A kind of lightweight high-strength inflatable membrane material and preparation method thereof

An inflatable film, weaving technology, applied in chemical instruments and methods, lamination, layered products, etc., can solve the problems of gas and moisture resistance, poor friction and corrosion resistance, low wind, rain and snow load capacity, and high requirements. , to achieve the effect of good gas and water resistance, improved tensile strength and improved peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

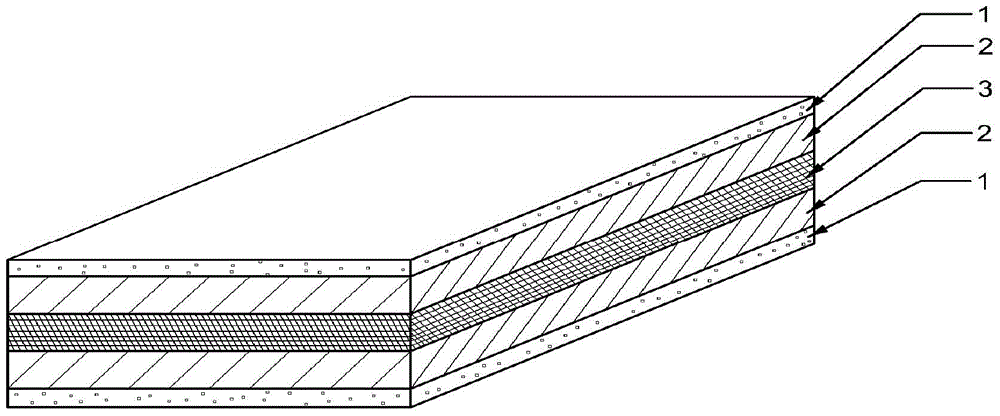

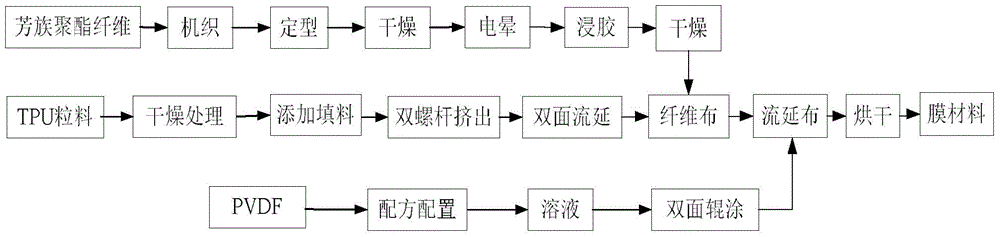

[0028] An inflatable film material provided by the present invention consists of a weather-resistant layer, a welding barrier layer, a load-bearing layer, a welding barrier layer, and a weather-resistant layer from the outside to the inside. Excellent performance characteristics of cleanliness.

[0029] The present invention will be further described below by embodiment.

[0030] The weather-resistant layer of the inflatable membrane material is located on the outermost layer of the membrane material to resist the sun's strong ultraviolet radiation and atmospheric and environmental corrosion. 11 parts by weight of resin, 14 parts by weight of pigment, and 55% of ethyl acetate solvent. This layer of film is applied to the outermost layer of the air-filled film material by roller coating, which can be well attached to the welding barrier layer. Has excellent weather resistance, wrinkle resistance, abrasion resistance and self-cleaning properties

[0031] The welding barrier l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com