Sewage air flotation scum defoaming machine

A scum defoamer and air flotation technology, which is applied in degassed water/sewage treatment, flotation water/sewage treatment, etc., can solve the difficulty of increasing the size of the mixer blade, the difficulty of removing scum and filter material, and the difficulty of scumming. Complex composition and other problems, to achieve the effect of accelerating the speed of foam breaking and sinking, and shortening the time of solid-liquid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Further description below in conjunction with accompanying drawings.

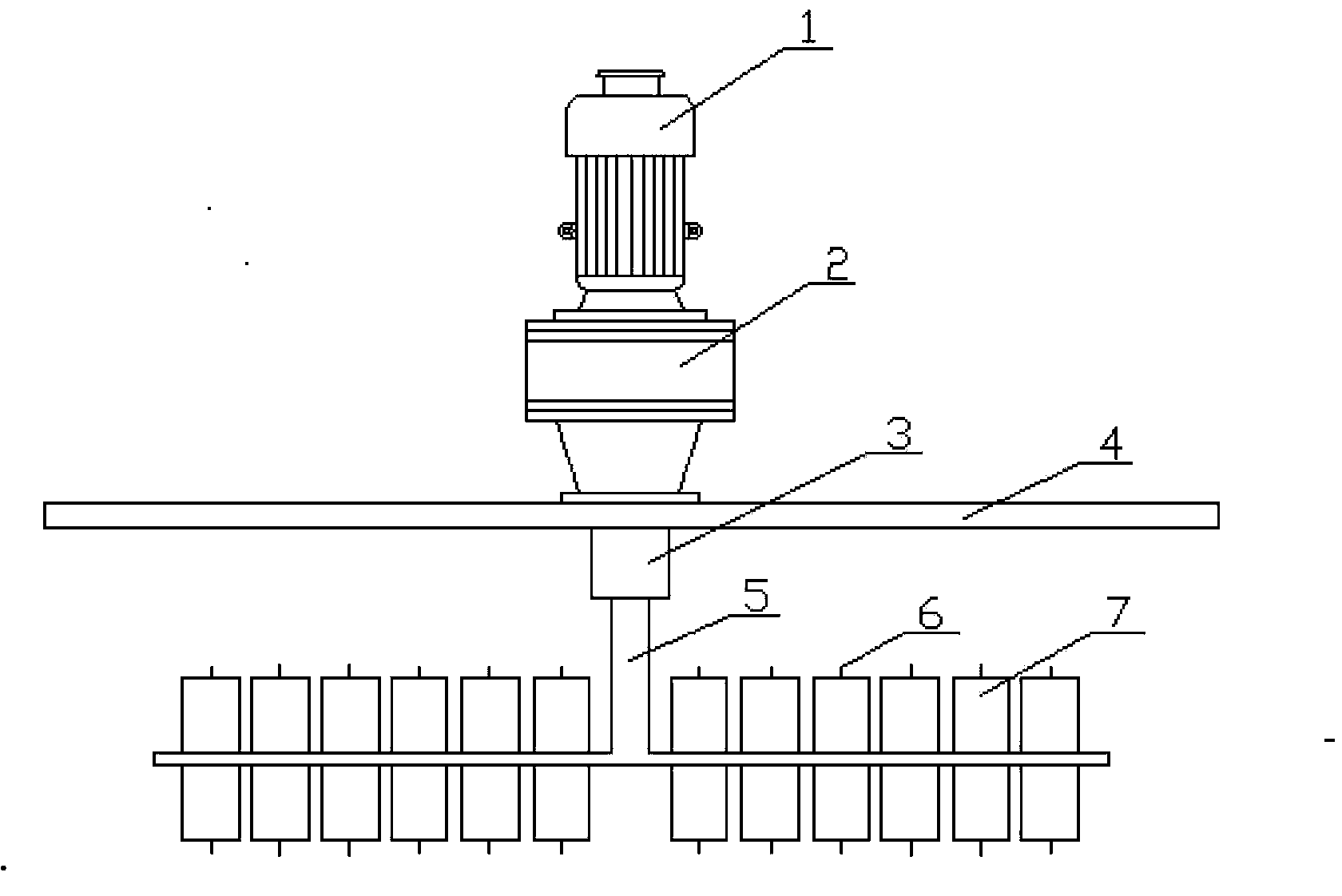

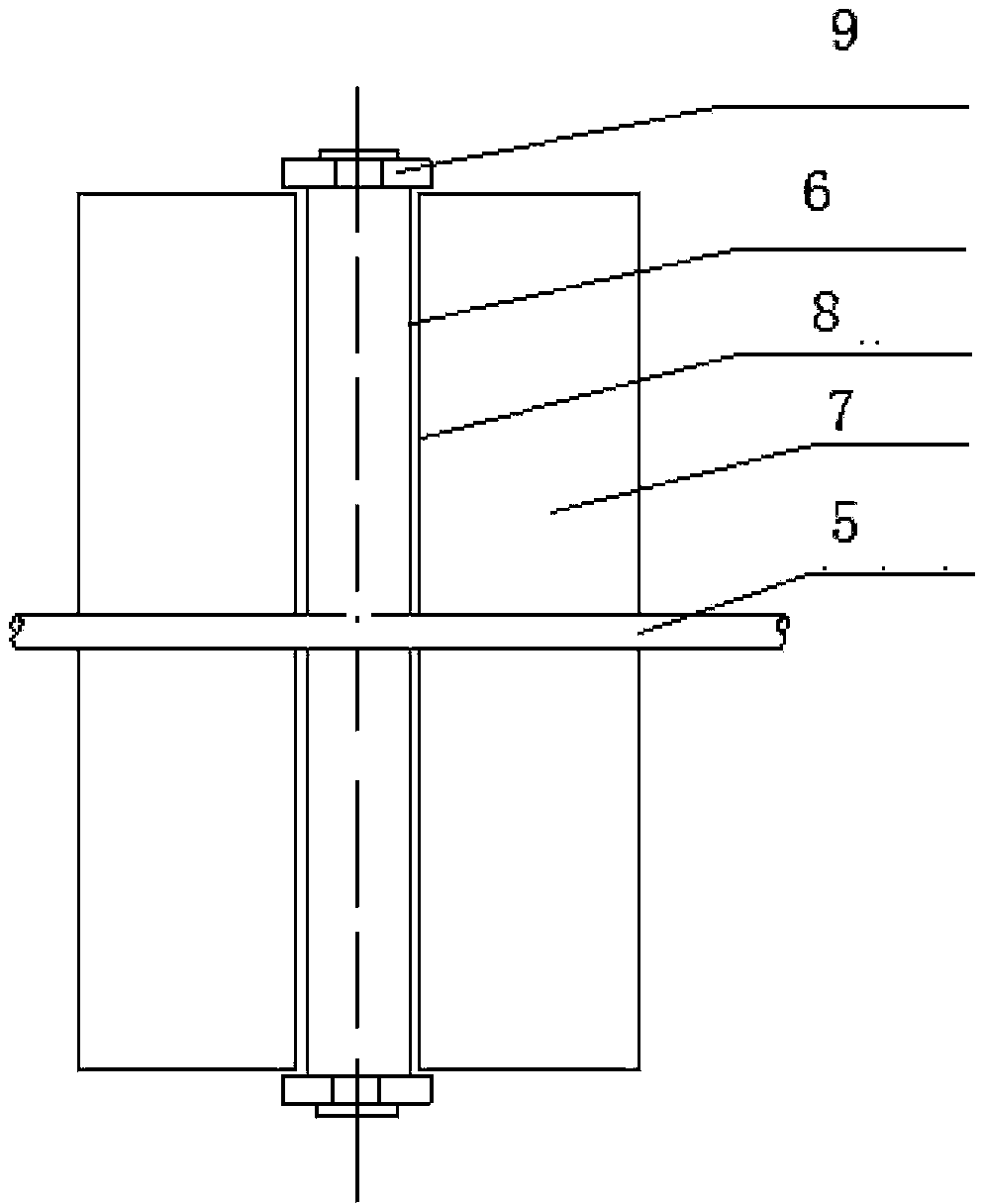

[0016] A sewage air flotation and scum defoaming machine, including a motor 1, the motor 1 is connected to a rotating rod 5 through a reducer 2 and a coupling 3, the rotating rod 5 is an inverted "T" shape, and the horizontal bar of the rotating rod 5 is distributed A plurality of fixed vertical shafts 6 are arranged, and blades 7 that can rotate around the fixed vertical shafts 6 are arranged on the fixed vertical shafts 6 . The motor 1 and the speed reducer 2 are arranged on the mounting bracket 4 , and the rotating rod 5 is below the mounting bracket 4 . The blades 7 are connected to the cross bar of the rotating bar 5 through the fixed vertical shaft 6 . The motor is connected with the control cabinet. A vertical metal pipe 8 is arranged in the middle of the blade 7, and a fixed vertical shaft 6 is inserted in the metal pipe 8. The inner diameter of the metal pipe 8 is slightly larger than the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com