High-base asphalt concrete core wall dam

A technology of asphalt concrete and core wall dam, which is applied to wall dams, dams, gravity dams, etc., can solve the problem of inability to correctly predict the deformation of the core wall, the requirements for the form of stress connection structure, and the inability to reach the 200m-level high asphalt concrete core wall rockfill. dam and other problems, to achieve the effect of improving the core wall stress, small deformation and small gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

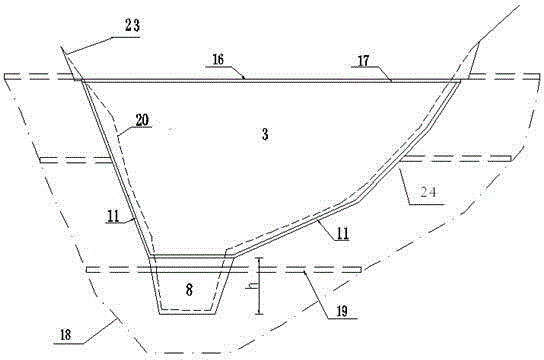

[0022] High base bituminous concrete core wall dam is composed of high base 8, core wall 3, base 11 of asphalt concrete cut-off wall, transition 1 zone 4, transition 2 zone 5, rockfill 1 zone 1, rockfill 2 zone 2, river bed The low-compression material area 7 and the anti-wave wall 6 are composed, the core wall 3 is set on the base 11 of the asphalt concrete cut-off wall, the base 11 of the asphalt concrete cut-off wall is set on the high base 8, and the top of the core wall 3, namely A wave wall 6 is set at the top of the dam; two transition 1 zones 4 are respectively set on the upstream side 21 and downstream side 22 of the core wall 3 and are in close contact with the core wall 3; transition 2 zones are set outside the two transition 1 zones 4 Zone 5; Transition 1 Zone 4, Transition 2 Zone 5 are equal in height to the core wall 3; the height of the high base 8 is above 10m.

Embodiment 2

[0024] Such as figure 1 and figure 2 As shown, the high base asphalt concrete core wall dam is composed of high base 8, core wall 3, base 11 of asphalt concrete cut-off wall, transition 1 zone 4, transition 2 zone 5, rockfill zone 1, rockfill zone 2 2. The riverbed low-compression material area 7 and the anti-wave wall 6 are composed. The core wall 3 is set on the base 11 of the asphalt concrete cut-off wall, and the base 11 of the asphalt concrete cut-off wall is set on the high base 8. The core wall 3 The top, that is, the dam crest is provided with a wave-proof wall 6; the two transition 1 zones 4 are respectively set on the upstream side 21 and the downstream side 22 of the core wall 3 and are closely attached to the core wall 3; There are transition 2 zones 5; transition 1 zone 4, transition 2 zone 5 are equal in height to the core wall 3, and the transition zone is protected by the dam shell; the height of the high base 8 is above 10m. The core wall 3 is an asphalt c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com