Fixing support shared by automobile transmission shaft and silencer

A technology for fixing brackets and mufflers, applied in power units, vehicle components, jet propulsion units, etc., can solve problems such as affecting the installation of other components, low NVH performance, and complex assembly processes, achieving compact layout, improved NVH performance, Solve the effect of insufficient layout space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing.

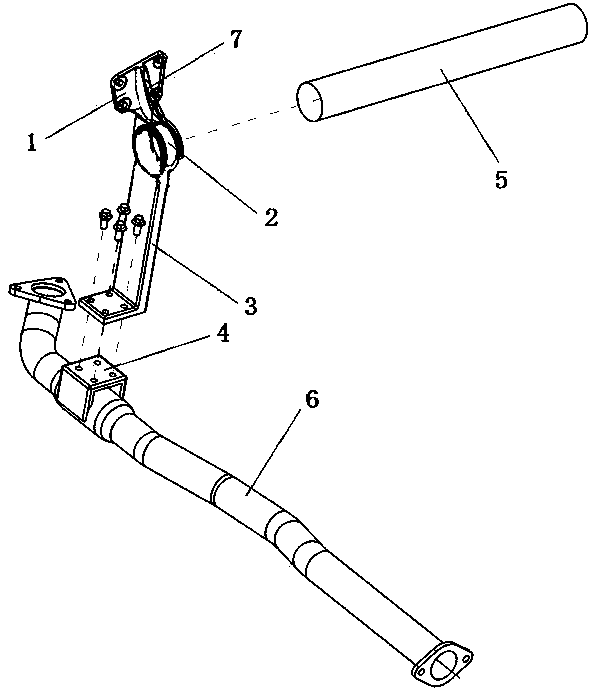

[0018] Such as figure 1 The fixed bracket shared by the automobile drive shaft and the muffler shown is an integral structure formed by aluminum alloy die-casting, which has a first connecting plate 1 fixed to the engine block by bolts, and a cylindrical bracket for supporting the drive shaft 5 of the automobile. The supporting sleeve 2 and the second connecting plate 3 fixed by bolt connection with the muffler 6, the first connecting plate 1 is parallel to the axis of the cylindrical supporting sleeve 2, and the first connecting plate 1 is connected to the cylindrical supporting sleeve through the reinforcing rib 7 perpendicular to it. The outer wall of 2 is connected, the second connecting plate 3 is an L-shaped structure, and its vertical part is perpendicular to the axis of the cylindrical supporting sleeve 2, and the top of the vertical part of the second connecting pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com