Novel waterproof SMD (surface mounted device) LED and production technology thereof

A production process and patch technology, which is applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problems of water vapor and other impurities intrusion, water vapor intrusion, water seepage of LED packaging adhesive layer, etc., and achieve low cost and high reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

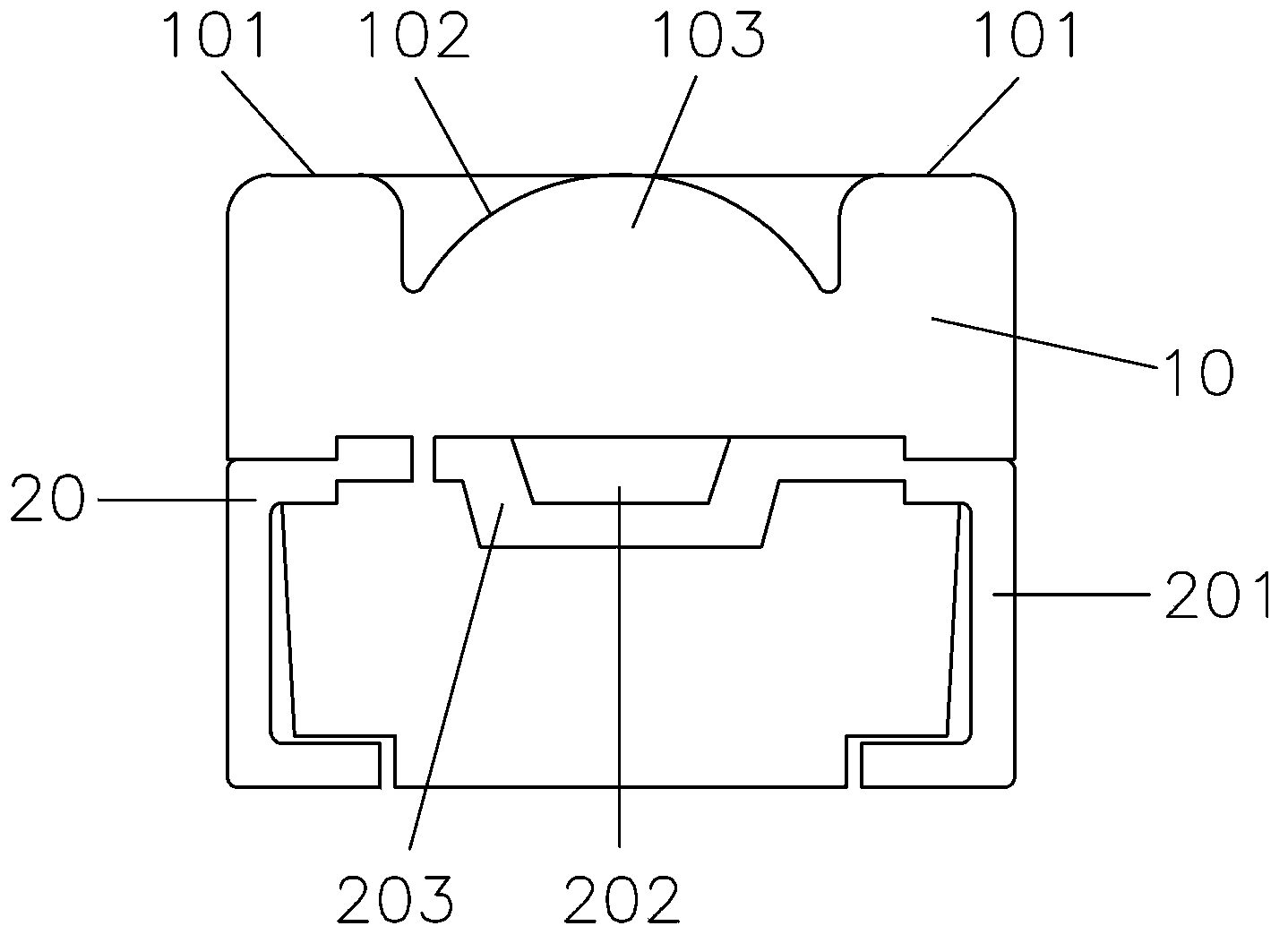

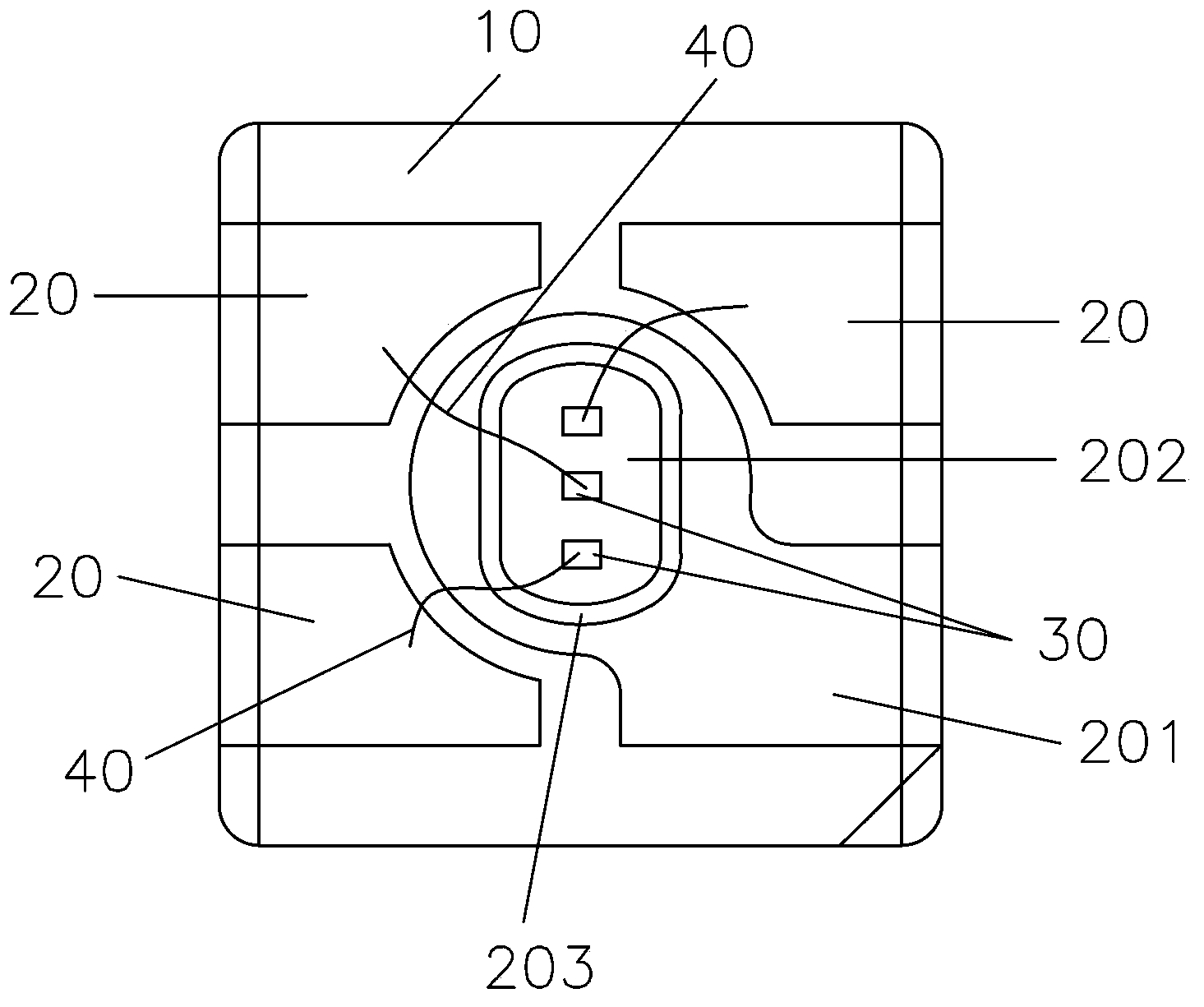

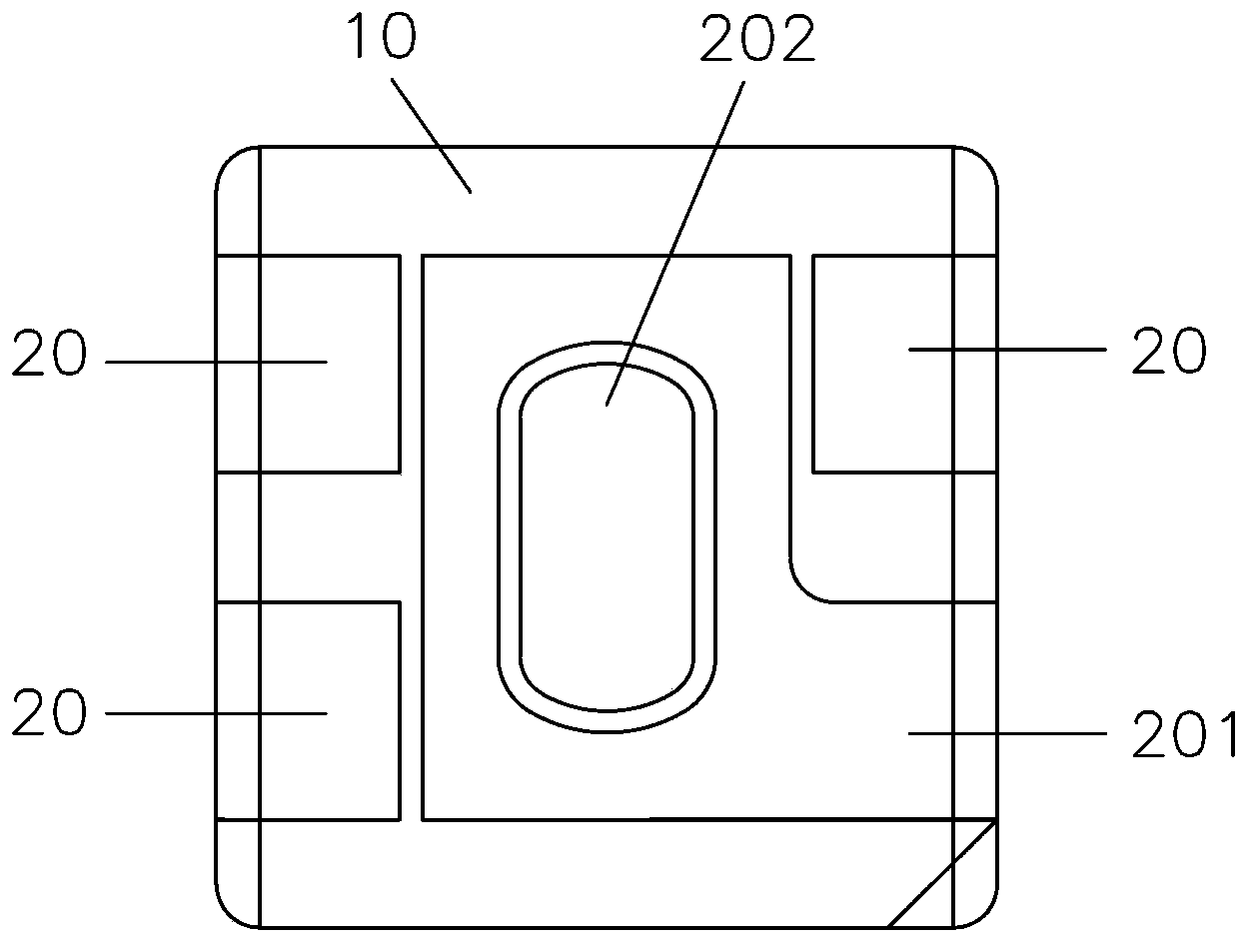

[0034] refer to figure 1 , figure 2 As shown, the present invention discloses a novel waterproof SMD LED, which includes an epoxy resin encapsulation body 10, and at least two brackets 20 with one end extending into the interior of the epoxy resin encapsulation body 10, and in this embodiment For example, refer to figure 2 As shown, four brackets 20 are provided, and one of the brackets 201 of the four brackets 20 is provided with a crystal-fixing area 202. Generally, the bracket 201 is provided with a frustum-shaped bowl 203, and the bottom of the bowl 203 is is the crystal-bonding area 202, and the bracket 201 is the common end bracket, figure 1 Among them, after the protruding ends of the four brackets are bent, they are folded back and buckled to the bottom of the epoxy resin package body 10 . refer to figure 2 As shown, three LED chips 30 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com