Method for preparing light calcium hexaaluminate-magnesium aluminum spinel composite refractory material at low temperature by two-step method

A technology of magnesium-aluminum spinel and calcium hexaaluminate is applied in the field of two-step low-temperature preparation of light calcium hexaaluminate-magnesium-aluminum spinel composite refractory materials, and can solve the problems of poor product quality, high energy consumption, The problem of high firing temperature can achieve the effect of low wettability, good thermal conductivity and low solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] A method for preparing light calcium hexaaluminate-magnesium aluminum spinel composite refractory material at low temperature in a two-step method, the steps are:

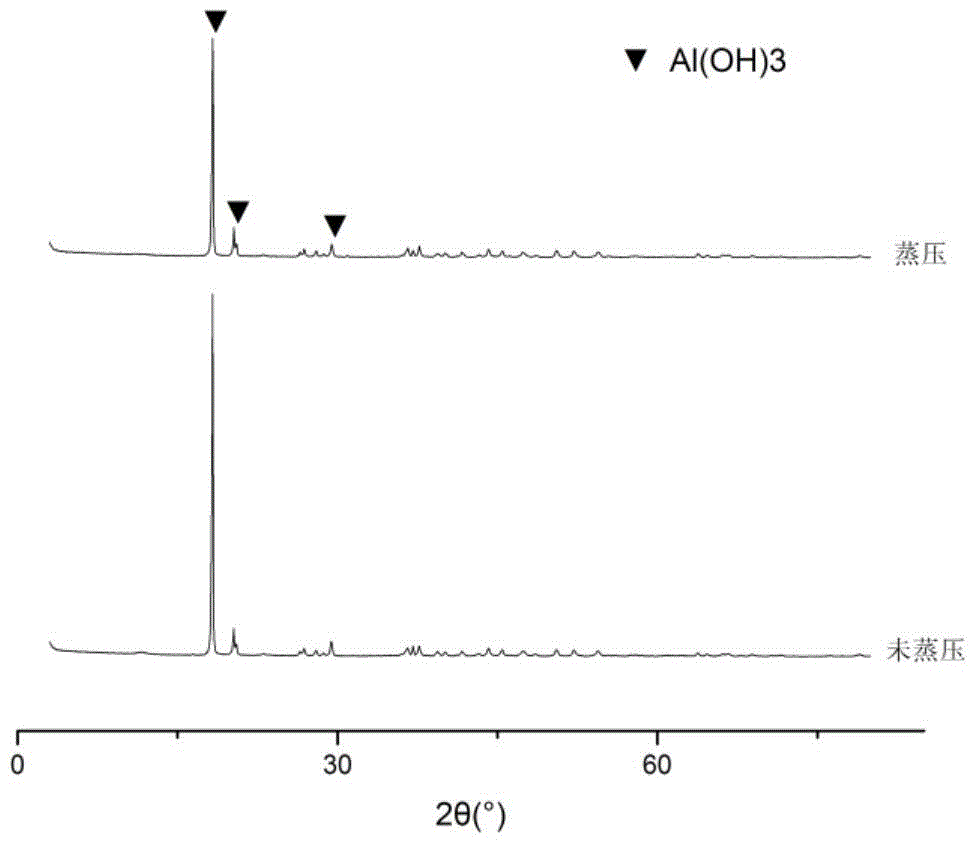

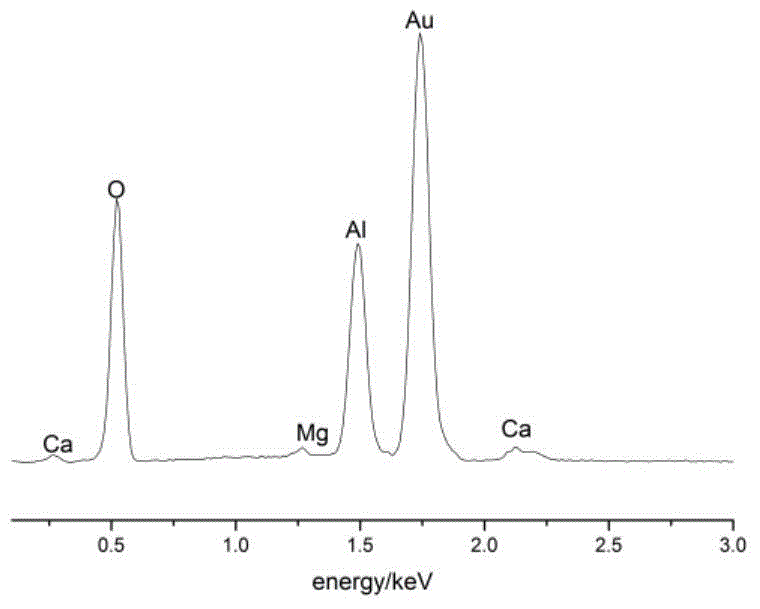

[0059] Grind the dolomite and industrial aluminum hydroxide with a crushing ball until the particle size is less than 0.15mm, and mix with a certain admixture for wet co-grinding for 4 hours; the molar ratio of the starting materials is: CaO:Al 2 o 3 :MgO=1:7:1, the admixture is 20% of the raw material mass, the water-solid mass ratio is 2.17, and the operating frequency of the planetary mill is set to 20Hz; the ground slurry is autoclaved in an autoclave for 10h, and the autoclaved The temperature is 150°C, and the stirring speed is 150r / min;

[0060] Take out the autoclaved slurry, separate the solid from the liquid, dry for 40 minutes, and make pellets with a diameter of about 1 mm; dry the pellets at 110°C for 8 hours, and calcinate them at 1400°C for 3 hours in a high-temperature furnace. The heating r...

Embodiment 2

[0062] A method for preparing light calcium hexaaluminate-magnesium aluminum spinel composite refractory material at low temperature in a two-step method, the steps are:

[0063] Grind the dolomite and industrial aluminum hydroxide with a crushing ball until the particle size is less than 0.15mm, and mix with a certain admixture for wet co-grinding for 3 hours; the molar ratio of the starting materials is: CaO:Al 2 o 3 : MgO=1:7.2:1, the admixture is 20% of the raw material mass, the water-solid mass ratio is 2.07, and the operating frequency of the planetary mill is set to 20Hz; the ground slurry is autoclaved in an autoclave for 8 hours, and the autoclaved The temperature is 150°C, and the stirring speed is 150r / min;

[0064] Take out the autoclaved slurry, separate the solid from the liquid, dry for 40 minutes, and make pellets with a diameter of about 1 mm; dry the pellets at 110°C for 8 hours, and calcinate them at 1450°C for 3 hours in a high-temperature furnace, with a...

Embodiment 3

[0066] A method for preparing light calcium hexaaluminate-magnesium aluminum spinel composite refractory material at low temperature in a two-step method, the steps are:

[0067] Grind the dolomite and industrial aluminum hydroxide with a crushing ball until the particle size is less than 0.15mm, and mix with a certain admixture for wet co-grinding for 3 hours; the molar ratio of the starting materials is: CaO:Al 2 o 3 : MgO=1:6.9:0.8, the admixture is 20% of the raw material mass, the water-solid mass ratio is 2.11, and the operating frequency of the planetary mill is set to 20Hz; the ground slurry is autoclaved in an autoclave for 8h, autoclaved The temperature is 150° C., and the stirring speed is 150 r / min.

[0068] Take out the autoclaved slurry, filter and dry it for 40 minutes, and then make pellets with a diameter of about 1mm; dry the pellets at 110°C for 8 hours, and calcinate them at 1500°C for 3 hours in a high-temperature furnace. The heating rate is: room temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com