Nondestructive ceramic detection device and detection method thereof

A technology of non-destructive testing and testing methods, applied in the direction of measuring devices, material analysis through optical means, instruments, etc., can solve the problems of insufficiently advanced testing methods, limited testing range, and complicated testing process, so as to prevent manual testing errors and detect The process is simple and fast, and the test results are accurate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

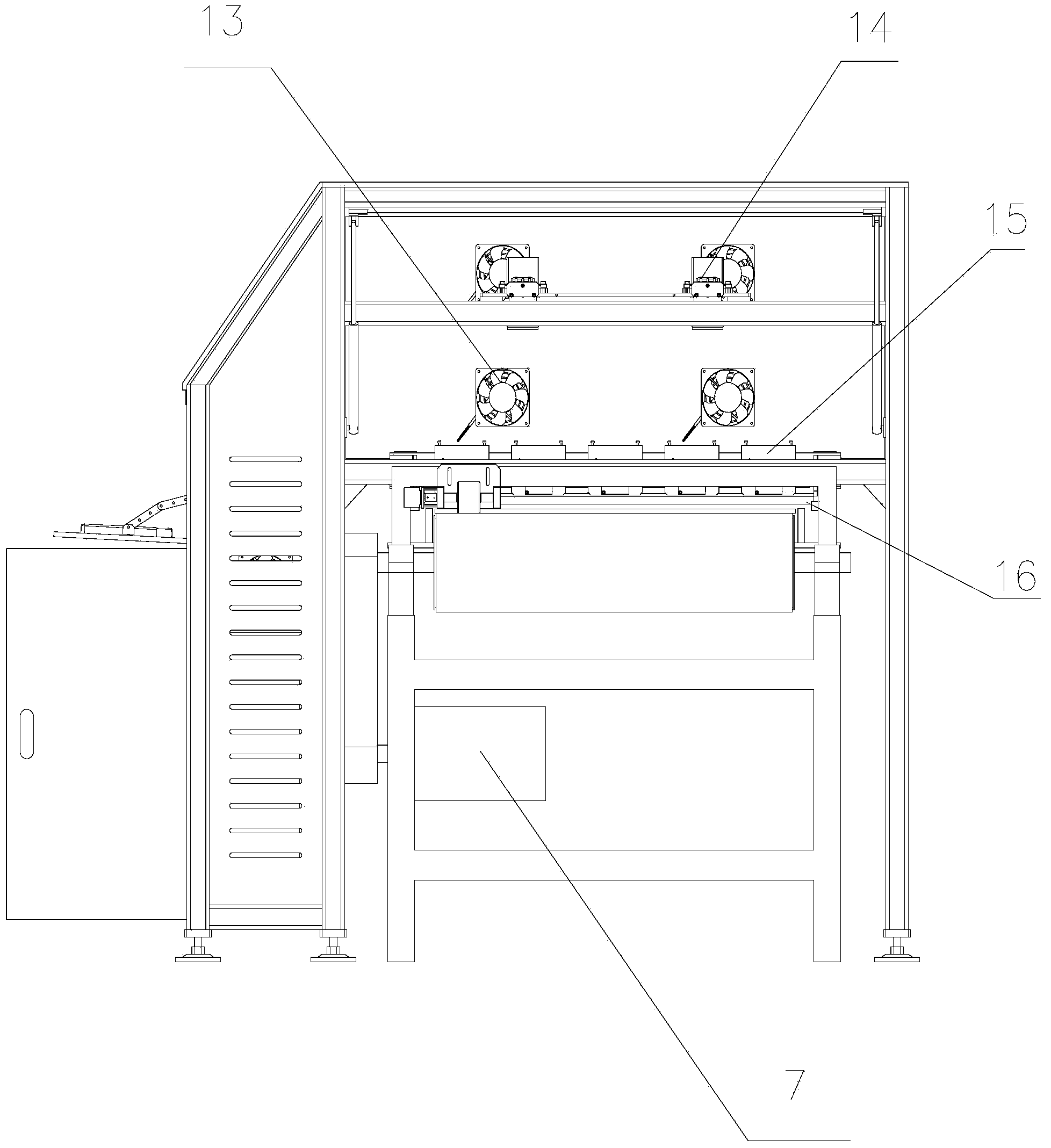

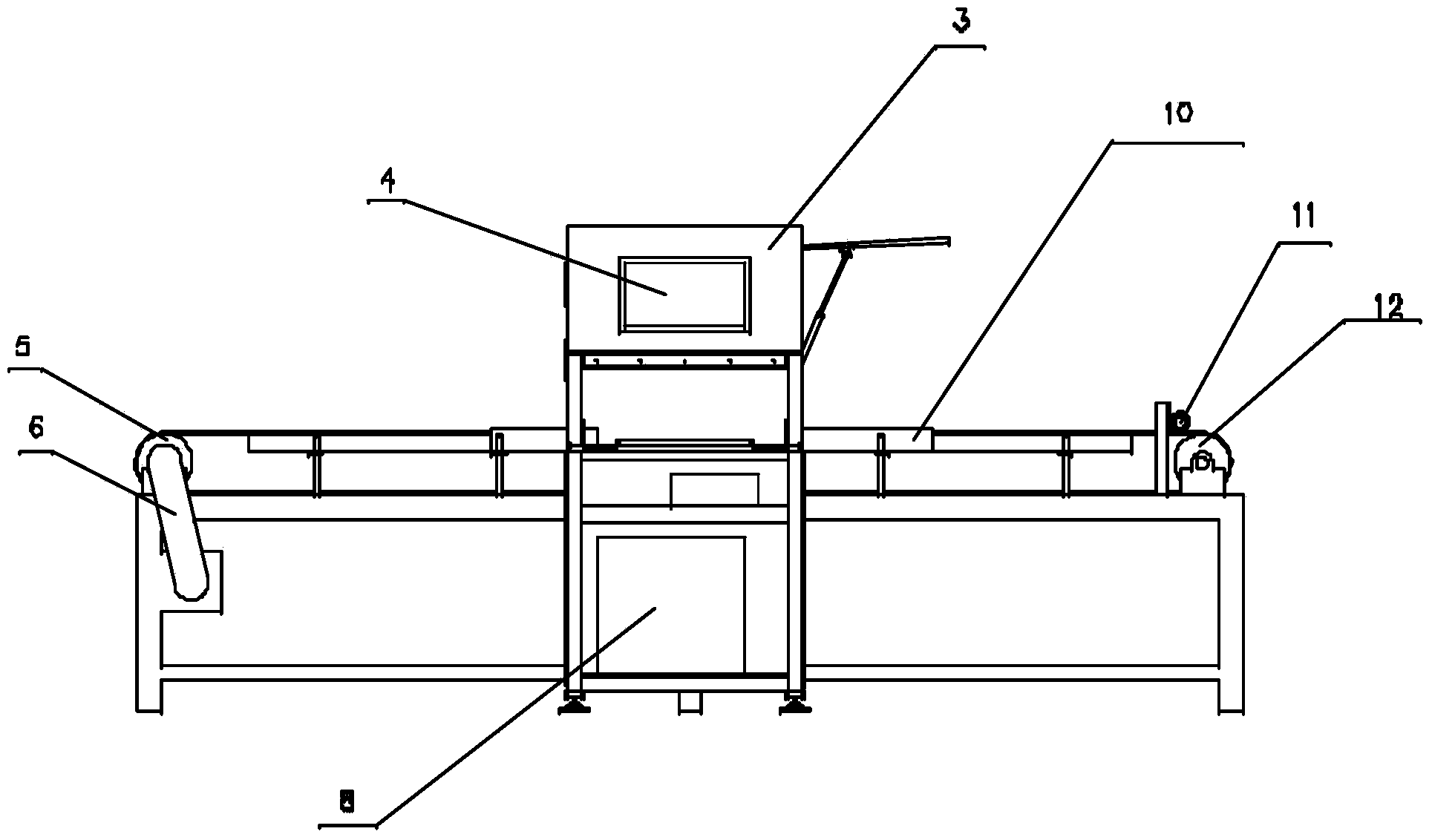

[0041] This embodiment provides nondestructive testing equipment for ceramic tiles. The nondestructive testing equipment for ceramic tiles is mainly composed of a control system, a detection system, and a motion system, wherein the control system is composed of a host computer, an operation interface, and a control box. Sensors, linear light sources, and motion systems are composed of motors, conveyor belts, timing belts, and encoders.

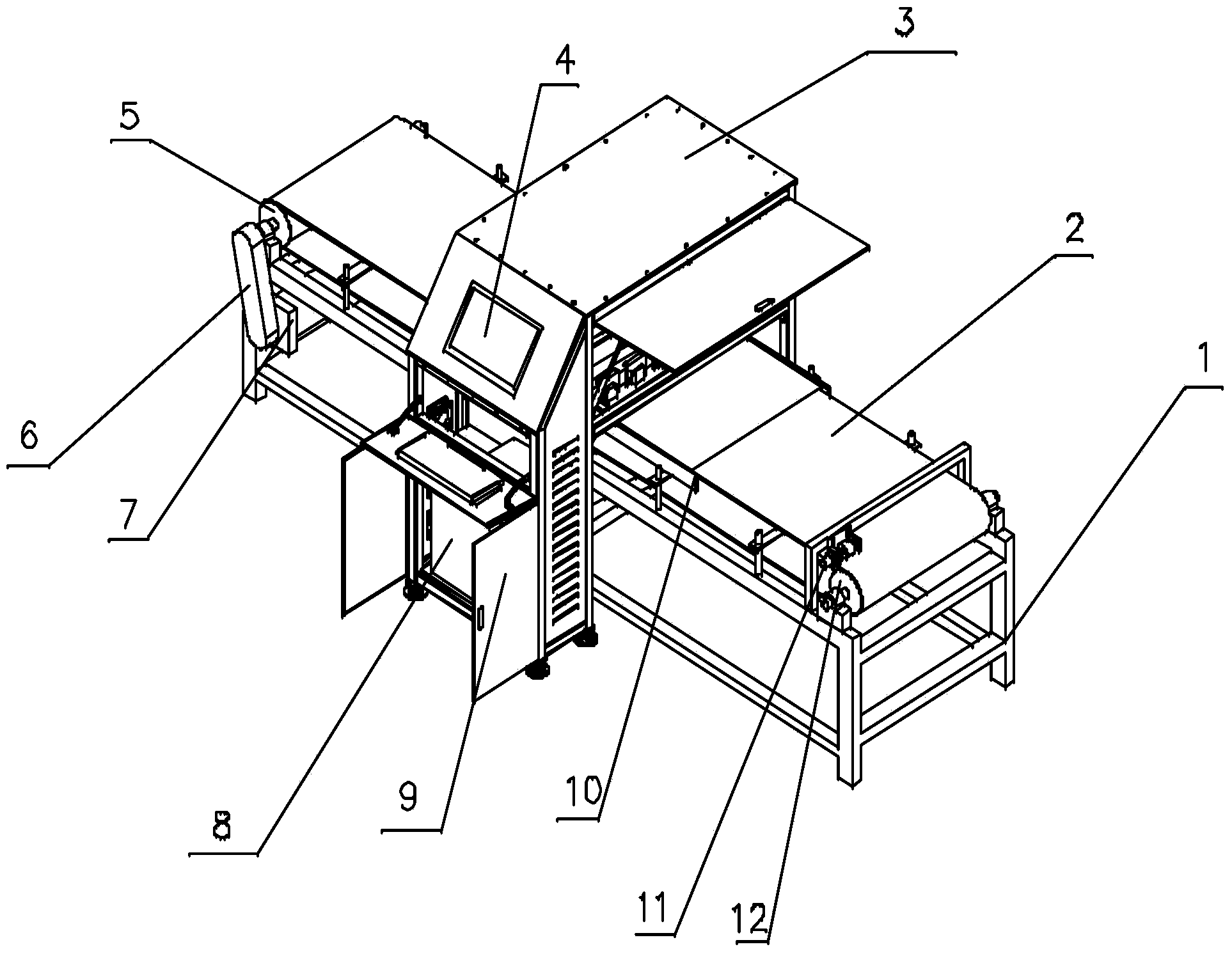

[0042] Such as figure 1 , figure 2 , image 3As shown, the nondestructive testing equipment for ceramic tiles in this embodiment includes a frame 1, a conveyor belt 2, a machine cover 3, an operation interface 4, a driving wheel 5, a timing belt 6, a motor 7, a detection host 8, a control box 9, a positioning Baffle 10 , encoder 11 , driven wheel 12 , fan 13 , linear CCD camera 14 , laser displacement sensor 15 and linear light source 16 .

[0043] The frame 1 is a rectangular parallelepiped frame, and the bottom of the rectangular paralle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com