Wear-resistant spiral blade for concrete mixing tank

A technology of helical blades and mixing tanks, which is applied in the field of wear-resistant helical blades of concrete mixing tanks, and can solve the problems of poor mixing, feeding and unloading performance of mixing tanks, poor performance of feeding and discharging materials and mixing of mixing tanks, and easy breakage of blade welding and other problems, to achieve the effect of smooth feeding and discharging, improved stirring performance, and firm welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

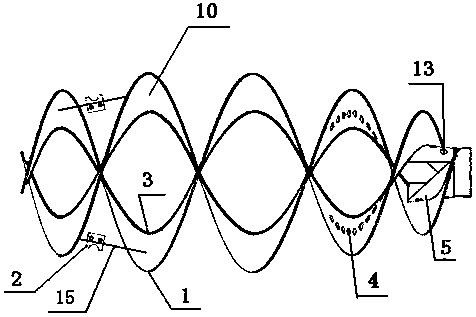

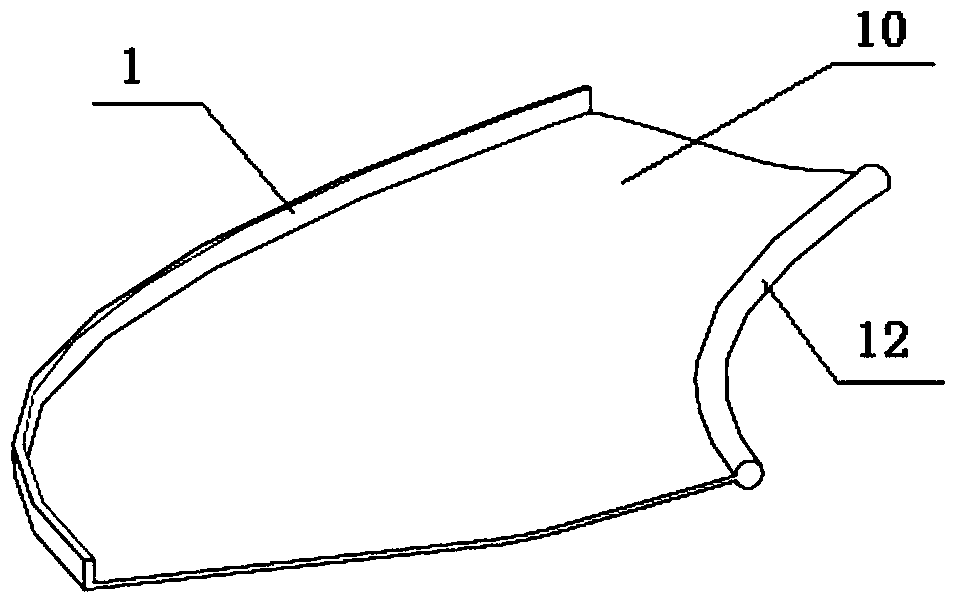

[0022] The following combination figure 1 , figure 2 , image 3 Specific embodiments of the present invention will be described in detail.

[0023] A wear-resistant helical blade for a concrete mixing tank. The tank body is divided into a front cone 7, a middle cylinder 8, and a rear cone 9. A pair of helical blades 10 adopts a non-equal angle logarithmic helix design with different pitches and helical angles. It is uniquely concave and realizes the three-dimensional mixing function; a pair of mixing blades 2 are arranged at the place where the inner pitch of the front cone 7 is relatively large. Two adjacent blades 10; a central cylinder 5 is provided in the rear cone 9, one end of the central cylinder 5 is straight and fixedly connected to the tank mouth 14, and the other end is a notch horn shape, and different numbers of through holes 13 are arranged on the horn surface. Conducive to smooth feeding, the end of the blade 10 is welded on the outer wall of the central cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com