Betaine-polymer oil displacement composition and preparation method thereof

A technology of polymer and betaine, which is applied in drilling compositions, chemical instruments and methods, and earthwork drilling and production, can solve problems such as formation and oil well damage, poor oil displacement efficiency, corrosion equipment and pipelines, etc., and achieve The effect of good technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

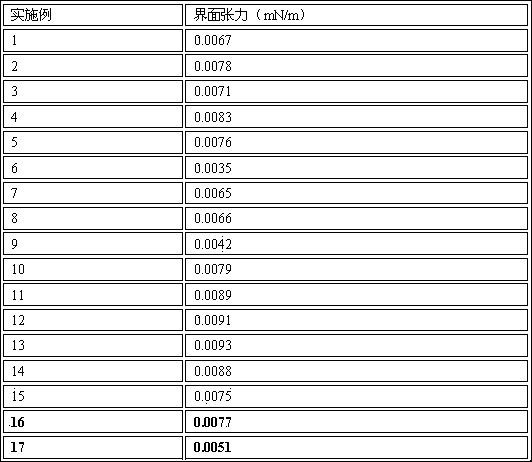

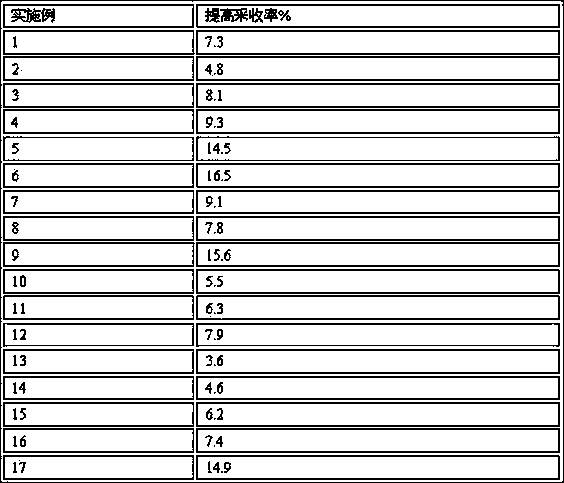

Examples

Embodiment 1

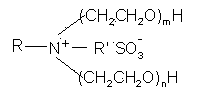

[0027] 1. Preparation of betaine surfactant

[0028] a) Add octadecyl primary amine (1 mol) to a reactor equipped with a condensing device and a stirring device, and when heating to 150°C while blowing nitrogen, add ethylene oxide (2 mol) after heating for 40 minutes, The temperature was maintained at 155°C and the reaction was stirred for 1 hour. Cool down to 80°C, add barium hydroxide as a catalyst, heat to 140°C, turn on the vacuum system, dehydrate under high vacuum for 1 hour, and then use nitrogen to blow 4 times to remove the air in the system, and then adjust the reaction temperature of the system to Slowly feed ethylene oxide (4 moles) at 165°C, and control the pressure <0.80MPa for alkoxylation until the end of the reaction. After cooling, use oxalic acid to neutralize, filter, and dehydrate to obtain octadecyl polyoxyethylene ( n+m=6) ether tertiary amine. Wherein the consumption of barium hydroxide is 0.5wt% of octadecyl primary amine and ethylene oxide weight. ...

Embodiment 2

[0040] 1. Preparation of betaine surfactant

[0041] a) Add octadecyl primary amine (1 mol) to a reactor equipped with a condensing device and a stirring device, and when heating to 150°C while blowing nitrogen, add ethylene oxide (2 mol) after heating for 40 minutes, The temperature was maintained at 155°C and the reaction was stirred for 1 hour. Cool down to 80°C, add barium hydroxide as a catalyst, heat to 140°C, turn on the vacuum system, dehydrate under high vacuum for 1 hour, and then use nitrogen to blow 4 times to remove the air in the system, and then adjust the reaction temperature of the system to Slowly feed ethylene oxide (1 mole) at 165°C, and control the pressure <0.80MPa to carry out alkoxylation reaction until the end of the reaction. After cooling, use oxalic acid to neutralize, filter, and dehydrate to obtain octadecyl polyoxyethylene ( n+m=3) ether tertiary amine. Wherein the consumption of barium hydroxide is 0.5wt% of octadecyl primary amine and ethyle...

Embodiment 3

[0047] 1. Preparation of betaine surfactant

[0048] a) Add octadecyl primary amine (1 mol) to a reactor equipped with a condensing device and a stirring device, and when heating to 150°C while blowing nitrogen, add ethylene oxide (2 mol) after heating for 40 minutes, The temperature was maintained at 155°C and the reaction was stirred for 1 hour. Cool down to 80°C, add barium hydroxide as a catalyst, heat to 140°C, turn on the vacuum system, dehydrate under high vacuum for 1 hour, and then use nitrogen to blow 4 times to remove the air in the system, and then adjust the reaction temperature of the system to Slowly feed ethylene oxide (6 moles) at 165°C, and control the pressure <0.80MPa to carry out alkoxylation reaction until the end of the reaction. After cooling, use oxalic acid to neutralize, filter, and dehydrate to obtain octadecyl polyoxyethylene ( n+m=8) ether tertiary amine. Wherein the consumption of barium hydroxide is 0.5wt% of octadecyl primary amine and ethy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com