Downward-transportation belt conveyor broken-belt grasping energy absorption device and energy absorption method

A technology of belt conveyors and energy-absorbing devices, which is applied in the direction of conveyor control devices, conveyor objects, transportation and packaging, etc., can solve problems that affect the secondary utilization of broken belts, endanger workers' lives, and broken belts, etc., to achieve Improve the secondary utilization rate, ensure the safety of personnel, and avoid the effect of strong impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

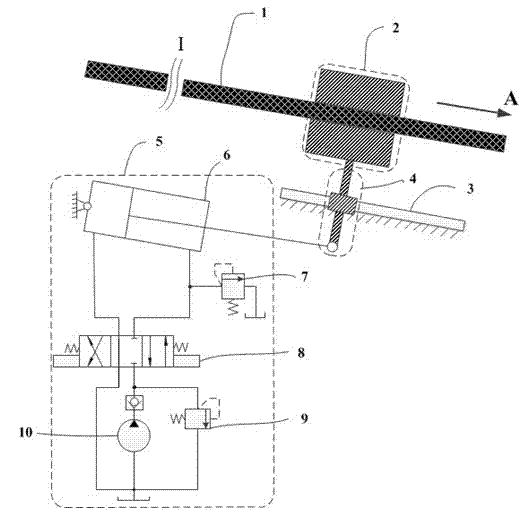

[0015] The direction of movement of the down belt conveyor is A, and the solenoid valve 8 is placed in the middle position. If the down belt 1 breaks at "I", the belt on the right side of the break will accelerate along the direction A, and the catch device 2 will grasp it tightly. After the fractured belt, the fracture of the belt will produce a great impact along the A direction. At this time, the catch device 2 acts on the energy absorbing device 5 through the guide device 4, so that the energy absorbing hydraulic cylinder 6 in the energy absorbing device 5 The pressure in the small chamber suddenly increases until it exceeds the set pressure of the pressure relief valve 7. At this time, the valve port of the pressure relief valve 7 is opened, the catch device 2 and the guide device 4 slide along the displacement device 3 in the direction A, and the energy-absorbing hydraulic cylinder 6 The piston rod stretches out, and the volume of the small chamber of the energy-absor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com