Grain-oriented electrical steel plate

An electromagnetic steel plate, orientation technology, applied in the direction of inorganic material magnetism, electron beam welding equipment, laser welding equipment, etc., can solve the problems of magnetic domain width expansion, iron loss deterioration, eddy current loss increase, etc. The effect of reducing iron loss and improving energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] Prepare the magnetic flux density B in the rolling direction with a plate thickness of 0.23mm 8 It is 1.94T and has a two-layer coating (silicon dioxide-phosphate coating) on the surface of the steel base with a coating mainly composed of forsterite and a coating made of sintering an inorganic treatment liquid on the coating. Coils of film grain-oriented electrical steel sheets.

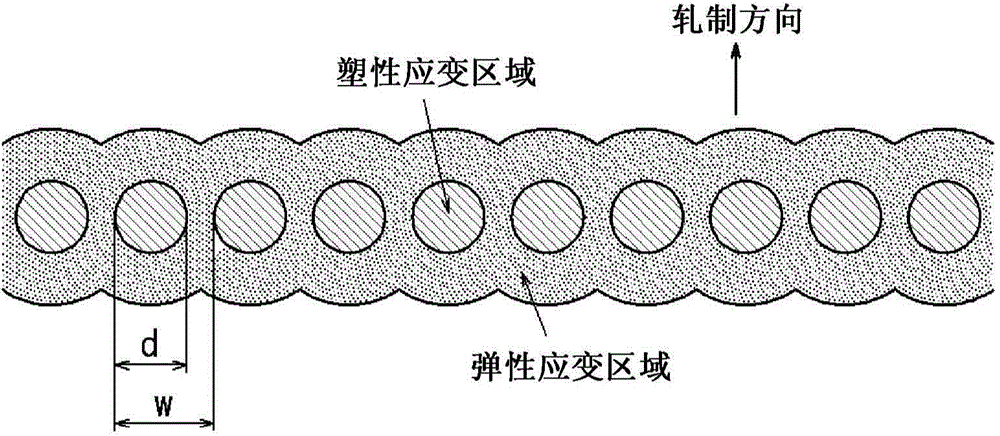

[0080] First, a veneer sample with a width of 100 mm and a length of 400 mm was cut out from the coil, and irradiated with a Q-switched pulse-oscillated fiber laser to perform magnetic domain refining treatment. By changing the beam diameter of the laser in the range of 0.05 to 0.6mm by defocusing, the repetition interval in the width direction is set to 0.1 to 1.2mm, and the output power that minimizes the iron loss is searched for.

[0081] Here, by increasing the beam diameter, the beam output power is increased in a manner sufficient to introduce sufficient thermal strain corresponding ...

Embodiment 2

[0090] The same grain-oriented electrical steel sheet as in Example 1 was irradiated with electron beams to refine the magnetic domains.

[0091] The electron beam is set at accelerating voltage: 60kV, beam diameter: 0.25mm, and after stopping at one point for 10ms, it moves to the next irradiation point at repeated intervals of 0.34mm and 0.5mm. Otherwise, follow the conditions described in Table 2 Irradiate. Furthermore, the width of the plastic strain region was 0.2 mm, and the conditions for minimizing the iron loss were searched for, and this was fabricated into a transformer core in the same manner as in Example 1, and the iron loss and noise were measured.

[0092] [Table 2]

[0093]

[0094] As shown in Table 2, the result was obtained that the coil irradiated with electron beams had an iron loss value smaller than that of Example 1 by 22 W or more.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Iron loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com