Device and method for preparing anodic aluminum oxide template with large pore diameter

An anodized aluminum, large pore size technology, used in electrolytic coatings, surface reaction electrolytic coatings, coatings, etc., can solve problems such as the inability to independently complete the oxidation process, widen the scope and degree of application, the overall distribution of pores is uniform, The effect of generating a neat and stable rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

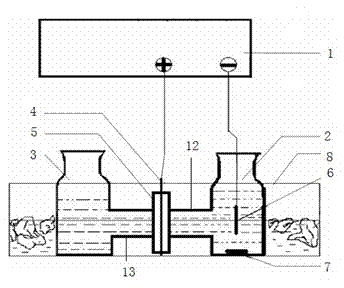

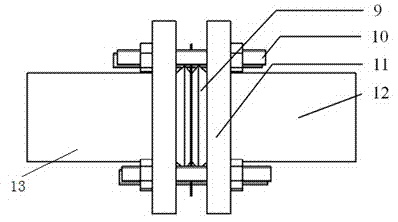

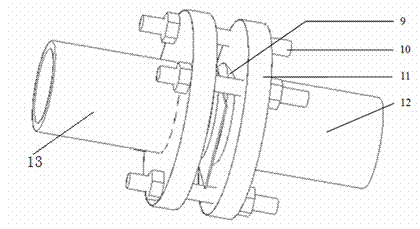

[0041] The device for preparing a highly ordered large-aperture anodic aluminum template described in this embodiment includes a regulated DC power supply 1, a front electrolytic bottle 2, a reverse electrolytic bottle 3, a high-purity aluminum sheet 4, an aluminum sheet clamping kit 5, The high-purity platinum electrode 6, the magnetic stirrer 7, the ice-water bath cooling tank 8, the solution channel I12 of the front electrolytic bottle 2 is locked and connected with the solution channel II13 of the reverse electrolytic bottle 3 through the aluminum sheet clamping kit 5 to form an integrated electrolytic bottle; The high-purity aluminum sheet 4 is vertically clamped in the aluminum sheet clamping set 5, and the high-purity platinum electrode 6 extends into the front electrolytic bottle 2 and is parallel to the high-purity aluminum sheet 4; the high-purity aluminum sheet 4 and the high-purity platinum electrode 6 pass through the wire Connect with the regulated DC power supply...

Embodiment 2

[0053] The device for preparing a highly ordered large-aperture anodic aluminum template described in this embodiment includes a regulated DC power supply 1, a front electrolytic bottle 2, a reverse electrolytic bottle 3, a high-purity aluminum sheet 4, an aluminum sheet clamping kit 5, The high-purity platinum electrode 6, the magnetic stirrer 7, the ice-water bath cooling tank 8, the solution channel I12 of the front electrolytic bottle 2 is locked and connected with the solution channel II13 of the reverse electrolytic bottle 3 through the aluminum sheet clamping kit 5 to form an integrated electrolytic bottle; The high-purity aluminum sheet 4 is vertically clamped in the aluminum sheet clamping set 5, and the high-purity platinum electrode 6 extends into the front electrolytic bottle 2 and is parallel to the high-purity aluminum sheet 4; the high-purity aluminum sheet 4 and the high-purity platinum electrode 6 pass through the wire It is connected to the regulated DC power ...

Embodiment 3

[0065] The device for preparing a highly ordered large-aperture anodic aluminum template described in this embodiment includes a regulated DC power supply 1, a front electrolytic bottle 2, a reverse electrolytic bottle 3, a high-purity aluminum sheet 4, an aluminum sheet clamping kit 5, The high-purity platinum electrode 6, the magnetic stirrer 7, the ice-water bath cooling tank 8, the solution channel I12 of the front electrolytic bottle 2 is locked and connected with the solution channel II13 of the reverse electrolytic bottle 3 through the aluminum sheet clamping kit 5 to form an integrated electrolytic bottle; The high-purity aluminum sheet 4 is vertically clamped in the aluminum sheet clamping set 5, and the high-purity platinum electrode 6 extends into the front electrolytic bottle 2 and is parallel to the high-purity aluminum sheet 4; the high-purity aluminum sheet 4 and the high-purity platinum electrode 6 pass through the wire It is connected to the regulated DC power ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com