Etching paste component and application thereof

A composition and etching paste technology, which is applied in the direction of surface etching composition, electrical components, semiconductor/solid-state device manufacturing, etc., can solve the problems of high corrosiveness, chemical raw material toxicity, time-consuming wet etching method, etc. The effect of good stability of net and viscosity over time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0070] The preparation method of the etching paste composition is to mix the fluorine-containing compound (A), the solvent (B), the particles (C), the organic thickener (D) and the acid (E), and stir for a sufficient time to form a thixotropic Viscous paste in nature. Stirring can be performed at 15 to 35°C or with warming to a suitable temperature.

[0071] The etching method of the present invention comprises:

[0072] Provide a touch panel, including a substrate, and a silicon oxide layer or a silicon nitride layer disposed on the substrate;

[0073] screen printing the etching paste composition as described above on the silicon oxide layer or silicon nitride layer;

[0074] performing an etching step; and

[0075] Proceed to the washing step.

[0076] The material of the substrate is not particularly limited, and general materials are applicable.

[0077] The so-called silicon oxide layer, except pure SiO of glass or quartz 2 Also, all SiO-based 2 system, consisting...

Embodiment 1

[0086] In a 1-liter polypropylene cup, at 15 to 35°C, add 100 parts by weight of ammonium bifluoride (A-1), and 100 parts by weight of (4-isopropylphenyl)methanol (B-1-3) , 100 parts by weight of water (B-2), ethylene glycol (B-3-1) of 300 parts by weight and formic acid (E-1-1) of 30 parts by weight were uniformly stirred for 5 minutes, while stirring Add 300 parts by weight of polytetrafluoroethylene (C-1-1), and stir for 5 minutes, and finally add 10 parts by weight of cellulose (D-1), and stir for 60 minutes at a rotating speed of 500rmp to obtain Example 1 composition of etching paste.

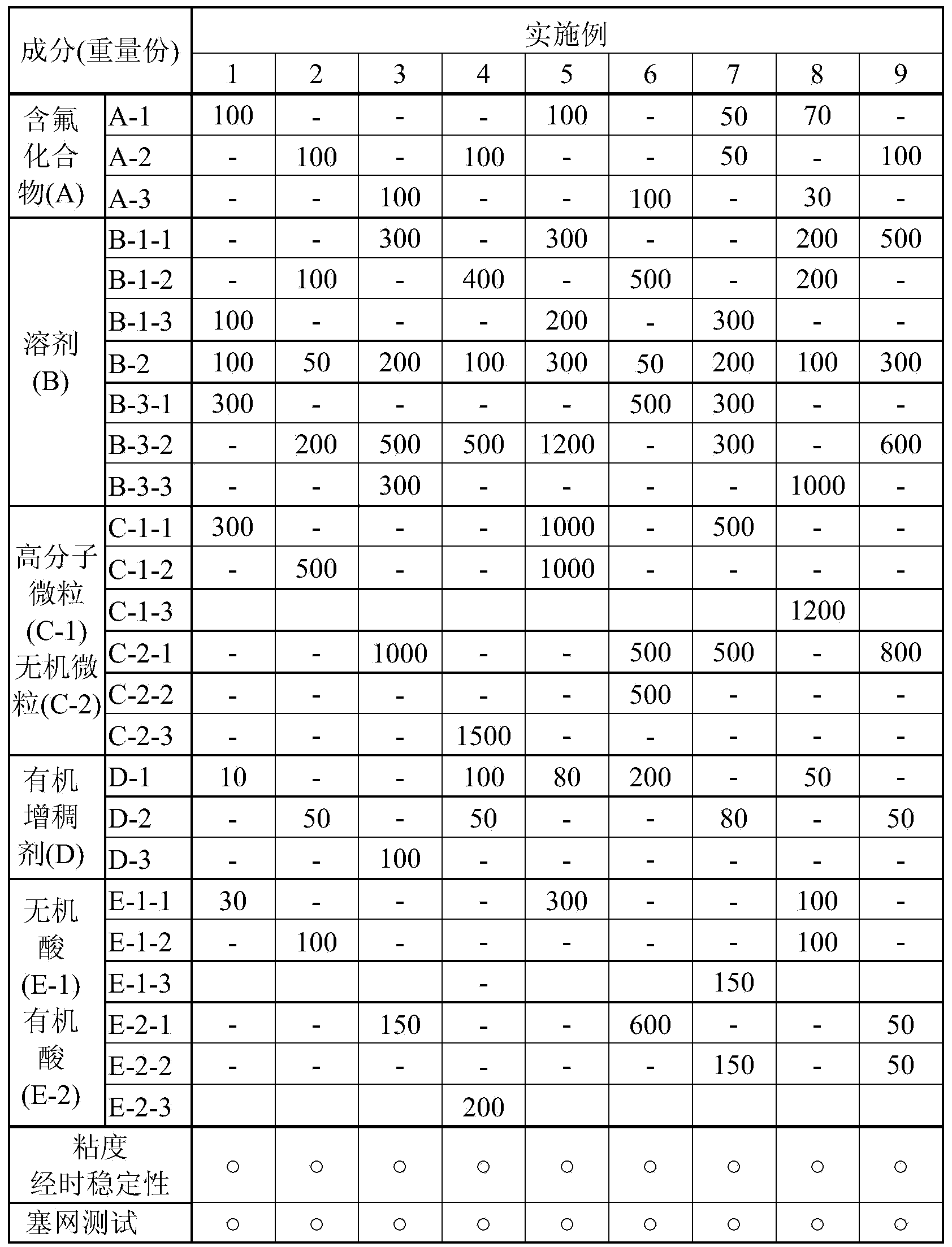

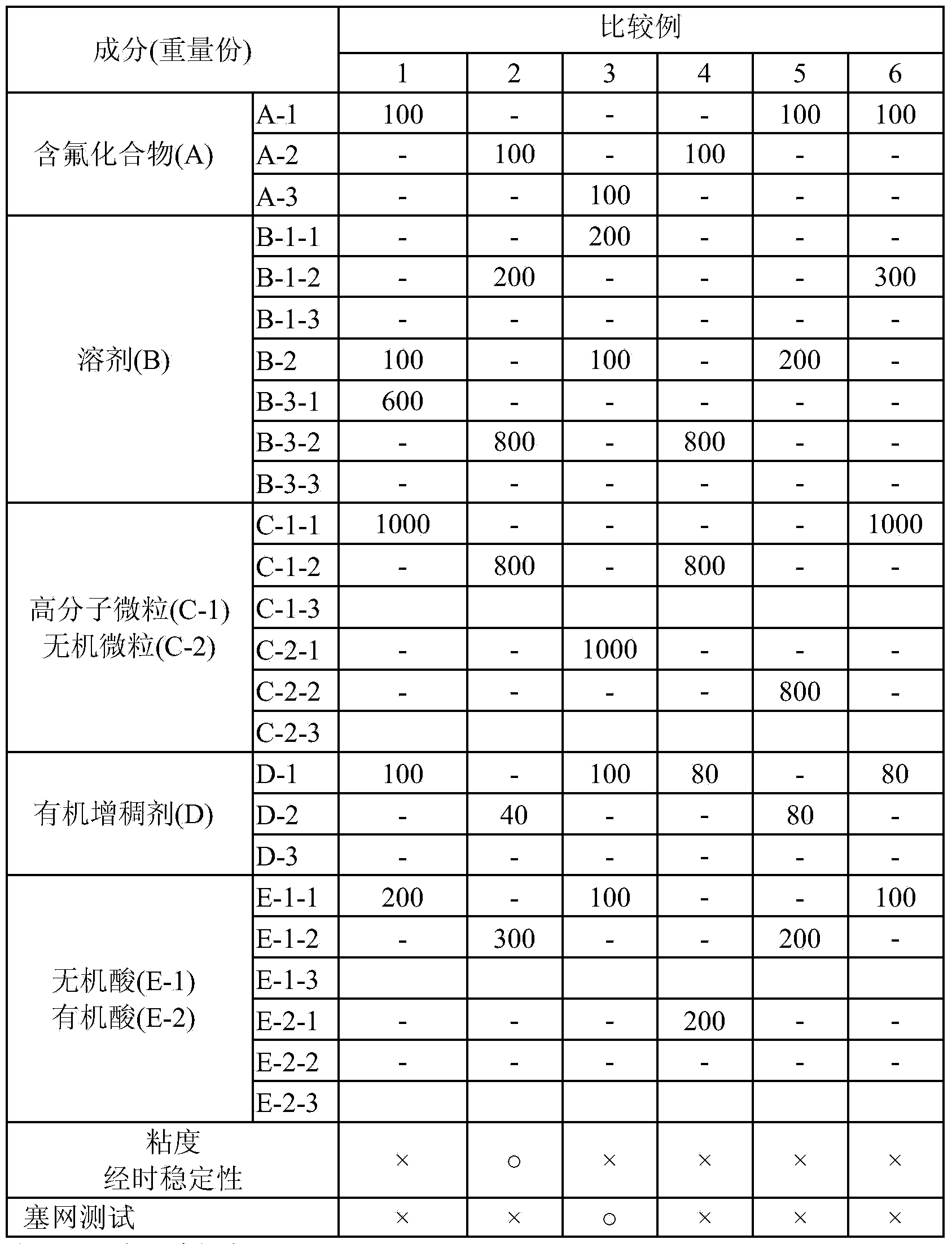

Embodiment 2 to 9 and comparative example 1 to 6

[0088] Embodiment 2 to 9 and comparative example 1 to 6 are to prepare this etching paste composition with the same step as embodiment 1, and difference is: change the kind of chemical and its usage amount, the kind of this chemical and its amount. The amount used is shown in Table 1 and Table 2.

[0089]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com