A new ultra-high temperature cage type ram and its processing technology

A processing technology and ultra-high temperature technology, applied in the field of new ultra-high temperature cage gate and its processing technology, can solve the problems affecting the waste heat power generation system and the inability to realize the adjustment or opening and closing functions of ultra-high temperature gate valves, so as to reduce the Overall thermal deformation, reduced risk of being stuck, and good creep resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0031] Hereinafter, the present invention will be further described in detail through specific embodiments in conjunction with the drawings.

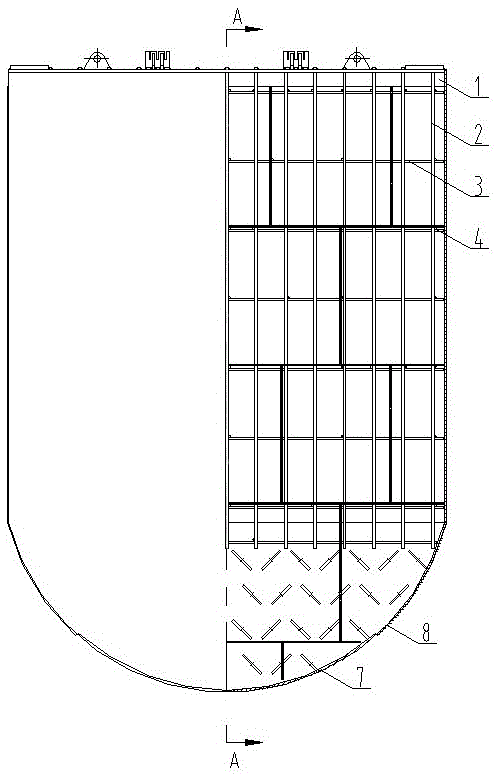

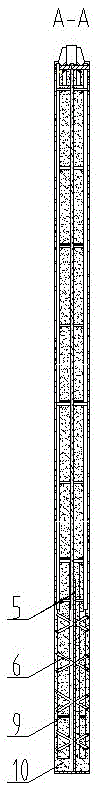

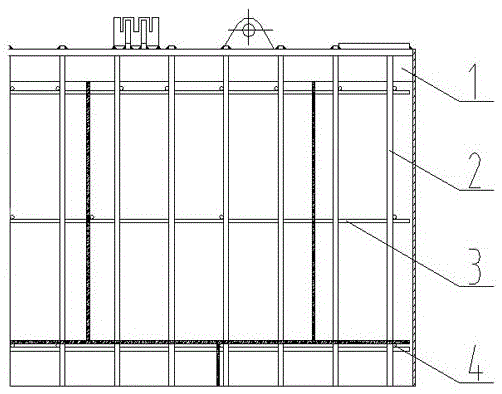

[0032] Please refer to Figure 1 ~ Figure 6 , The new type of ultra-high temperature net cage gate in the embodiment of the present invention is different in that: the plate body includes the main beam 1, the longitudinal rib 2, the transverse rib 3, the vertical rib 4, the lining plate 5, and the guard plate 7. The upper part of the plate body is a rectangular net cage structure, and the lower part is a semicircular structure. The main beam 1 on the upper part of the plate body is symmetrically welded with multiple sets of longitudinal ribs 2 arranged in the vertical direction. Set the horizontal ribs 3 arranged in the horizontal direction. At the intersection of the longitudinal ribs 2 and the horizontal ribs 3, there are vertical ribs 4 for supporting and strengthening. The lower part of the plate body is provided with a semicircular li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com