Method for adjusting molecular weight of polymer

A polymer molecular weight technology, applied in the field of polymer molecular weight adjustment, to achieve the effect of mild reaction conditions and simple and easy methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

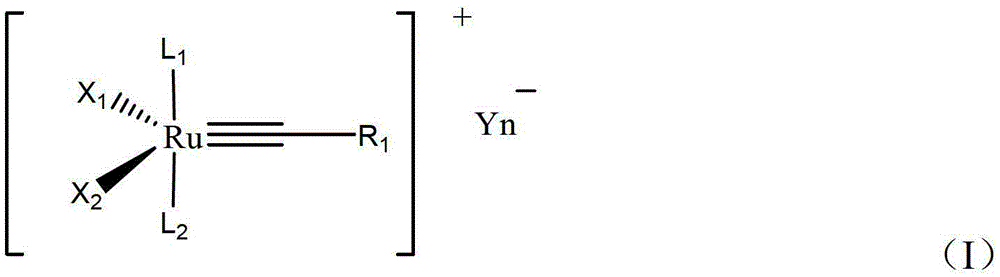

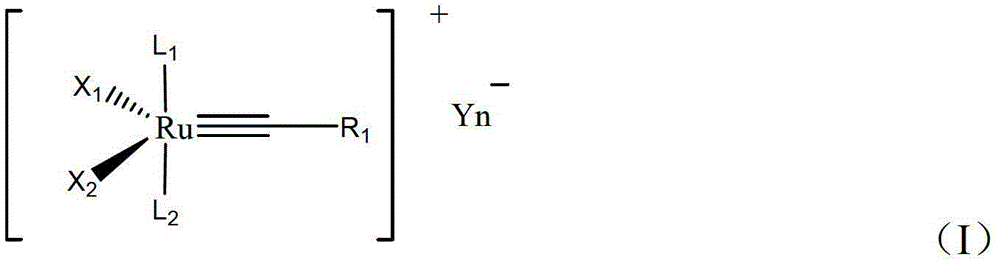

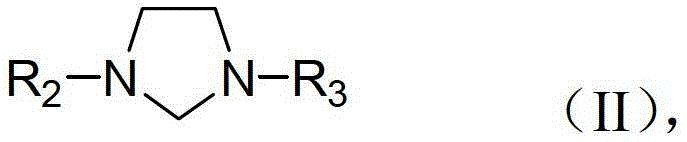

Method used

Image

Examples

Embodiment 1

[0057] (1) Preparation of catalyst

[0058] Under nitrogen protection, 760 mg of iodine, 848 mg of a compound represented by formula V (commercially purchased from Bailingwei Technology Co., Ltd.) and 20 mL of dichloromethane were added to a 100 mL three-necked flask, and stirred at room temperature (25°C) for 0.5 hours. The obtained mixture was separated by aluminum oxide column chromatography (the developing solvent was dichloromethane), and the obtained eluate was concentrated and washed with cyclohexane to obtain 1.31 g of a catalyst as a yellow solid. The obtained catalyst was subjected to H NMR spectroscopy ( 1 H-NMR) and carbon nuclear magnetic resonance ( 13 C-NMR) analysis, confirmed that the obtained catalyst has the structure shown in formula VI.

[0059] 1 H-NMR(400MHz,DMSO)δ(ppm):1.35-2.06(m,33H),1.81(s,18H),2.62(m,4H),6.11(d,1H),7.38-7.50(m,5H ),7.59-7.67(m,3H).

[0060] 13 C-NMR (100MHz, DMSO) δ (ppm): 24.8, 25.5, 26.2, 26.3, 26.4, 26.6, 31.9, 32.1, 129.1,...

Embodiment 2

[0067]5 g of butadiene-styrene copolymer (commercially purchased from Sinopec, brand Y031) was dissolved in 50 mL of toluene under nitrogen protection. After the dissolution was complete, 5 g of 1-decene was added thereto. After adding 15 mg of the catalyst prepared in step (1) of Example 1 to the reaction system, heat it to 100°C for reaction, react for 2 hours, stop the reaction, and dry under reduced pressure to remove the solvent. The molecular weights and molecular weight distributions of the polymers before and after the reaction are listed in Table 2.

[0068] Table 2

[0069]

Embodiment 3

[0071] The butadiene-styrene copolymer was treated in the same manner as in Example 2, except that the reaction was carried out at 40°C. The molecular weights and molecular weight distributions of the polymers before and after the reaction are listed in Table 3.

[0072] table 3

[0073]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com