A method for battery critical failure detection

A detection method and battery technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of UPS not working, catastrophic, battery failure, etc., to achieve the effect of convenient sorting and comparison, and avoiding too long charging time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

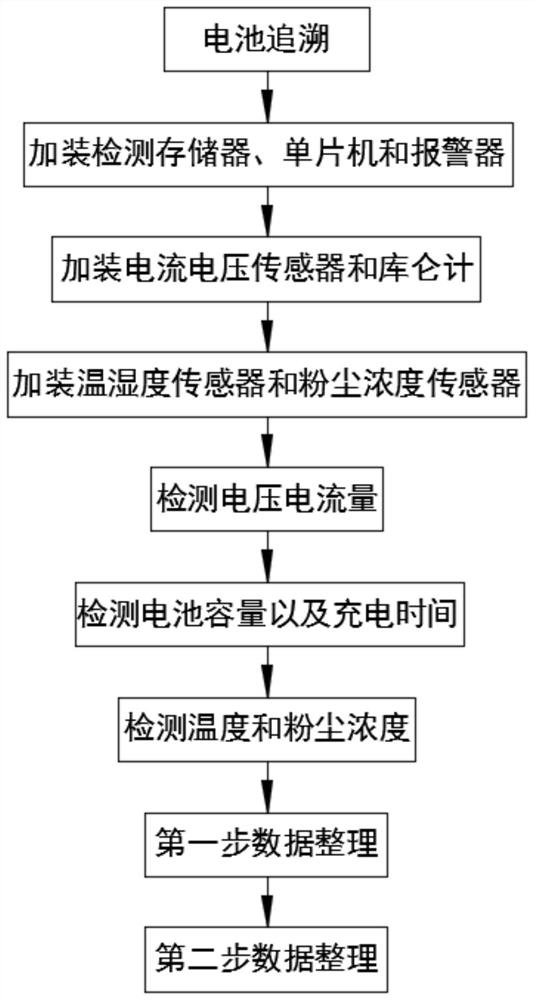

[0025] The present invention provides such figure 1 A battery critical failure detection method is shown, and the detection method is as follows:

[0026] Step 1: Battery traceability. Before the battery is assembled in the UPS, its manufacturer, production time, battery performance parameters and service life are traced through the battery QR code, and these data are stored in the memory;

[0027] Step 2: Install detection memory, single-chip microcomputer and alarm, respectively install the memory, single-chip microcomputer, alarm and wireless communication module in the UPS, and use them synchronously with the battery, and the single-chip microcomputer communicates with the CPU controller inside the UPS and the UPS through the wireless communication module remote device connection;

[0028] Step 3: Install a current and voltage sensor and a coulomb counter, and connect the charging and discharging cables of the battery to the current and voltage sensor. The current and vol...

Embodiment 2

[0036] In step seven, the temperature and dust concentration are detected. When the battery is charging and discharging, the temperature and humidity sensor and the dust concentration sensor can detect the ambient temperature and dust concentration of the battery, the charging connection line, the discharge connection line, and the UPS, and the temperature and humidity sensor And the dust concentration sensor converts the signal into a digital signal through the A / D converter and sends it to the single-chip microcomputer. The single-chip microcomputer sends the signal to the remote device for data processing and detection, and compares the surrounding temperature of the battery, charging connection line and discharge connection line with the temperature inside the UPS. In contrast, when the dust concentration is high, the temperature rises everywhere is greater than the set value, and the voltage and current detection values are normal, that is, the battery surface has poor he...

Embodiment 3

[0038]In step seven, the temperature and dust concentration are detected. When the battery is charging and discharging, the temperature and humidity sensor and the dust concentration sensor can detect the ambient temperature and dust concentration of the battery, the charging connection line, the discharge connection line, and the UPS, and the temperature and humidity sensor And the dust concentration sensor converts the signal into a digital signal through the A / D converter and sends it to the single-chip microcomputer. The single-chip microcomputer sends the signal to the remote device for data processing and detection, and compares the surrounding temperature of the battery, charging connection line and discharge connection line with the temperature inside the UPS. In contrast, when the temperature of a single location rises too high, it may be that the wiring is loose (poor contact, line aging), and timely maintenance is required;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com