Compound functional agricultural machinery finishing powder coating and production process thereof

A powder coating and functional technology, applied in powder coatings, bulk chemical production, polyester coatings, etc., can solve the problems of cumbersome production process, not very easy, and many devices, so as to reduce production costs, reduce electric energy, The effect of lowering the baking temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Preparation of polyester / acrylic resin composite 1: It is prepared by mixing polyester resin and acrylic resin in a weight ratio of 7:3, and reacting in a high-temperature reactor at 150° C. for 1 hour.

[0042] Preparation of epoxy-modified acrylic resin: using methyl methacrylate, acrylic acid, octyl acrylate, styrene, hydroxypropyl acrylate, trimethylolpropane triacrylate as monomers, benzoyl peroxide as initiator, E-44 epoxy resin is used as modifier and polymerized.

[0043] Preparation of nanocomposite cross-linking agent: 4,5-imidazole dicarboxylic acid and benzimidazole-5,6-dicarboxylic acid as sensitized organic ligands, grafted onto mesoporous SiO through covalent bonds 2 On the nanoparticles, a nanocomposite cross-linking agent is prepared.

[0044] The glass powder used is VX-SP imported from Japan.

[0045] The polyester resin is 9855 polyester resin supplied by Baotian New Materials.

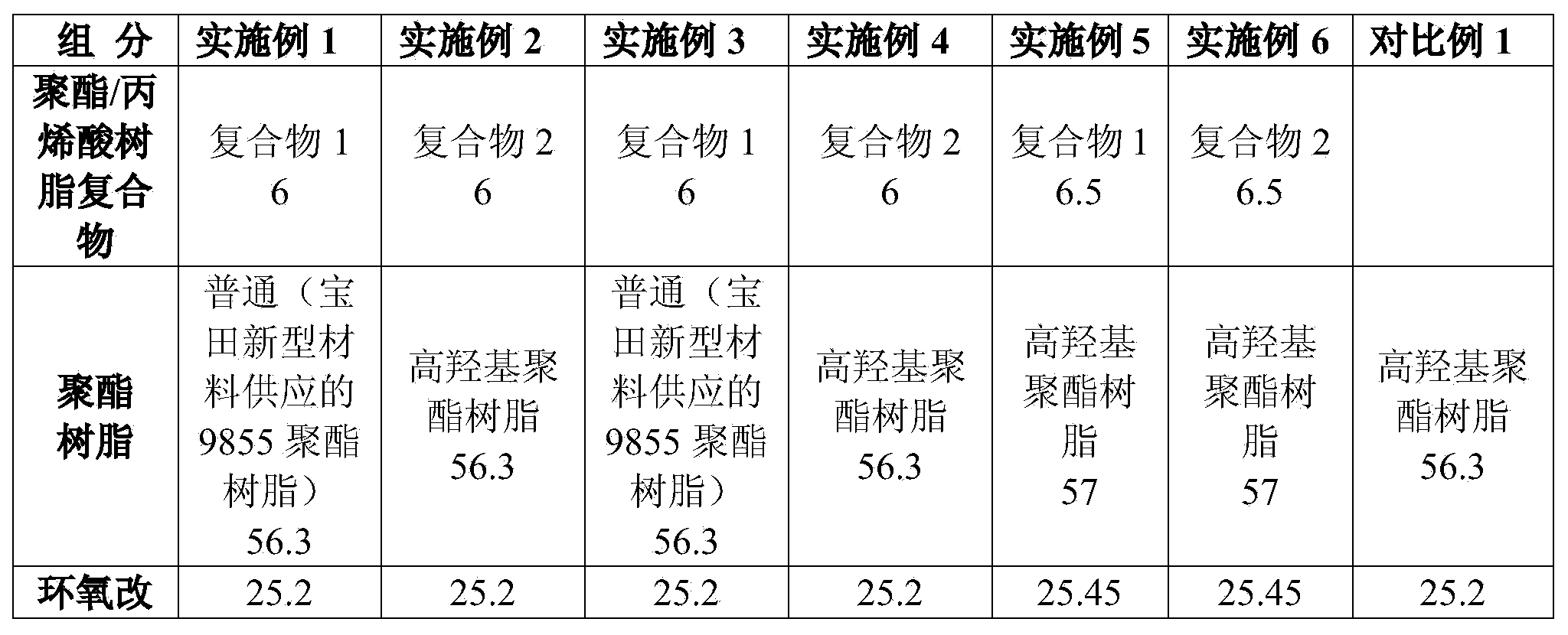

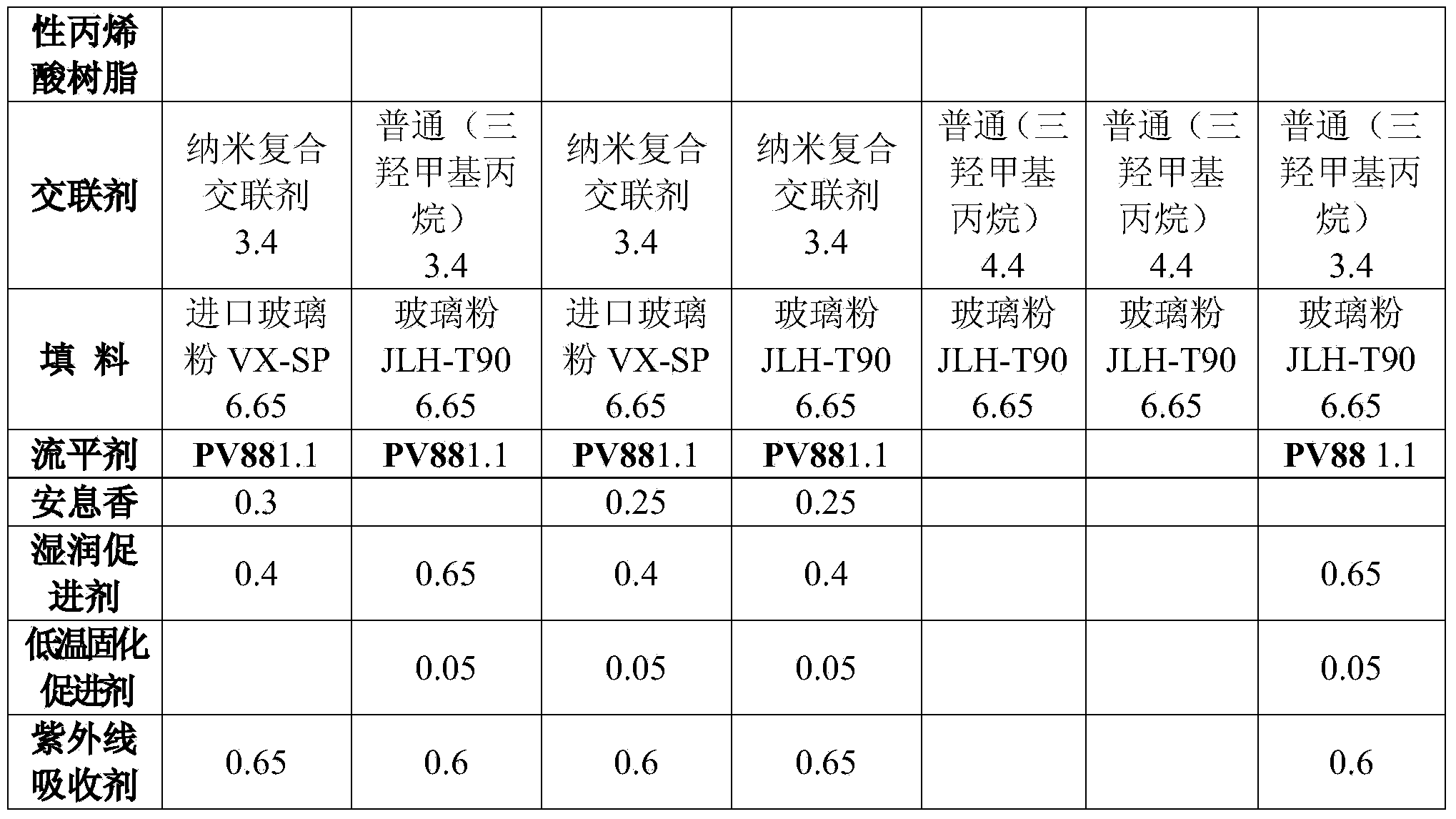

[0046] The raw material components of the powder coating are shown i...

Embodiment 2

[0050] This embodiment is basically the same as Embodiment 1, and its difference is:

[0051] To prepare polyester / acrylic composite 2, react for 1.5 hours.

[0052] The method of CN103467714A is adopted to prepare high hydroxyl polyester resin.

[0053] The crosslinking agent is trimethylolpropane.

[0054] The nano-scale glass powder is Jingshan nano-scale glass powder JLH-T90 produced and sold by Shenzhen Jinlonghui Industrial Co., Ltd.

[0055] In addition, the additives are different, see Table 1 for details.

Embodiment 3

[0057] This embodiment is basically the same as Embodiment 1, the difference is that the additives are different, the temperature of the supercritical fluid tank is set to 120 ° C, after heating to the set temperature, the temperature is kept constant for 5 minutes, and the rotation speed of the shearing element is 150 rpm , with a shear mixing time of 10 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com