Crucible

A crucible and body technology, applied in the crucible field of evaporation process, can solve the problems of time-consuming, lower production efficiency, poor thermal conductivity, etc., and achieve the effects of avoiding sealing, reducing heat loss, and avoiding bursting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

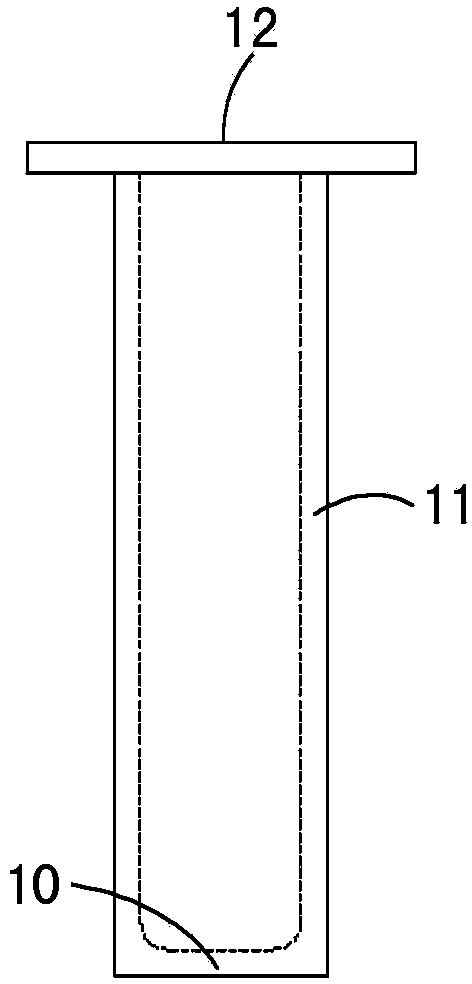

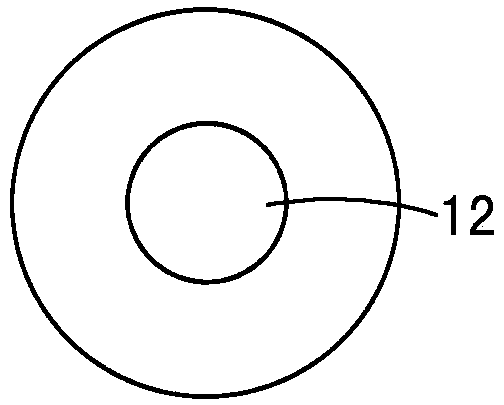

Embodiment approach 1

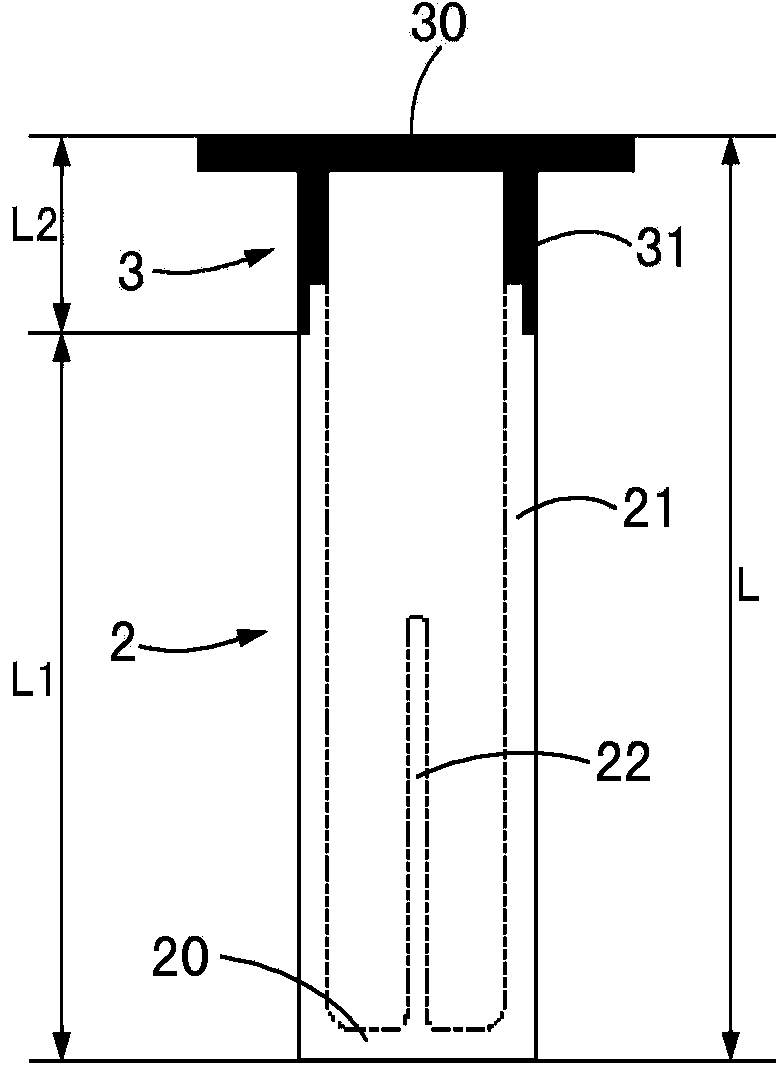

[0033] see Figure 2A , Figure 2B with Figure 2C . The first embodiment of the crucible of the present invention includes a first body 2 and a second body 3 . The length L2 of the second body 3 is less than the length L1 of the first body 2, for example, the length L2 of the second body 3 is 1 / 6 of the length L1 of the first body 2, of course it is not limited to this, it can be based on the overall length of the crucible Factors such as L are reasonably determined. Usually, the length L2 of the second body 3 increases with the overall length L of the crucible. Generally speaking, the length L2 of the second body 3 is 1 / 10-10 of the length L1 of the first body 2. 1 / 5 range is feasible. The thermal conductivity of the second body 3 is greater than that of the first body 2, which can be achieved by selecting different materials to manufacture different bodies, for example, the first body 2 is made of non-metallic materials such as alumina, quartz, ceramics or carbon-carbon...

no. 2 approach

[0040] see Figure 3A with Figure 3B . The second embodiment of the crucible of the present invention differs from the first embodiment only in the connection structure between the second body 3 and the first body 2 .

[0041] Specifically, the first connecting portion of the first body 2 is the first inclined surface 212 on the upper end of the first side wall 21, and the second connecting portion of the second body 3 is the second inclined surface on the lower end of the second side wall 31. portion 312 , the second slope portion 312 is in contact with the first slope portion 212 , and the first slope portion 211 is disposed inside the second slope portion 311 , and of course the first slope portion 211 is disposed outside the second slope portion 311 . When the crucible is heated and expanded, the second body 3 and the first body 2 deform differently due to the difference in thermal conductivity. At this time, the second body 3 can move up and down along the length direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com