A kind of energy-saving clean production method of iminodiacetic acid

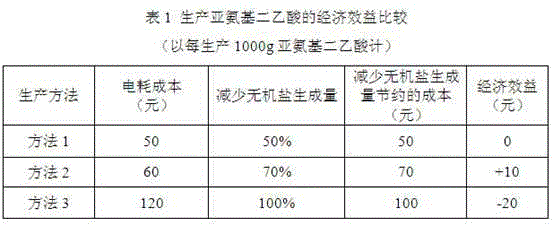

A technology of iminodiacetic acid and iminodiacetic acid disalt is applied in the field of energy-saving and clean production of iminodiacetic acid, which can solve the problems of short conversion time in the early stage, increased demand for membranes, and difficulty in implementation, and reduce the generation of inorganic salts. The effect of saving sulfuric acid and steam, saving production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

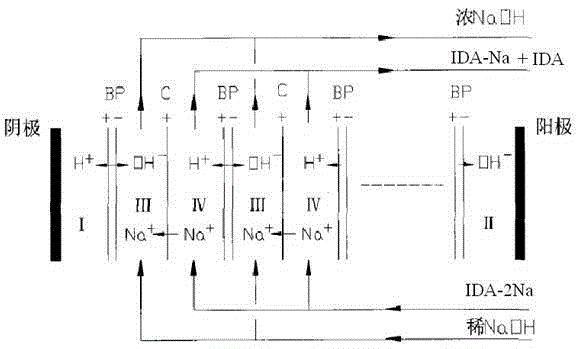

Image

Examples

Embodiment 1

[0034] Preparation of iminodiacetonitrile reaction solution: Add aluminum oxide to hydroxyacetonitrile with a concentration of 55% by weight, the amount added is 0.5% of the weight of hydroxyacetonitrile, stir and mix evenly at room temperature, then acidify with dilute sulfuric acid to pH value 5, preheat to 50°C; preheat ammonia water with a concentration of 25% by weight to 170°C; use metering pumps to enter the continuous reactor respectively, and the flow rate of hydroxyacetonitrile is 2m 3 / h, the reaction temperature is controlled at 120°C to 130°C, the reaction pressure is 0.5Mpa, and the residence time of the material in the reactor is 0.5 minutes; the reaction mixture at the outlet of the reactor is extremely cooled to 100°C, and the iminodiacetonitrile reaction liquid is obtained. Through analysis wherein iminodiacetonitrile content is 310g / L, and the content of hydroxyacetonitrile is 30g / L, and the content of aminotriacetonitrile is 10g / L, and the content of aminoac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com