Novel jacking pipe intersegment overhaul well

A maintenance well and pipe jacking technology, which is applied to water conservancy projects, artificial islands, underwater structures, etc., can solve problems such as subsidence, difficulty in digging soil, retraction of pipe joints, loosening and water leakage, etc., and achieves simple construction, flexible setting, Solve the effect of excavation support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

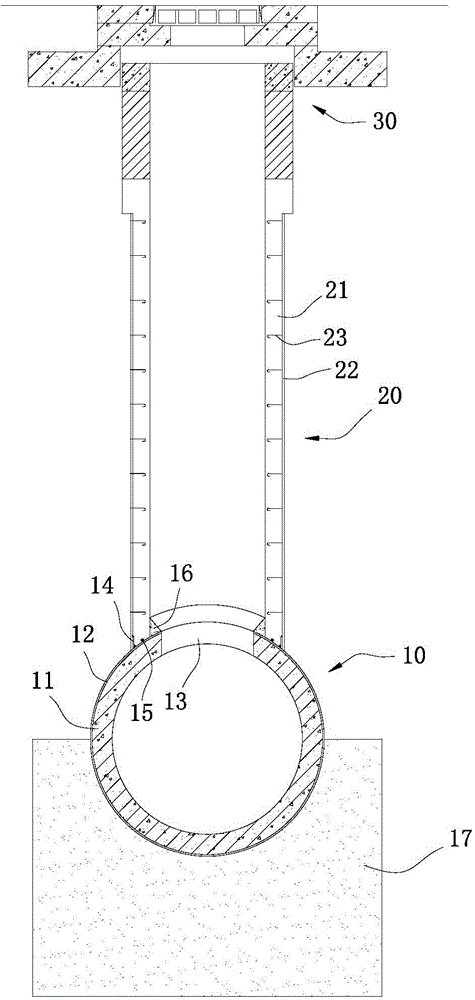

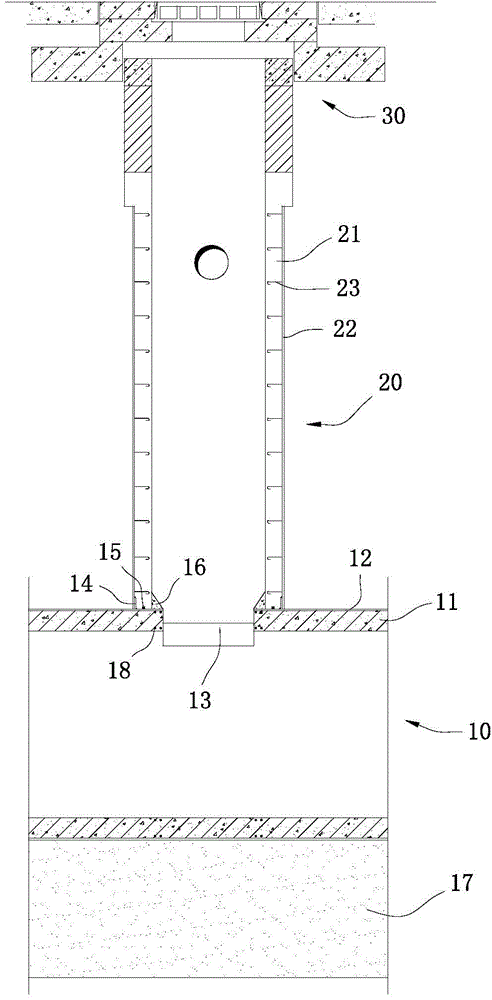

[0014] refer to figure 1 and figure 2 , a new type of inspection well between pipe jacking sections of the present invention, comprising a pipe jacking body 10, an inspection well body 20 and an inspection well seat 30, the pipe jacking body 10 includes a reinforced concrete pipe jacking 11 and is coated outside the reinforced concrete pipe jacking 11 The pipe jacking steel plate 12 on the surface, the pipe jacking body 10 is provided with a reserved hole 13 that is compatible with the maintenance well body 20, and the maintenance well body 20 includes a reinforced concrete shaft 21 and a shaft steel plate coated on the outer surface of the reinforced concrete shaft 21 22. The bottom end of the maintenance well body 20 is vertically connected to the reserved hole 13 of the pipe jacking body 10, and is welded and fixed at the intersection of the wellbore steel plate 22 and the pipe jacking steel plate 12.

[0015] In this embodiment, the pipe jacking body 10 is composed of re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com