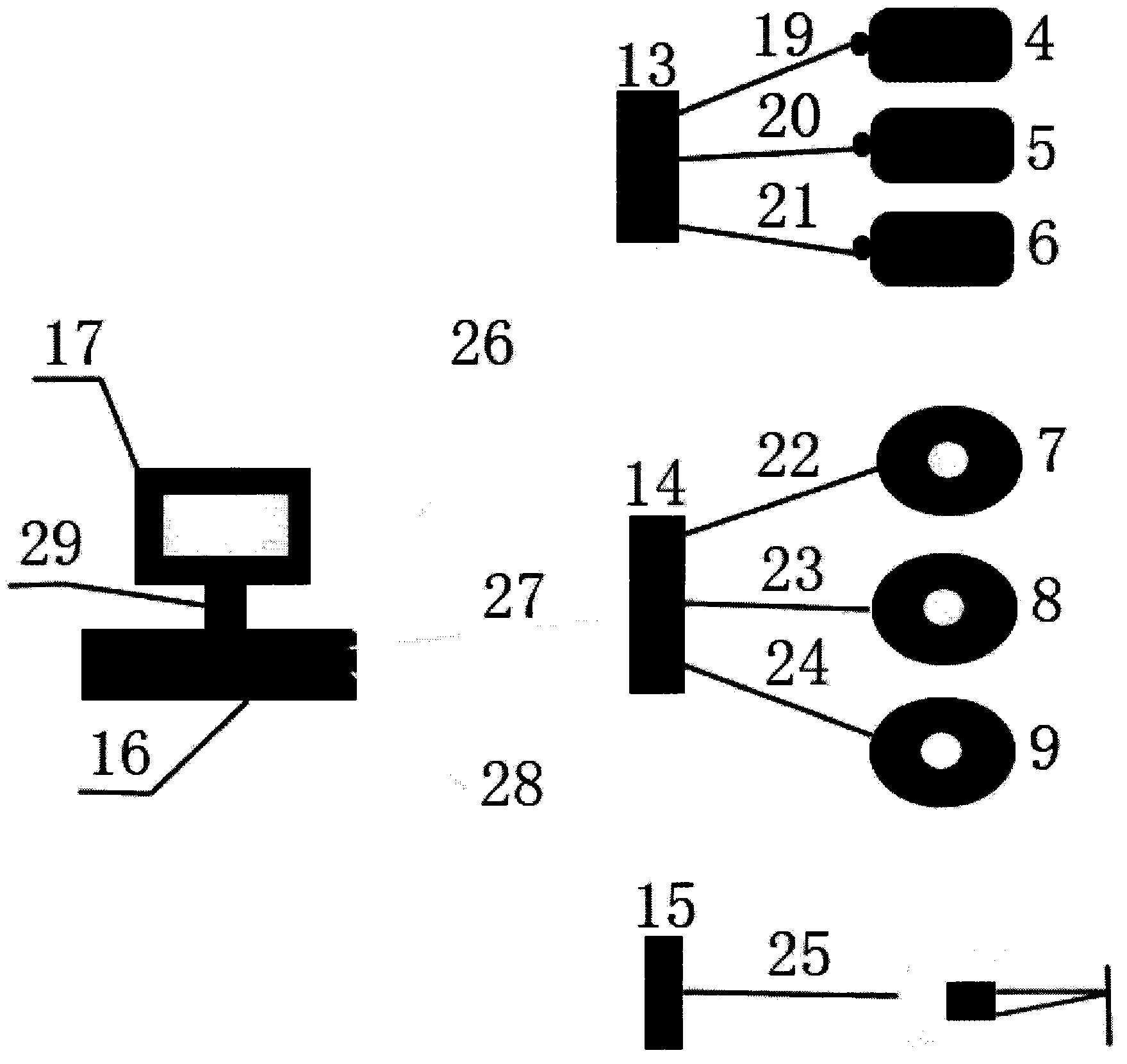

[0011] Such as figure 1 , figure 2 As shown, the laser diaphragm F0 tester of the present invention includes a position determining device, a vibration frequency generating device, a real-time ranging device and a data processing control device.

[0012] The position determining device is used to move the laser displacement sensor 12 to the best measurement position, and it includes the X-axis guide rail 1 and its servo motor 4, the Y-axis guide rail 2 and its servo motor 5, and the Z-axis guide rail 3 and its servo motor 6 , A three-axis closed-loop console 13, the servo motor 4 is connected to a three-axis closed-loop console 13 through a line 19, the servo motor 5 is connected to a three-axis closed-loop console 13 through a line 20, and the servo motor 6 is connected through a line 21 Connected to the three-axis closed-loop console 13.

[0013] The vibration frequency generating device is used to drive the tested diaphragm 30 to vibrate. It includes an audio power amplifier 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com