Digital signal processor (DSP) based linear array charge coupled device (CCD) online detection system for absorbable suture line diameter

A detection system and suture technology, which is applied in the fields of sensors and signal processing, measuring instruments, and medical devices, can solve problems such as influence on the production process, easy deformation, and data processing capabilities that cannot reach high-speed online measurement to achieve uniformity Good, the effect of improving production efficiency and localization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to understand the present invention more clearly, describe the present invention in detail in conjunction with accompanying drawing and embodiment:

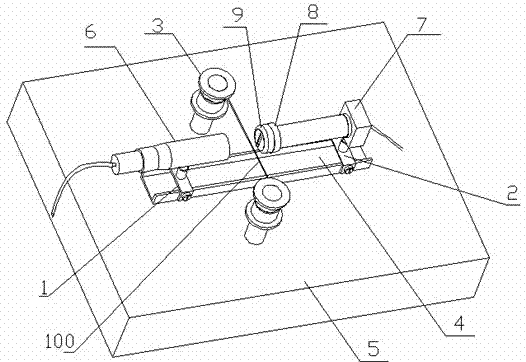

[0054]DSP-based linear array CCD absorbable suture line diameter online detection system, including structural parts and system circuits, structural parts include light source support 1, CCD support 2, guide wheel 3 and guide rail 4; guide wheel 3 and guide rail 4 are wet-spun The platform 5 of the silk machine is a fixed surface, the guide rail 4 is fixed on the middle part of the platform 5, two guide wheels 3 are placed on both sides of the guide rail 4, and the axle 31 of the guide wheel 3 is fixed on the platform 5;

[0055] The light source bracket 1 is a Π-shaped structure, including a horizontal arm A11 and two vertical arms A12 at both ends thereof. The length of the arm of the horizontal arm A11 matches the width of the guide rail 4. The width of the guide rail 4, the inner surface of the two vertical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com