Pin of intelligent bus jack box

A technology for plug-in boxes and busbars, which is applied in the direction of fully enclosed busbar devices, connections, clamping/spring connections, etc. It can solve problems such as equipment burnout, short-circuiting of pins, loose contact, etc., to avoid offset or skew, Improved positioning effect and reliable contact fastening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

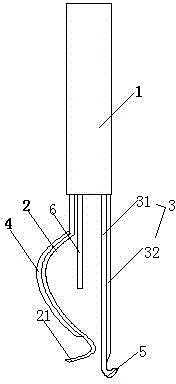

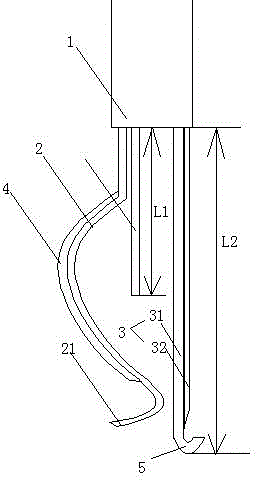

[0017] As shown in the figure, a smart bus plug-in box pin includes a central copper column 1, wherein a clamping part 2 is provided on one side of the lower end of the central copper column 1, and a fitting part 3 is provided on the other side. The clamping part 2, the bonding part 3 and the central copper column 1 are of an integrated structure. The upper end of the clamping part 2 is linear, the lower end is arc-shaped, and the bottom end is turned outward to form a guide part 21. The clamping part 2 The clamping part 2 is covered with a manganese steel sheet 4, the manganese steel sheet 4 is fixedly connected with the clamping part 2, and the lower end of the manganese steel sheet 4 is against the outer peripheral surface of the clamping part 2; the fitting part 3 includes a first The fitting board 31 and the second fitting board 32, the first fitting board 31 has a linear structure, and the bottom end of the first fitting board is turned outwards in an arc shape to form a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com