Eddy-type vacuum oil purifier

A vacuum oil purifier, vortex-type technology, applied in the direction of filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems that water and gas cannot be released in time, increase manufacturing cost, increase floor area, increase mechanical volume, etc. , to achieve the effect of convenient and fast transportation and movement, prolonging the oil flow time and reducing the volume of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples;

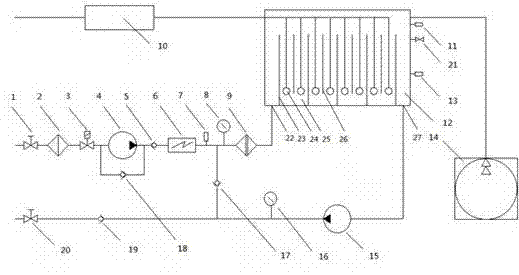

[0050] Such as Figure 1 As shown, it is a working principle diagram of a vortex vacuum oil purifier described in the embodiment of the present invention, which includes an oil inlet valve 1, a coarse filter 2, a solenoid valve 3, an oil inlet pump 4, Heater 6, fine filter 9, vacuum tank 12, oil discharge pump 15 and oil outlet valve 20, the interior of described vacuum tank 12 comprises multiple sets of eddy current oil circuit separators 23 and oil guide plates 26 arranged in parallel and staggered, in the order Air bubble generators 24 are also arranged in parallel between the staggered eddy current oil circuit separators 23 and oil guide plates 26, so that the vortex oil circuit separators 23, air bubble generators 24 and oil guide plates 26 are par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com