Method for preparing porous carbon material for supercapacitor by activating rice husk with ionic liquid

A technology for supercapacitors and ionic liquids, applied in the field of preparation of porous carbon materials for supercapacitors, can solve the problems of low overall utilization rate of rice husks, pollute the environment, waste resources, etc., and achieve easy product structure, simple preparation process, and raw material sources rich effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

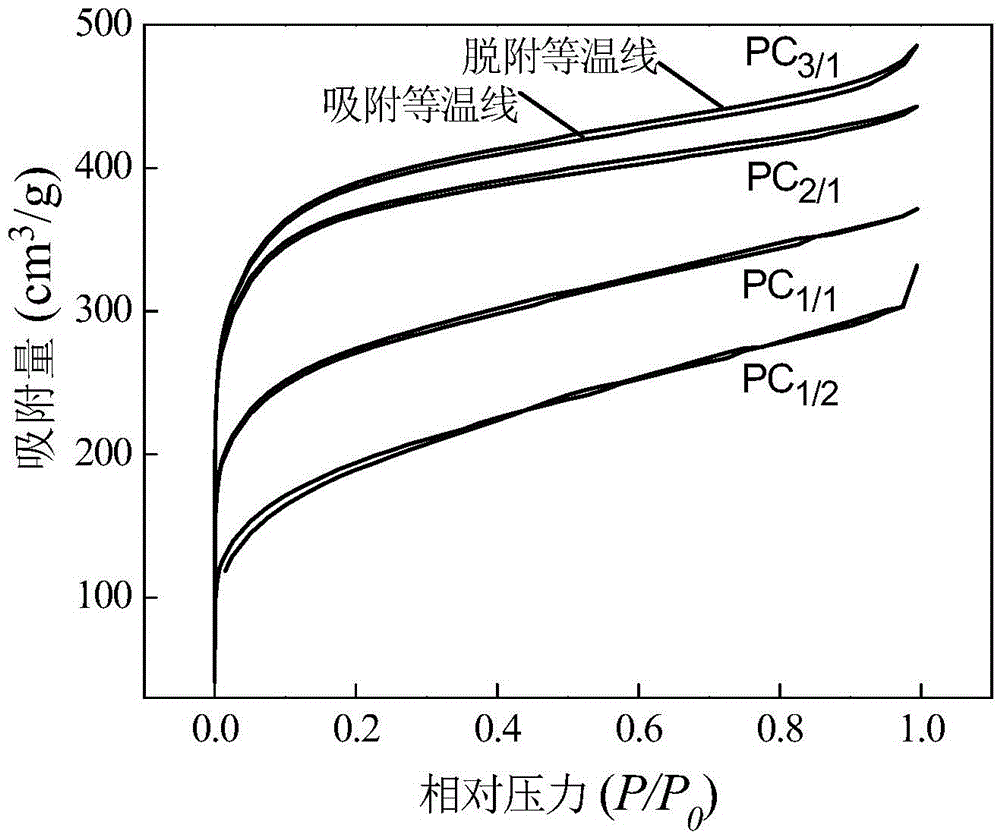

[0020] Porous carbon material PC 1 / 2 The specific preparation process is as follows:

[0021] (1) Pretreatment of reactants: 6g 1-butyl-3-methylimidazolium hexafluorophosphate (BMIMPF 6 ) ionic liquid was added into 150mL of absolute ethanol, ultrasonically oscillated for 30min to dissolve it completely, then 12g of deashed rice husk was added, stirred and ultrasonically oscillated for 1h, and then the obtained raw material mixture was allowed to stand for 12h, then soaked for 3h under vacuum conditions, After drying at a constant temperature of 80°C for 12 hours, the reactant was obtained;

[0022] (2) Preparation of porous carbon material: put the reactant obtained in step (1) into a corundum porcelain boat, then place the corundum porcelain boat in a box furnace, feed nitrogen into the box furnace for 40 minutes in advance Then, the nitrogen flow rate was fixed at 60mL / min, and the box-type furnace was heated to 330°C at a heating rate of 3°C / min. The box-type furnace wa...

Embodiment 2

[0024] Porous carbon PC 1 / 1 The specific preparation process is as follows:

[0025](1) Pretreatment of reactants: implement according to the same method as step (1) in Example 1. The difference is that the quality of the ionic liquid weighed is 9g, and the quality of the rice husk is 9g;

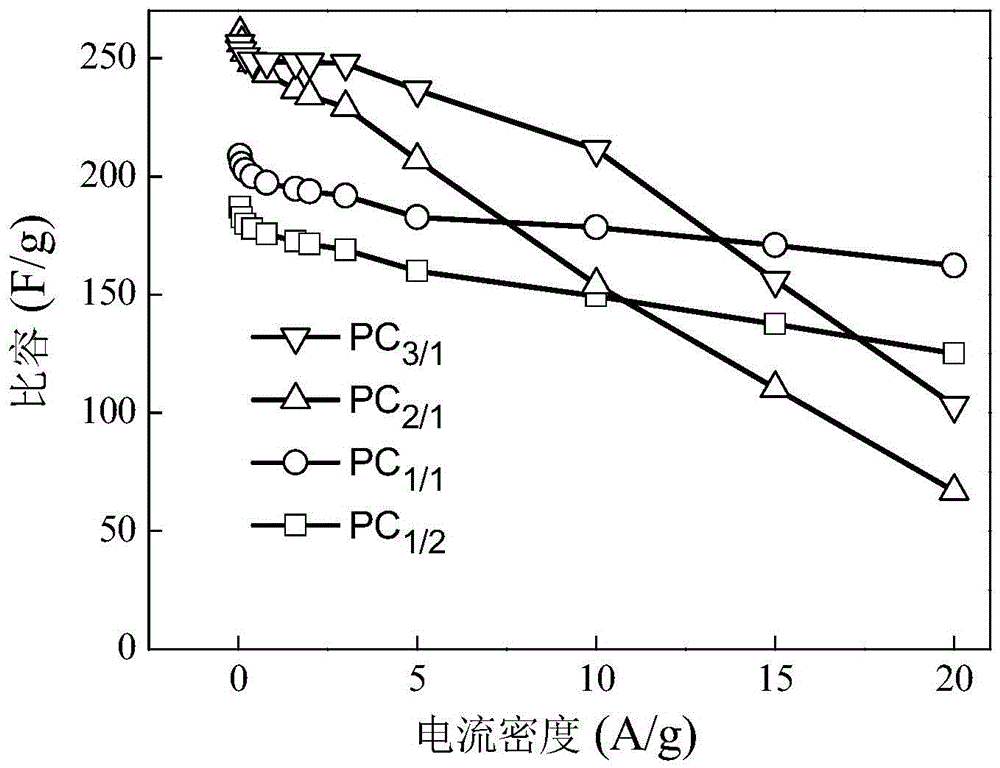

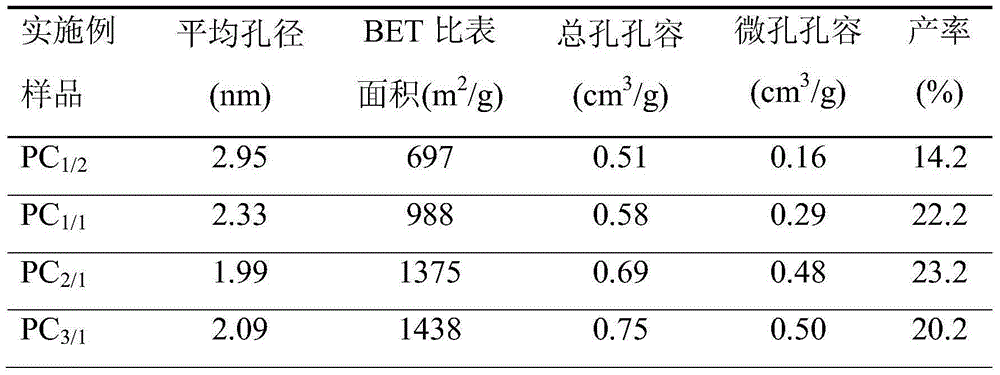

[0026] (2) According to the same method as step (2) in Example 1, the resulting porous carbon material is marked as PC 1 / 1 . Porous carbon PC 1 / 1 The specific surface area is 988m 2 / g, the average pore diameter is 2.33nm. At a current density of 0.05 A / g in 6 M KOH electrolyte, PC 1 / 1 The specific volume of the electrode material reaches 209F / g; at a current density of 20A / g, PC 1 / 1 The specific volume of the electrode material reaches 162F / g.

Embodiment 3

[0028] Porous carbon PC 2 / 1 The specific preparation process is as follows:

[0029] (1) Pretreatment of reactants: implement according to the same method as step (1) in Example 1. The difference is that the quality of the ionic liquid weighed is 12g, and the quality of the rice husk is 6g;

[0030] (2) According to the same method as step (2) in Example 1, the resulting porous carbon is marked as PC 2 / 1 . Porous carbon PC 2 / 1 The specific surface area is 1375m 2 / g, the average pore diameter is 1.99nm. At a current density of 0.05 A / g in 6 M KOH electrolyte, PC 2 / 1 The specific volume of the electrode material reaches 256F / g; at a current density of 20A / g, PC 2 / 1 The specific volume of the electrode material reaches 67F / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com