Wireless passive rope tension sensor based on surface acoustic waves

A surface acoustic wave, wireless passive technology, applied in the field of sensors, can solve the problems of the active surface acoustic wave sensor having no particular advantages, external influences cannot be measured, and no obvious advantages, etc., and achieves good linearity and installation. Convenient and simple, high-sensitivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

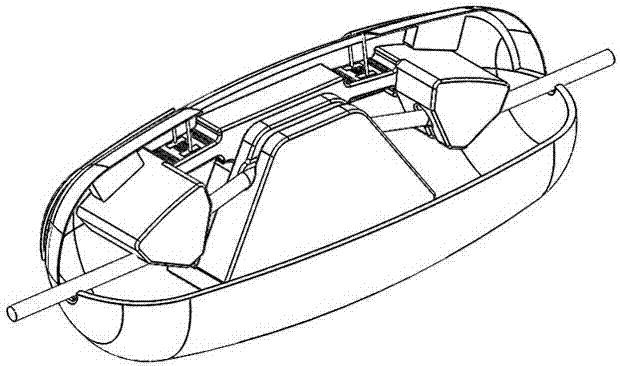

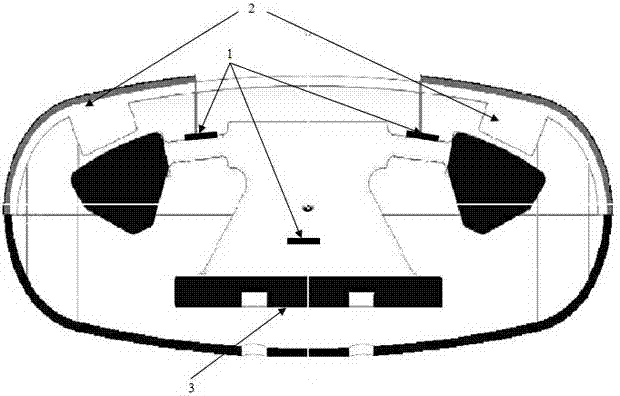

[0044] The invention discloses a wireless passive rope tension sensor based on surface acoustic waves, which comprises a T-shaped force bearing, three surface acoustic wave resonators, a housing and an antenna;

[0045] The shell is elliptical, and both ends are provided with through holes for threading ropes;

[0046] The antenna is arranged on the outer surface of the casing,

[0047] The T-shaped force-bearing seat is fixedly arranged in the housing, and is composed of two force arms and a base. The ends of the two force arms far from the base are each provided with an inverted triangle, and the bottom of the seat is trapezoidal. The body and the upper end are provided with grooves for fixing ropes;

[0048] The lower part of the inverted triangle is provided with a through hole for fixing the rope;

[0049] Two of the three surface acoustic wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com