System and method for cleaning spinneret orifices of spinneret plate

A spinneret and spinning hole technology, which is applied in the field of cleaning spinneret spinning hole systems, can solve the problems of inability to complete hole-by-hole inspection, increase the performance of defective products, and reduce the quality of spinning, and achieve simple data interpretation and environmental protection. The effect of limiting low demand and increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

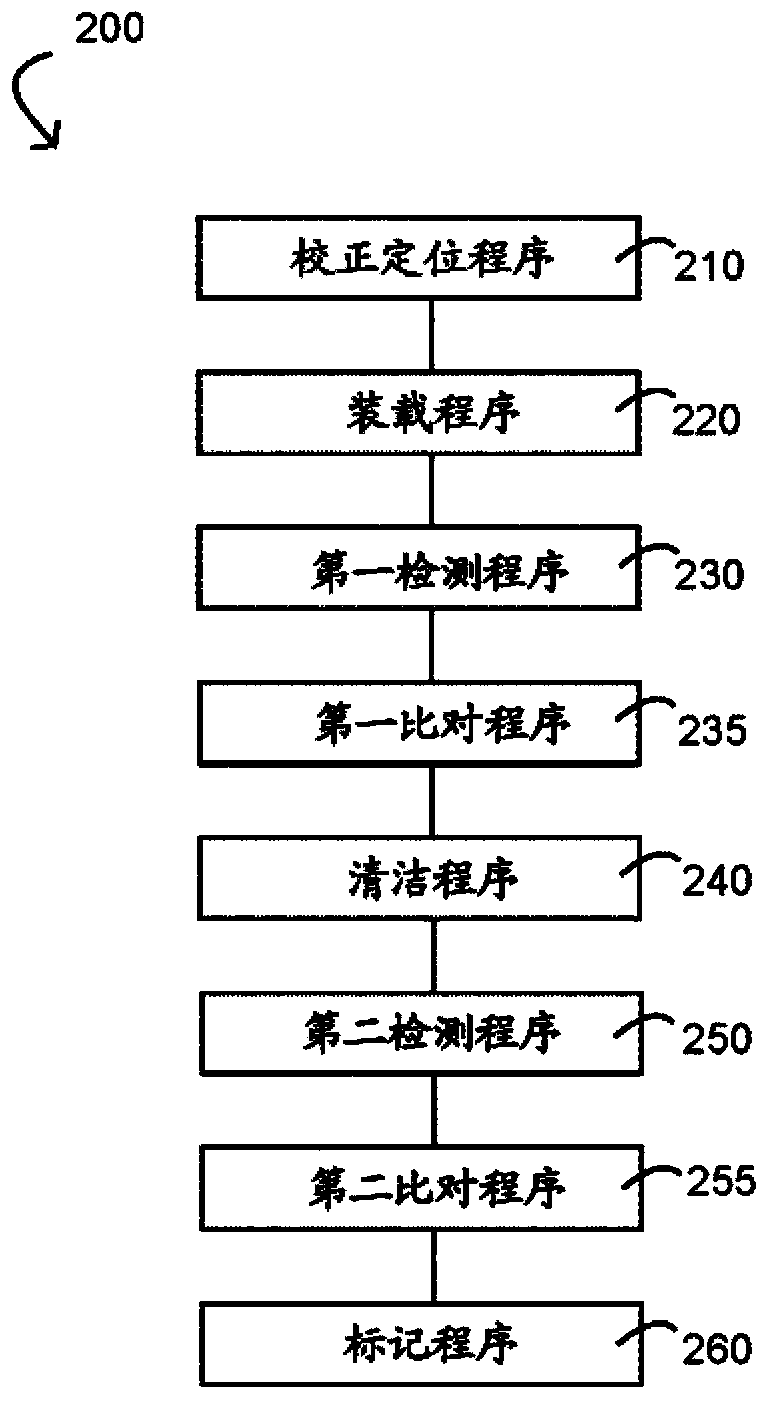

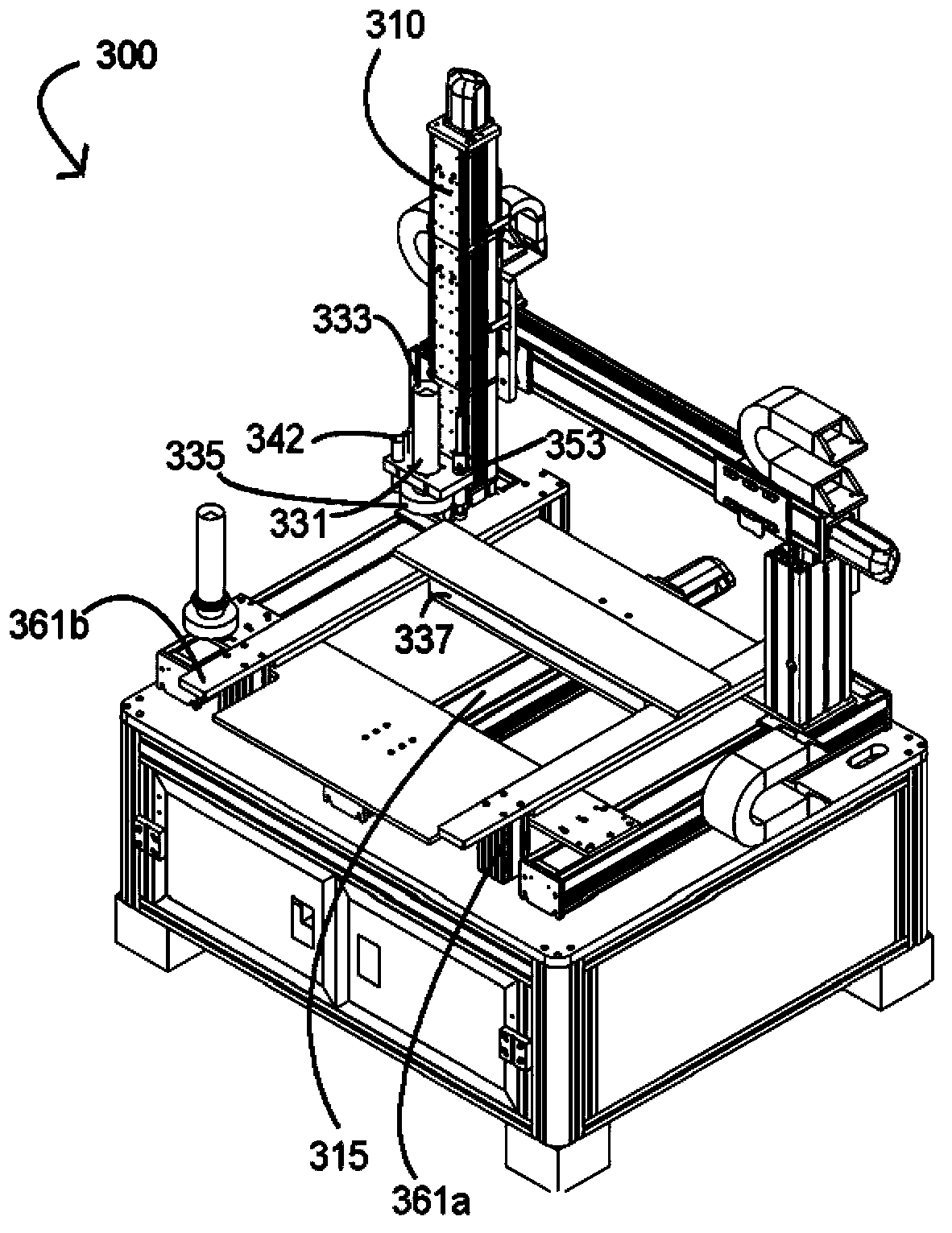

[0066] In order to further explain the technical means and effects that the present invention takes to achieve the intended purpose of the invention, below in conjunction with the accompanying drawings and preferred embodiments, a specific description of a cleaning spinneret spinning hole system and method thereof proposed according to the present invention Embodiments, structures, features and effects thereof are described in detail below.

[0067] The direction of the present invention discussed here is the cleaning technology for cleaning the spinning hole system of the spinneret. In order to thoroughly understand the present invention, the detailed structure and its components and method steps will be provided in the following description. In other instances, well-known structures and elements thereof have not been described in detail in order not to unnecessarily limit the invention. In addition, in order to provide a clearer description and enable those skilled in the ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com