Torque motor-based diamond cutting disc performance testing device and method

A diamond cutting and torque motor technology, which is used in testing wear resistance, testing machinability, etc., can solve the non-constant force state of the cutting blade, and cannot more accurately test the sharpness, durability and service life of the diamond cutting blade performance, difficulty in simulating the working state of the cutting blade, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

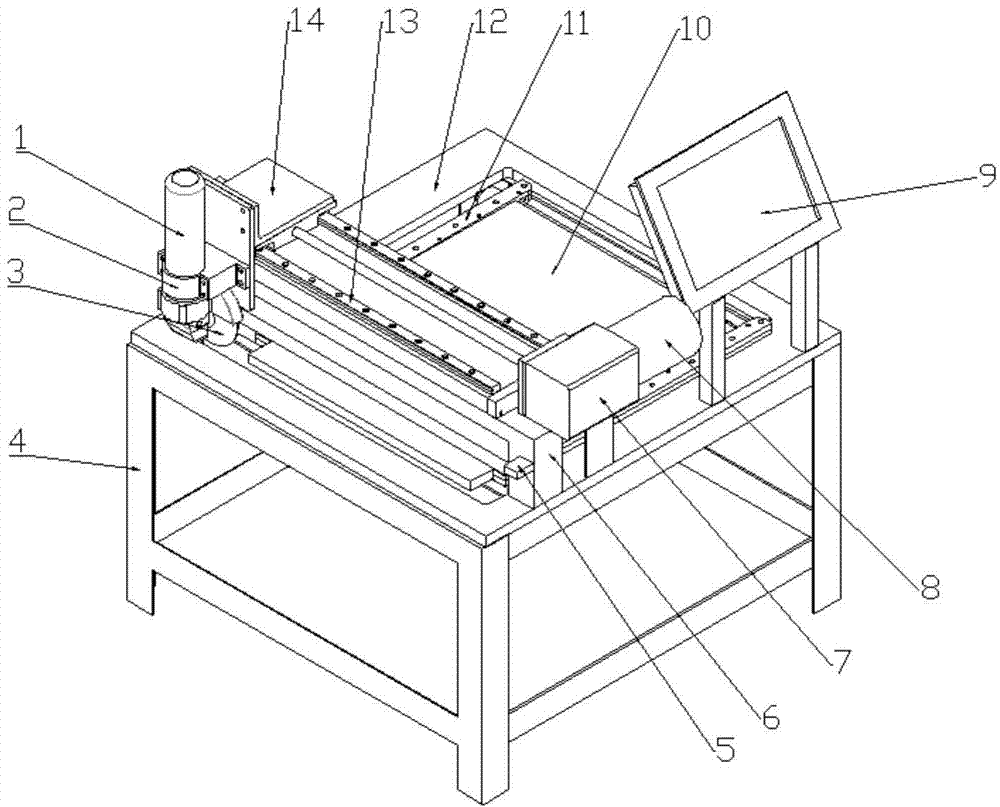

[0027] see figure 1 , the present embodiment is provided with angle grinder 1, angle grinder fixing frame 2, diamond cutting blade 3, device fixing frame 4, diamond cutting blade outer diameter detector 5, precision rail fixing frame 6, torque motor 7, code disc 8 , computer controller 9, Dali board material 10, Dali board material fixing frame 11, device platform 12, precision guide rail 13 and angle grinder motion slider frame 14.

[0028] Angle grinder 1, torque motor 7 and code disc 8 are controlled by computer controller 9. The angle grinder 1 is fixed on the angle grinder moving slider frame 14 through the angle grinder fixing frame 2, and the angle grinder moving slider frame 14 is cross-shaped so that the angle grinder 1 can be placed vertically, ( figure 1 The angle grinder 1 is shown in its initial state). The precision guide rail 13 is flatly fixed on the precision guide rail fixing frame 6, the output shaft of the torque motor 7 is connected with the lead screw o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com