A managed pressure drilling method and device for a single throttle channel adapting to large flow rate changes

A pressure-management drilling and flow channel technology, which is applied in the wellbore pressure and flow control of natural gas drilling and petroleum fields, can solve problems such as co-existence of blowout and leakage, narrow density window, etc., and achieve equipment cost reduction, simplified structure, and simplified MPD equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

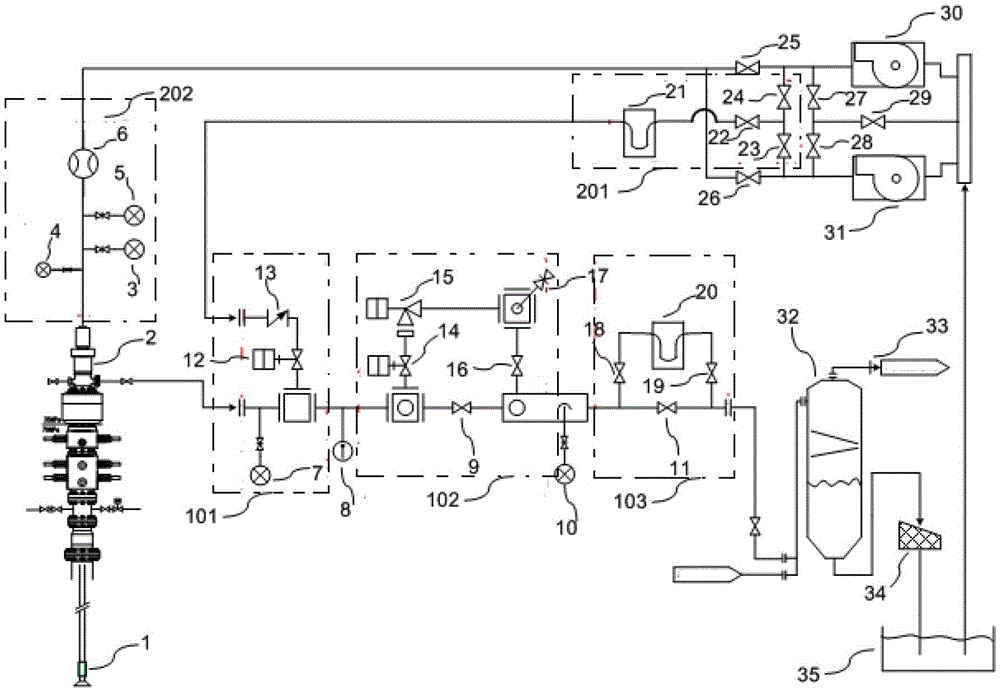

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0033] figure 1 It is a schematic diagram of the device of the present invention. Except that the drilling team is equipped with relevant equipment, the equipment of the present invention is mainly composed of connecting manifold 101, automatic choke manifold 102, wellhead return flow measurement system 103, back pressure compensation manifold and flow measurement system 201, standpipe measurement system 202, Rotating blowout preventer 2, composed of PWD1. The main circulation channel of drilling fluid is: inhaled by the mud tank 35, pumped into the drill string by the drilling pump 30 through the standpipe measurement system 202, then circulated out of the wellhead by the wellbore, and enters the connecting manifold through the wellhead rotary blowout preventer 2 suppressing pressure 101 first inlet, throttling to the automatic throttling manifold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com